Experimental research on the preparation of expansion cementitious materials using municipal solid waste incineration fly ash

-

摘要:

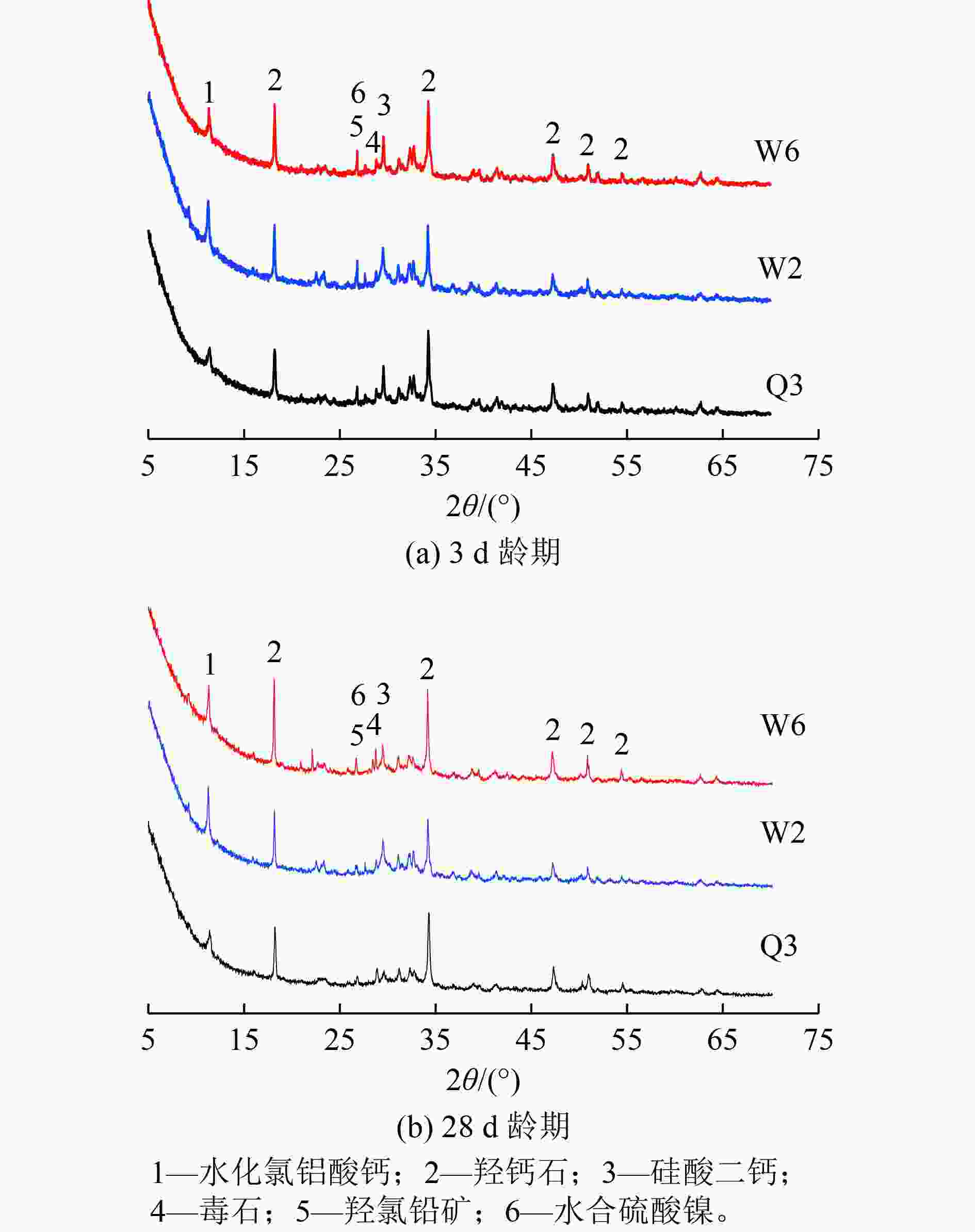

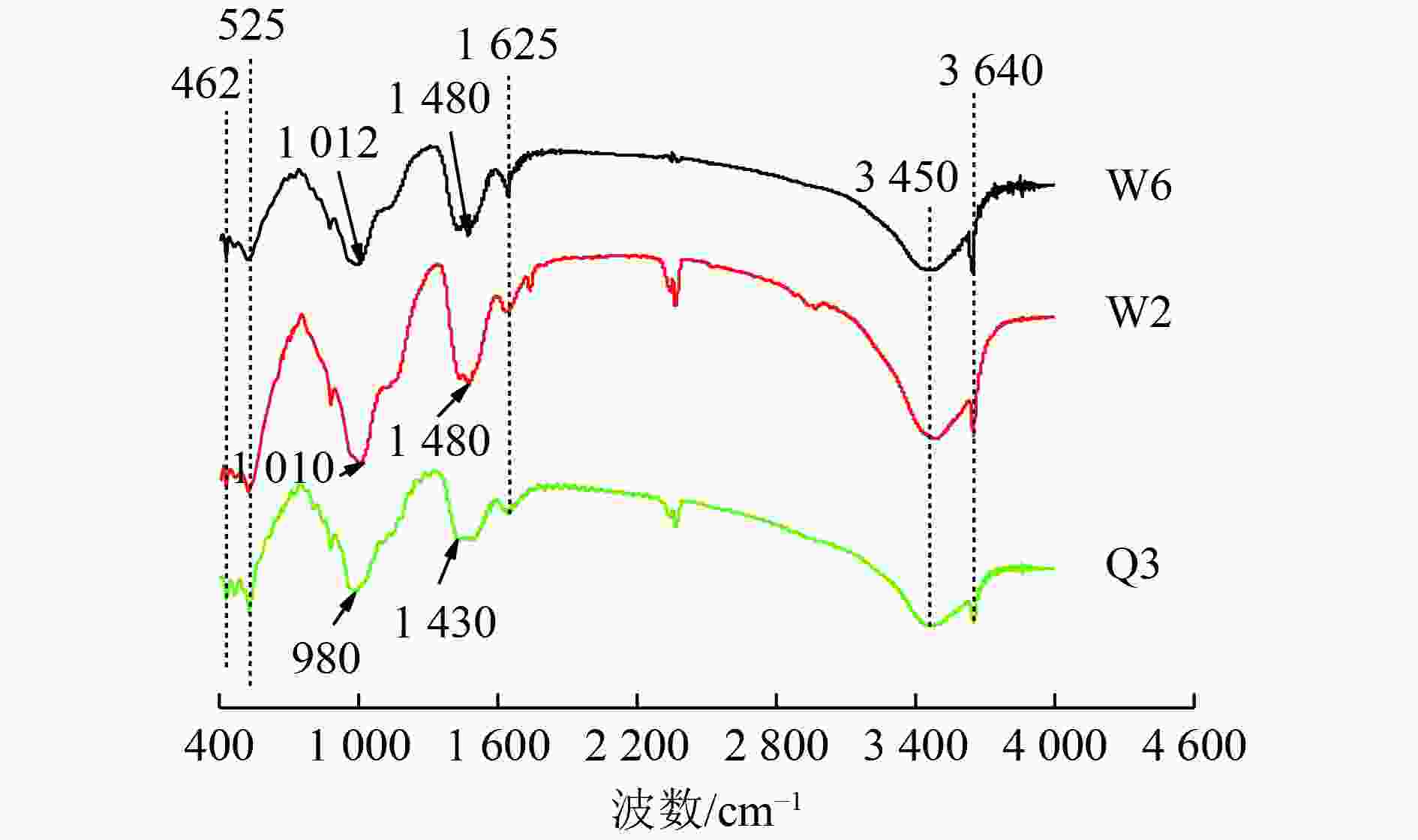

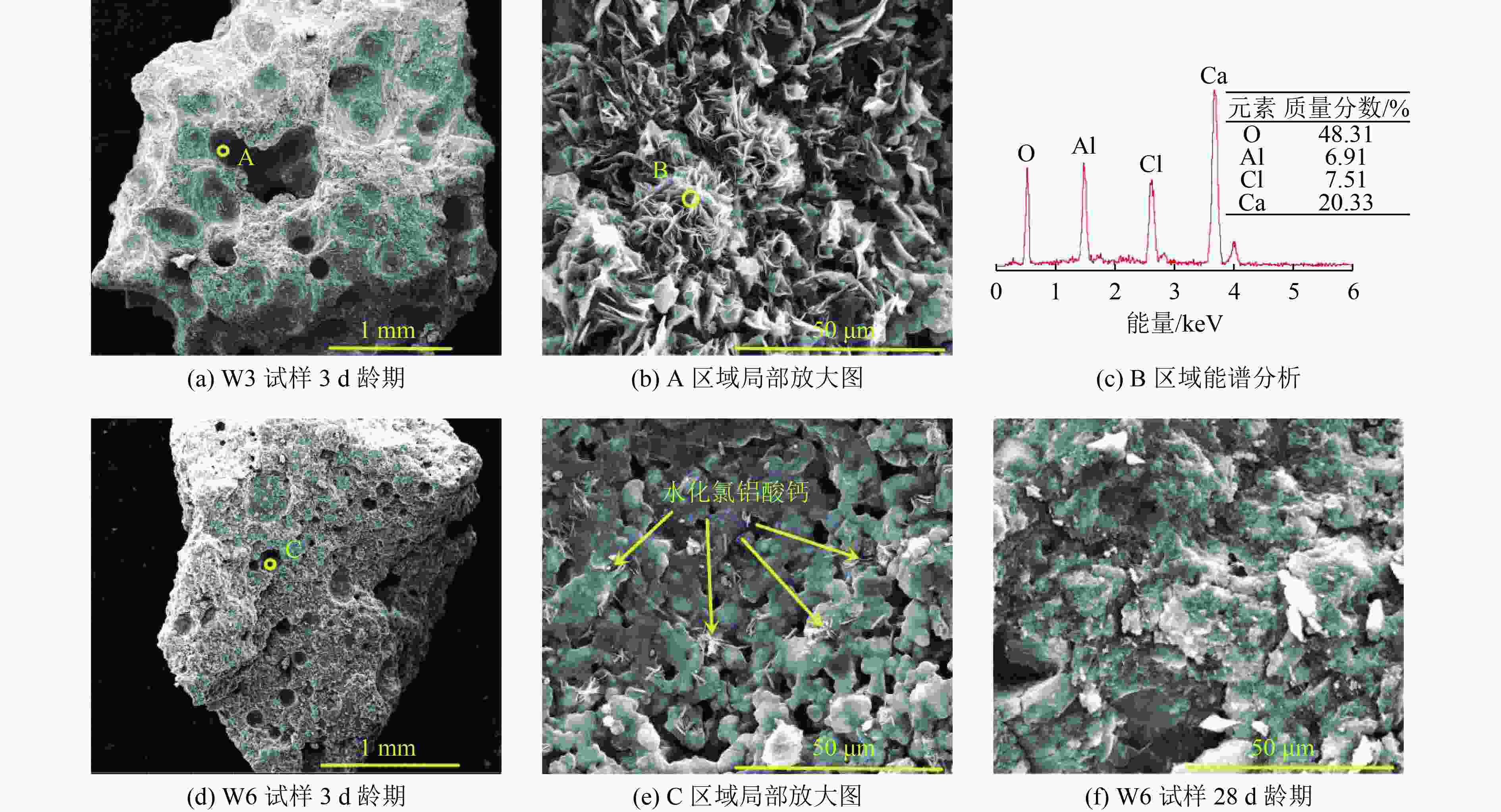

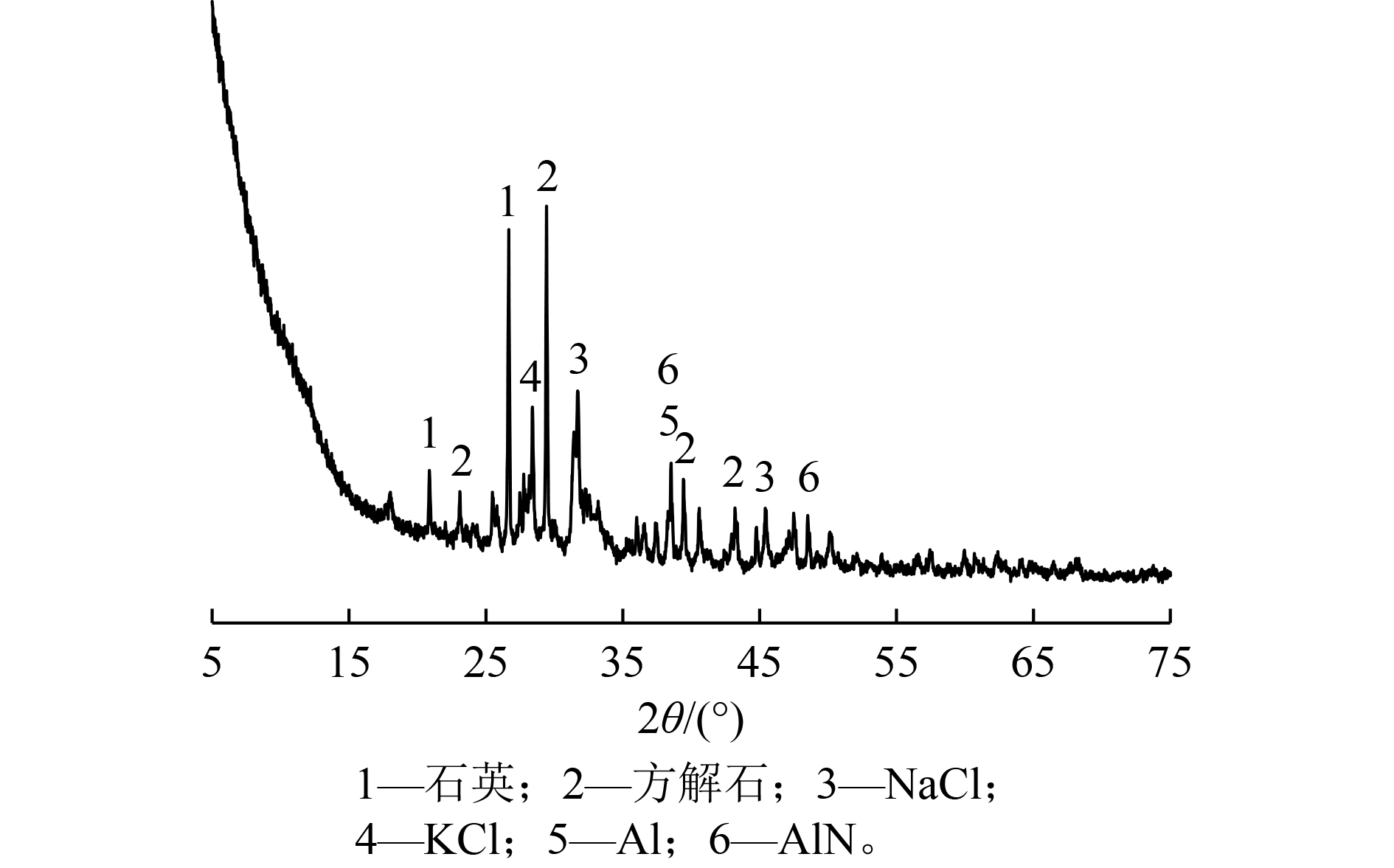

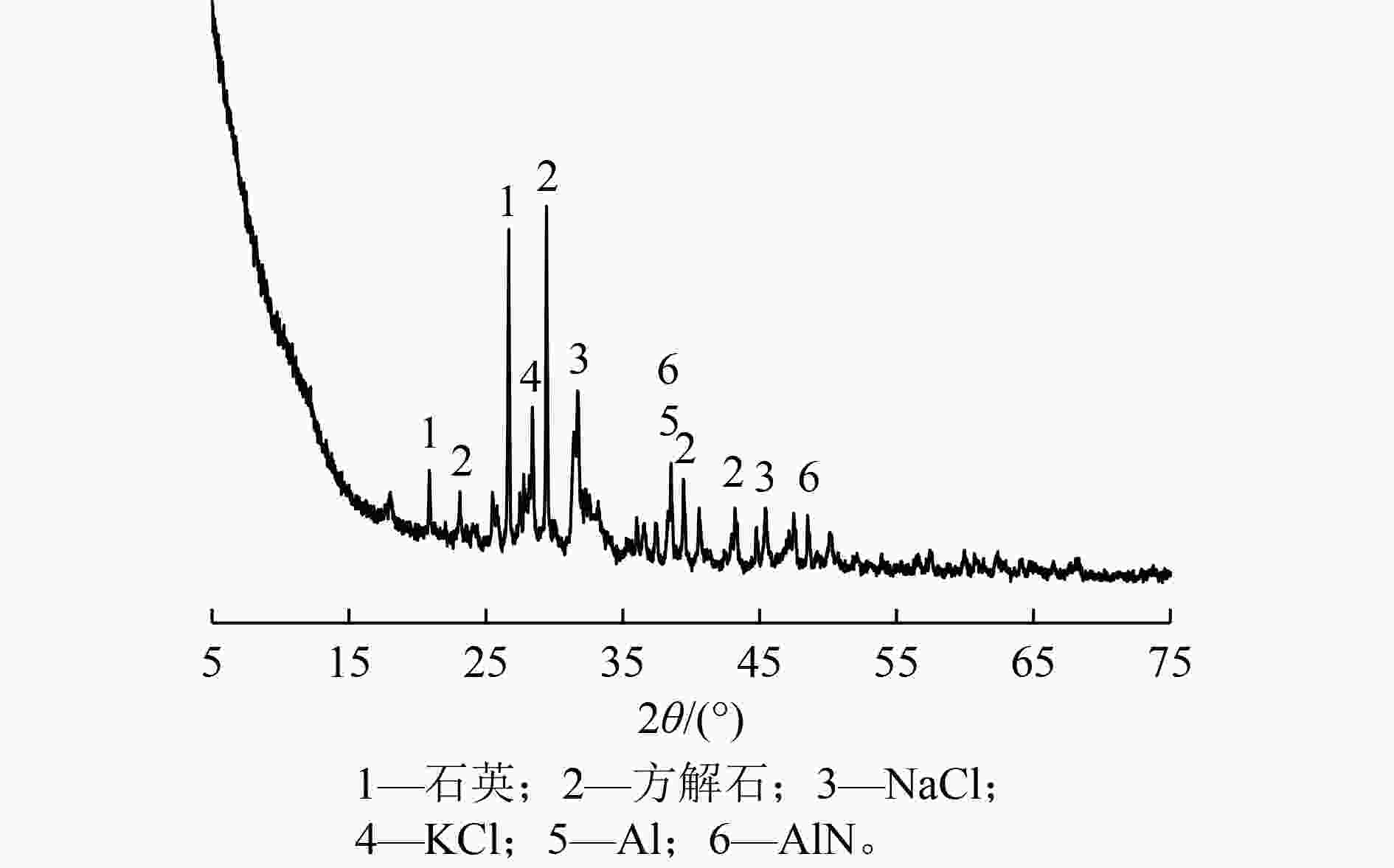

为实现生活垃圾焚烧飞灰在建材领域的大规模资源化利用,研究了飞灰掺量、水灰比以及外加剂对飞灰-水泥膨胀胶凝体系性能的影响,并对水化产物进行微观分析。结果表明:随着垃圾焚烧飞灰掺量的增加,飞灰-水泥料浆扩展度减小,凝结时间延长,抗压强度持续降低,膨胀率呈先增大后减小的趋势,且当飞灰掺量为60%时取得最大值;随着水灰比的增大,料浆扩展度、凝结时间及膨胀率均增加,水灰比取0.37~0.40较为合理。飞灰中的Al和氮化铝(AlN)与水反应生成气体导致胶凝材料产生膨胀,NaOH增加了溶液碱性,促使生成更多的气泡,提高了胶凝材料的膨胀性能;CaCl2促进了飞灰-水泥胶凝体系的水化反应,生成“云朵”状C—S(A)—H凝胶,凝胶微孔隙中填充簇状水化氯铝酸钙晶体,使得固化体结构更加密实,固化体抗压强度得以提高,同时极大地减小了重金属浸出及二噁英浓度。

Abstract:In order to realize large-scale resource utilization of municipal solid waste (MSW) incineration fly ash in the field of building materials, the effect of the addition ratio of fly ash, water-solid ratio and addition of admixtures on the performance of fly ash-cement expansion cementitious system was investigated, and the hydration products were analyzed microscopically. The results indicated that with the increasing content of MSW incineration fly ash, the dispersion degree of fly ash-cement slurry decreased, the setting time was prolonged, and the compressive strength decreased continuously. The expansion rate increased first and then decreased and reached maximum when the fly ash content was 60%. As the water-solid ratio of slurry increased, the dispersion degree, the setting time and the expansion rate of fly ash-cement slurry all increased, a more reasonable water-solid ratio between 0.37 and 0.40 should be considered. Al and aluminium nitride (AlN) in fly ash reacted with water to generate gas, leading to expansion of the cementitious material, NaOH increased the alkalinity of the solution, promoting the generation of more bubbles, and improved expansion of cementitious materials. CaCl2 promoted the hydration reaction of the fly ash-cement cementitious system, leading to the formation of "cloud" shaped C—S(A)—H gel, the gel micropores were filled with clusters of hydrated calcium aluminate chloride crystals, making the structure of the solidified body more compact, the compressive strength of the solidified body was improved, and the leaching content of heavy metals and dioxine concentration decreased.

-

表 1 生活垃圾焚烧飞灰的化学成分

Table 1. Chemical composition of municipal solid waste incineration fly ash

% SiO2 CaO Fe2O3 Al2O3 SO3 MgO P2O5 Na2O K2O TO2 烧失量 15.67 37.89 3.26 9.44 4.19 3.47 3.34 5.63 3.25 1.16 11.56 表 2 飞灰掺量及水灰比对胶凝材料性能的影响

Table 2. Effect of fly ash content and water-cement ratio on properties of the cementitious material

试验组

编号飞灰掺量/% 水灰比 扩展度/mm 凝结时间/min 抗压强度/MPa 膨胀率/% 初凝 终凝 3 d 28 d Q1 0 0.37 94 48 136 17.3 44.1 0 Q2 20 0.37 91 72 184 10.7 27.6 6.8 Q3 40 0.37 89 86 218 7.6 23.1 17.0 Q4 60 0.37 86 104 240 5.2 17.0 18.8 Q5 80 0.37 84 114 274 2.5 12.3 11.7 S1 40 0.34 72 58 152 11.9 29.0 2.8 S2 40 0.40 103 122 288 5.7 18.6 18.5 S3 40 0.43 112 138 310 3.1 13.1 19.7 S4 40 0.46 135 156 356 2.2 10.9 23.8 表 3 外加剂对胶凝材料性能的影响

Table 3. Effect of admixture on properties of the cementitious material

试验组

编号外加剂种类 外加剂掺量/% 扩展度/mm 凝结时间/min 抗压强度/MPa 膨胀率/% 初凝 终凝 3 d 28 d Q3 89 86 218 7.6 23.1 17.0 W1 NaOH 0.6 89 86 220 6.2 21.2 19.6 W2 1.2 88 90 224 4.1 15.9 21.4 W3 1.8 89 88 222 2.7 12.6 25.8 W4 CaCl2 1 90 68 172 8.8 26.2 17.5 W5 2 92 64 158 9.6 17.8 18.0 W6 3 93 52 124 10.9 18.2 18.8 表 4 垃圾焚烧飞灰原料及胶凝材料重金属浸出浓度

Table 4. Heavy metal leaching concentration of fly ash and cementitious materials

mg/L 元素 浸出液中重金属离子浓度 飞灰原料 Q3 W3 W6 GB 5085.3—

2007标准

限值GB 30760—

2014 水泥

熟料中限值Ni 8.53 0.13 0.18 0.11 5 0.2 Pb 32.45 0.25 0.53 0.18 5 0.3 Cd 4.86 0.01 0.02 0.007 1 0.03 As 7.34 0.04 0.1 0.02 5 0.1 -

[1] 刘彦君, 陈竞尧, 杨惠媛, 等. 生活垃圾初期降解过程中污染物释放及恶臭污染研究[J]. 环境科学研究,2022,35(1):238-245. doi: 10.13198/j.issn.1001-6929.2021.07.12LIU Y J, CHEN J Y, YANG H Y, et al. Emission of pollutants and odor pollution at initial decomposition stage of municipal solid waste[J]. Research of Environmental Sciences,2022,35(1):238-245. doi: 10.13198/j.issn.1001-6929.2021.07.12 [2] 郭梦茹, 张冰如, 席佳锐, 等. 垃圾分类前后焚烧飞灰的理化性质及重金属污染特性[J]. 环境工程技术学报,2022,12(3):843-850. doi: 10.12153/j.issn.1674-991X.20210560GUO M R, ZHANG B R, XI J R, et al. Physicochemical properties and heavy metal pollution characteristics of incineration fly ash before and after refuse classification[J]. Journal of Environmental Engineering Technology,2022,12(3):843-850. doi: 10.12153/j.issn.1674-991X.20210560 [3] ZHANG X, WANG B M, CHANG J, et al. Effect of zeolite contents on mineral evolution and heavy metal solidification in alkali-activated MSWI fly ash specimens[J]. Construction and Building Materials,2022,345:128309. doi: 10.1016/j.conbuildmat.2022.128309 [4] ZHAN X Y, WANG L A, WANG J, et al. Roasting mechanism of lightweight low-aluminum-silicon ceramisite derived from municipal solid waste incineration fly ash and electrolytic manganese residue[J]. Waste Management,2022,153:264-274. doi: 10.1016/j.wasman.2022.09.011 [5] 张元馨, 卢前明, 王震, 等. 利用微波烧结垃圾焚烧灰的实验研究[J]. 环境污染与防治,2022,44(7):862-867. doi: 10.15985/j.cnki.1001-3865.2022.07.004ZHANG Y X, LU Q M, WANG Z, et al. Experimental research on microwave sintering behavior of composite waste incineration ash[J]. Environmental Pollution and Control,2022,44(7):862-867. doi: 10.15985/j.cnki.1001-3865.2022.07.004 [6] 徐鹏程, 胡明, 许继云, 等. 生活垃圾焚烧飞灰等离子熔融过程氯元素的迁移转化特性研究[J]. 工程热物理学报,2022,43(7):1969-1975.XU P C, HU M, XU J Y, et al. Study on the transformation characteristics of chlorine during plasma vitrification of municipal solid waste incineration fly ash[J]. Journal of Engineering Thermophysics,2022,43(7):1969-1975. [7] 刘志伟. 不同膨胀剂对复合水泥封孔材料性能的影响[J]. 煤矿安全,2019,50(10):71-73.LIU Z W. Influence of different expansive agents on performance of composite cement sealing material[J]. Safety in Coal Mines,2019,50(10):71-73. [8] 李树刚, 张静非, 张超, 等. 新型CF封孔材料的膨胀作用机理及其关键影响因素实验研究[J]. 采矿与安全工程学报,2018,35(2):415-421.LI S G, ZHANG J F, ZHANG C, et al. Experimental study on expansion mechanism of new CF sealing material and the key influencing factors[J]. Journal of Mining and Safety Engineering,2018,35(2):415-421. [9] 马梦晓, 刘健, 吉小利, 等. 一种早强膨胀延迟封孔材料制备及性能研究[J]. 中国安全科学学报,2018,28(3):144-148.MA M X, LIU J, JI X L, et al. Preparation and properties of a kind of accelerating early strength delayed expansion mine sealing material[J]. China Safety Science Journal,2018,28(3):144-148. [10] 何立粮, 杨立荣, 张宝强. 水灰比和外加剂对泡沫混凝土性能的影响[J]. 混凝土与水泥制品,2015(10):71-73. doi: 10.3969/j.issn.1000-4637.2015.10.019HE L L, YANG L R, ZHANG B Q. Influence of water-cement ratio and admixture on properties of foamed concrete[J]. China Concrete and Cement Products,2015(10):71-73. doi: 10.3969/j.issn.1000-4637.2015.10.019 [11] 侯星, 薛群虎, 萧礼标, 等. 影响水泥基发泡保温材料孔结构的因素研究[J]. 硅酸盐通报,2015,34(8):2325-2329.HOU X, XUE Q H, XIAO L B, et al. Influence of factors on pore structure of the cement-based foam insulation material[J]. Bulletin of the Chinese Ceramic Society,2015,34(8):2325-2329. [12] 王莹, 倪文, 张思奇, 等. 含铝矿物相在胶凝体系中的水化机理研究进展[J]. 金属矿山,2019(4):194-198.WANG Y, NI W, ZHANG S Q, et al. Research status of hydration mechanism of alumino-based cementitious system[J]. Metal Mine,2019(4):194-198. [13] 简志强, 周高婷, 龚斌, 等. 微米零价铁去除磷酸盐效果与机理研究[J]. 环境工程技术学报,2021,11(5):927-934. doi: 10.12153/j.issn.1674-991X.20210027JIAN Z Q, ZHOU G T, GONG B, et al. Study on the efficacy of micron zero-valent iron on phosphate removal and its mechanism[J]. Journal of Environmental Engineering Technology,2021,11(5):927-934. doi: 10.12153/j.issn.1674-991X.20210027 [14] 丁益, 任启芳, 闻超. 发泡混凝土研制进展[J]. 混凝土,2011(10):13-15. doi: 10.3969/j.issn.1002-3550.2011.10.005DING Y, REN Q F, WEN C. Progress of research on foam concrete[J]. Concrete,2011(10):13-15. doi: 10.3969/j.issn.1002-3550.2011.10.005 [15] 卢前明, 王震, 张瑞林, 等. 化学外加剂对粉煤灰-矿渣-水泥胶凝体系的激发作用[J]. 硅酸盐通报,2018,37(8):2516-2521.LU Q M, WANG Z, ZHANG R L, et al. Excitation function of chemical admixture on fly ash-slag-cement cementitious system[J]. Bulletin of the Chinese Ceramic Society,2018,37(8):2516-2521. [16] 卢前明, 张元馨, 张瑞林, 等. 污泥灰-水泥胶凝体系的力学性能及微观分析[J]. 安全与环境学报,2019,19(1):308-313.LU Q M, ZHANG Y X, ZHANG R L, et al. Analysis of mechanical properties and microstructure of sludge-ash and cement cementitious system[J]. Journal of Safety and Environment,2019,19(1):308-313. [17] LU Q M, LI J X, ZHANG Y X, et al. Preparation of sludge ash-desulfurization gypsum-based backfill materials using microwave calcination[J]. Journal of Materials in Civil Engineering,2022,34(3):04021469. doi: 10.1061/(ASCE)MT.1943-5533.0004106 [18] 李启照. 新型聚氨酯/薄水铝石纳米复合膜的制备及气体渗透性能研究[J]. 膜科学与技术,2020,40(6):79-87.LI Q Z. Study on preparation and gas permeability of novel polyurethane/boehmite nanocomposite membrane[J]. Membrane Science and Technology,2020,40(6):79-87. [19] 杨柳, 胡海强, 任靖, 等. 拟薄水铝石性质及其胶溶性能研究[J]. 应用化工,2021,50(5):1311-1314. doi: 10.3969/j.issn.1671-3206.2021.05.033YANG L, HU H Q, REN J, et al. Study on the character of pseudo-boehmite and its peptizing property[J]. Applied Chemical Industry,2021,50(5):1311-1314. doi: 10.3969/j.issn.1671-3206.2021.05.033 [20] 卢前明, 王雪晴, 付少莙, 等. 脱硫石膏对污泥灰胶凝体系强度及微观结构的影响[J]. 郑州大学学报(工学版),2021,42(3):99-104.LU Q M, WANG X Q, FU S J, et al. Effect of desulphurization gypsum on the strength and microstructure of the sludge ash cementitious system[J]. Journal of Zhengzhou University (Engineering Science),2021,42(3):99-104. [21] 傅博, 杨长辉, 程臻赟. 高温对碱矿渣水泥石产物及微结构的影响[J]. 华中科技大学学报(自然科学版),2013,41(5):34-38.FU B, YANG C H, CHENG Z B. Influence of high temperature on microstructure of alkali-activated slag cement pastes[J]. Journal of Huazhong University of Science and Technology (Nature Science Edition),2013,41(5):34-38. [22] 马保国, 单志欣, 谭洪波, 等. 不同细度的铝酸三钙对氯离子固化能力的影响[J]. 武汉理工大学学报,2017,39(12):1-6.MA B G, SHAN Z X, TAN H B, et al. Influence of the fineness of tricalcium aluminate on chloride ion binding capability[J]. Journal of Wuhan University of Technology,2017,39(12):1-6. [23] 唐强, 陈辉, 尹立新, 等. 生活垃圾焚烧飞灰固化体力学及重金属浸出特性[J]. 环境工程,2017,35(4):111-114.TANG Q, CHEN H, YIN L X, et al. Mechanics and leaching characteristics of heavy metals in stabilized mswi fly ash[J]. Environmental Engineering,2017,35(4):111-114. [24] 王宇珊, 黄道建, 陈继鑫, 等. 某垃圾焚烧厂投产前后周边土壤二噁英类化合物的分布[J]. 环境科学研究,2020,33(8):1938-1945. doi: 10.13198/j.issn.1001-6929.2020.02.14WANG Y S, HUANG D J, CHEN J X, et al. Distribution of pcddfs in soil before and after operation of municipal solid waste incinerator[J]. Research of Environmental Sciences,2020,33(8):1938-1945. doi: 10.13198/j.issn.1001-6929.2020.02.14 [25] 陈晓晨, 尧聪聪, 赵桐, 等. 水化氯铝酸钙对土壤铬的钝化修复及风险评估[J]. 中国环境科学,2021,41(4):1790-1798.CHEN X C, YAO C C, ZHAO T, et al. Immobilization remediation of Cr-contaminated soils by hydrocalumite and the relevant risk assessment[J]. China Environmental Science,2021,41(4):1790-1798. ⊗ -

下载:

下载: