Review of research on VOCs treatment by gliding arc plasma

-

摘要:

滑动弧等离子体兼具热等离子体和冷等离子体的优势,在挥发性有机物(VOCs)的去除中展现了很好的应用前景。在阐述滑动弧等离子体产生原理及基本特性的基础上,介绍了现有各种类型的滑动弧发生器及其特点。通过对国内外相关文献的归纳和整理,总结了影响滑动弧等离子体处理VOCs效率的关键影响因素以及不同类型滑动弧反应器去除VOCs的性能差异。最后,对滑动弧等离子体净化VOCs机理进行了探讨,并展望了该技术今后的研究方向。

Abstract:Gliding arc plasma combines the advantages of both thermal and cold plasma, showing great application prospects in volatile organic compounds (VOCs) removal. Various types of gliding arc generators and their characteristics were introduced based on the exposition of the generation principle and basic properties of gliding arc plasma. By summarizing and collating the relevant literature at home and abroad, the key factors affecting the removal efficiency of VOCs and the differences in the performance of different gliding arc reactors in VOCs abatement were summarized. Finally, the mechanism of VOCs purification by gliding arc plasma was discussed and the future research directions of this technology were prospected.

-

Key words:

- gliding arc discharge /

- volatile organic compounds /

- degradation /

- mechanism

-

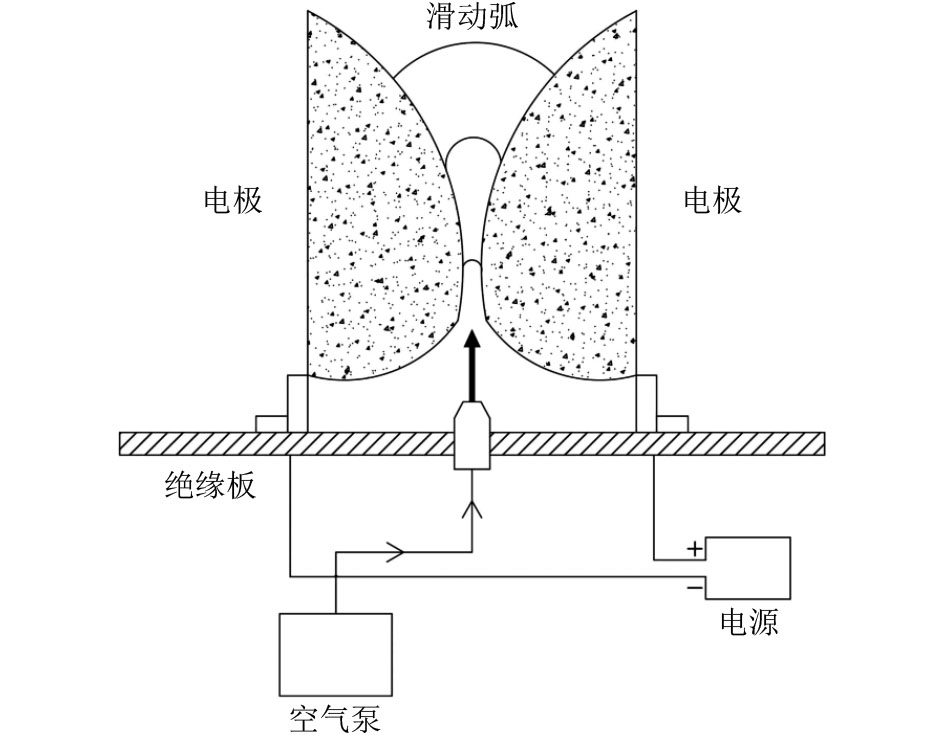

图 1 刀片式滑动弧放电结构[21]

Figure 1. Structure of conventional blade type sliding arc reactor

图 2 切向进气旋转滑动弧的产生和电弧伸展过程[24]

Figure 2. Generation and extension process of rotating gliding arc driven by tangential flow

图 3 磁场驱动旋转滑动弧原理[25]

1—阳极; 2—阴极;3—起弧金属线。

Figure 3. Schematic diagram of rotating gliding arc driven by magnetic field

图 4 龙卷风滑动弧放电示意[26]

Figure 4. Schematic diagram of tornado gliding arc discharge

图 5 六电极滑动弧系统[29]

Figure 5. Photo of six electrode gliding arc system

表 1 不同类型滑动弧等离子体降解VOCs性能与参数的比较

Table 1. Degradation performance and parameter comparison of various gliding arc plasma for VOCs destruction

滑动弧类型 VOCs种类 载气 浓度/(g/m3) 流速/(L/min) 去除率/% 能量效率/〔g/(kW·h)〕 数据来源 刀片式滑动弧 甲苯 空气 1.47 30 60 3.1 文献[37] 甲苯 氮气、水蒸气 9.5~23.4 3.5 >35 32.1~46.3 文献[35] 甲苯 氮气、氧气、二氧化碳、水蒸气 14.8 3.5 78.3 69.5 文献[41] 甲苯 空气 12.0 13 78 36.6 文献[31] 甲苯 空气、二氧化碳 7.0 17 53 22.2 文献[42] 苯、甲苯、二甲苯 空气 4.0~20.0 5 >40 8.4~19.0 文献[43] 苯 空气 30.0 2~4.5 73 87.8 文献[44] 二甲苯 空气 0.7 2000 81 5.0 文献[45] 蒽、芘 空气、氮气、

氧气、氩气0.67 6.8 92.3 3.6 文献[46] 甲苯、萘 氮气 2~22 4 60~86 2.6~21.1 文献[39] 切向进气旋转滑动弧 甲苯 空气 0.2~2.0 90 77 2.1~15.2 文献[32] 甲苯、萘、菲 氮气、二氧化碳 12.0 12 >84 10.2 文献[36] 磁驱动旋转滑动弧 甲苯 氮气 14.0 10 >80 16.6 文献[33] 甲苯、萘 氮气、二氧化碳 26.0 6 >70 21.3 文献[38] 龙旋风滑动弧 硫化氢 硫化氢 — 2~14 — — 文献[27] 六氯苯 飞灰 4.5~16.5×10−3 13 66~72 — 文献[47] 多电极滑动弧 甲苯 空气 7.3 33.3 92 16.6 文献[48] 庚烷 空气 9.4 30 100 16.6 文献[48] 丁酮 空气 6.4 53.3 66 10.0 文献[48] 四氯乙烯 空气 3.6 31.6 100 1.1 文献[48] 苯 氮气 8.0 16.7 82 42.1 文献[34] 芘 氮气 0.13 12 88 0.13 文献[49] 蒽 氮气 0.21 10 96 1.14 文献[50] 表 2 滑动弧等离子体去除VOCs的放大试验

Table 2. Scaled-up experiments of gliding arc plasma for VOCs abatement

规模 装置 处理对象 处理量/

(m3/h)去除

率/%能耗/

(kW·h/m3)实验室规模 刀片式滑动弧 甲苯 2 >98 0.42 中试规模 刀片式滑动弧 二甲苯 120 >90 0.1 多电极滑动弧 丙烷、丁烷 80 >54 0.044 多电极滑动弧

(六段式串联)三硝基甲苯 50 >95 0.06 工业规模 多电极滑动弧

(活性炭吸附再生+四组并联三组串联)苯、甲苯、二甲苯、甲醛 25 000 >80 0.001 -

[1] 郝小龙, 石朝阳, 张一波. 大气压等离子体射流在环境领域的应用进展[J]. 环境工程技术学报,2023,13(4):1415-1424. doi: 10.12153/j.issn.1674-991X.20220815HAO X L, SHI C Y, ZHANG Y B. Progress in the application of atmospheric pressure plasma jets in environmental field[J]. Journal of Environmental Engineering Technology,2023,13(4):1415-1424. doi: 10.12153/j.issn.1674-991X.20220815 [2] 竹涛, 李坚, 梁文俊, 等. 等离子体联合技术处理挥发性有机化合物废气的研究进展[J]. 化工环保,2008,28(2):118-121. doi: 10.3969/j.issn.1006-1878.2008.02.007ZHU T, LI J, LIANG W J, et al. Research progresses in treatment of waste gas containing volatile organic compounds by combined plasma technology[J]. Environmental Protection of Chemical Industry,2008,28(2):118-121. doi: 10.3969/j.issn.1006-1878.2008.02.007 [3] van DURME J, DEWULF J, SYSMANS W, et al. Abatement and degradation pathways of toluene in indoor air by positive corona discharge[J]. Chemosphere,2007,68(10):1821-1829. doi: 10.1016/j.chemosphere.2007.03.053 [4] SCHIORLIN M, MAROTTA E, REA M, et al. Comparison of toluene removal in air at atmospheric conditions by different Corona discharges[J]. Environmental Science & Technology,2009,43(24):9386-9392. [5] BYEON J H, PARK J H, JO Y S, et al. Removal of gaseous toluene and submicron aerosol particles using a dielectric barrier discharge reactor[J]. Journal of Hazardous Materials,2010,175(1/2/3):417-422. [6] MUSTAFA M F, FU X D, LIU Y J, et al. Volatile organic compounds (VOCs) removal in non-thermal plasma double dielectric barrier discharge reactor[J]. Journal of Hazardous Materials,2018,347:317-324. doi: 10.1016/j.jhazmat.2018.01.021 [7] SHIH S, LIN T, SHIH M. Decomposition of benzene in the RF plasma environment: part I. formation of gaseous products and carbon depositions[J]. Journal of Hazardous Materials,2004,116(3):239-248. doi: 10.1016/j.jhazmat.2004.09.006 [8] JOSHI A V. Decomposition of SF6-R134a effluents by RF plasma[J]. Nuclear Instruments and Methods in Physics Research Section A: Accelerators, Spectrometers, Detectors and Associated Equipment, 2012, 661: S245-S248. [9] 李瑞娜. 常压下微波等离子体去除三氯乙烯的研究[D]. 大连: 大连海事大学, 2011. [10] KO Y, YANG G, CHANG D P Y, et al. Microwave plasma conversion of volatile organic compounds[J]. Journal of the Air & Waste Management Association,2003,53(5):580-585. [11] RUBIO S J, QUINTERO M C, RODERO A. Application of microwave air plasma in the destruction of trichloroethylene and carbon tetrachloride at atmospheric pressure[J]. Journal of Hazardous Materials,2011,186(1):820-826. doi: 10.1016/j.jhazmat.2010.11.069 [12] YAN J H, BO Z, LI X D, et al. Study of mechanism for hexane decomposition with gliding arc gas discharge[J]. Plasma Chemistry and Plasma Processing,2007,27(2):115-126. doi: 10.1007/s11090-006-9037-z [13] KRAWCZYK K, ULEJCZYK B. Decomposition of chloromethanes in gliding discharges[J]. Plasma Chemistry and Plasma Processing,2003,23(2):265-281. doi: 10.1023/A:1022916018245 [14] 夏诗杨, 米俊锋, 杜胜男, 等. 低温等离子体处理挥发性有机物的研究进展[J]. 应用化工,2021,50(4):1130-1135. doi: 10.3969/j.issn.1671-3206.2021.04.055XIA S Y, MI J F, DU S N, et al. Research progress of non-thermal plasma treatment of volatile organic compounds[J]. Applied Chemical Industry,2021,50(4):1130-1135. doi: 10.3969/j.issn.1671-3206.2021.04.055 [15] 薄拯. 滑动弧放电等离子体处理挥发性有机化合物基础研究[D]. 杭州: 浙江大学, 2008. [16] 阮建军, 潘维龙, 施耀. 非平衡等离子体脱臭技术研究进展[J]. 化工进展,2006,25(1):35-38. doi: 10.3321/j.issn:1000-6613.2006.01.007RUAN J J, PAN W L, SHI Y. Research advances of nonthermal plasma for odor removal[J]. Chemical Industry and Engineering Progress,2006,25(1):35-38. doi: 10.3321/j.issn:1000-6613.2006.01.007 [17] 王勇. 滑动弧等离子体降解氯苯类有机污染物的实验研究[D]. 杭州: 浙江大学, 2013. [18] LESUEUR H, CZERNICHOWSKI A, CHAPELLE J. Device for generating low-temperature plasmas by formation of sliding electric discharges: FR19880014932 [P]. 1988-11-17. [19] FRIDMAN A, NESTER S, KENNEDY L A, et al. Gliding arc gas discharge[J]. Progress in Energy and Combustion Science,1999,25(2):211-231. doi: 10.1016/S0360-1285(98)00021-5 [20] 严建华, 杜长明, CHERON B G, 等. 滑动弧等离子体技术用于环境治理领域的研究进展[J]. 热力发电,2005,34(5):1-6. doi: 10.3969/j.issn.1002-3364.2005.05.001YAN J H, DU C M, CHERON B G, et al. Advancement of study on application of gliding arc plasma in the domain of environmental protection[J]. Thermal Power Generation,2005,34(5):1-6. doi: 10.3969/j.issn.1002-3364.2005.05.001 [21] GONG X J, LIN Y C, LI X D, et al. Decomposition of volatile organic compounds using gliding arc discharge plasma[J]. Journal of the Air & Waste Management Association,2020,70(2):138-157. [22] 余量. 滑动弧放电等离子体降解芳香烃类有机污染物的基础研究[D]. 杭州: 浙江大学, 2011. [23] 林启富. 交/直流多弧等离子体特性及其应用研究[D]. 合肥: 中国科学技术大学, 2020. [24] LEE D H, KIM K T, CHA M S, et al. Effect of excess oxygen in plasma reforming of diesel fuel[J]. International Journal of Hydrogen Energy,2010,35(10):4668-4675. doi: 10.1016/j.ijhydene.2010.02.091 [25] OMBRELLO T, QIN X, JU Y G, et al. Combustion enhancement via stabilized piecewise nonequilibrium gliding arc plasma discharge[J]. AIAA Journal,2006,44(1):142-150. doi: 10.2514/1.17018 [26] FRIDMAN A, KALRA C S, KOSSITSYN M, et al. Electrical discharges in the reverse vortex flow-tornado discharges[R]. Taormina: Proceedings of 16th International Symposium on Plasma Chemistry, 2003. [27] NUNNALLY T, GUTSOL K, RABINOVICH A, et al. Dissociation of H2S in non-equilibrium gliding arc "tornado" discharge[J]. International Journal of Hydrogen Energy,2009,34(18):7618-7625. doi: 10.1016/j.ijhydene.2009.07.045 [28] GALLAGHER M J, GEIGER R, POLEVICH A, et al. On-board plasma-assisted conversion of heavy hydrocarbons into synthesis gas[J]. Fuel,2010,89(6):1187-1192. doi: 10.1016/j.fuel.2009.11.039 [29] BABA T, TAKEUCHI Y, STRYCZEWSKA H, et al. Study of 6 electrodes gliding arc discharge configuration[J]. Przeglad Elektrotechniczny,2012,88(6):86-88. [30] SREETHAWONG T, THAKONPATTHANAKUN P, CHAVADEJ S. Partial oxidation of methane with air for synthesis gas production in a multistage gliding arc discharge system[J]. International Journal of Hydrogen Energy,2007,32(8):1067-1079. doi: 10.1016/j.ijhydene.2006.07.013 [31] DU C M, YAN J H, CHERON B. Decomposition of toluene in a gliding arc discharge plasma reactor[J]. Plasma Sources Science and Technology,2007,16(4):791-797. doi: 10.1088/0963-0252/16/4/014 [32] LU S Y, SUN X M, LI X D, et al. Decomposition of toluene in a rotating glidarc discharge reactor[J]. IEEE Transactions on Plasma Science,2012,40(9):2151-2156. doi: 10.1109/TPS.2012.2206119 [33] ZHU F S, LI X D, ZHANG H, et al. Destruction of toluene by rotating gliding arc discharge[J]. Fuel,2016,176:78-85. doi: 10.1016/j.fuel.2016.02.065 [34] CHUN Y N, KIM S C, YOSHIKAWA K. Decomposition of benzene as a surrogate tar in a gliding arc plasma[J]. Environmental Progress & Sustainable Energy,2013,32(3):837-845. [35] LIU S Y, MEI D H, WANG L, et al. Steam reforming of toluene as biomass tar model compound in a gliding arc discharge reactor[J]. Chemical Engineering Journal,2017,307:793-802. doi: 10.1016/j.cej.2016.08.005 [36] KONG X Z, ZHANG H, LI X D, et al. Destruction of toluene, naphthalene and phenanthrene as model tar compounds in a modified rotating gliding arc discharge reactor[J]. Catalysts,2018,9(1):19. doi: 10.3390/catal9010019 [37] BO Z, YAN J H, LI X D, et al. Scale-up analysis and development of gliding arc discharge facility for volatile organic compounds decomposition[J]. Journal of Hazardous Materials,2008,155(3):494-501. doi: 10.1016/j.jhazmat.2007.11.105 [38] XU R Y, ZHU F S, ZHANG H, et al. Simultaneous removal of toluene, naphthalene, and phenol as tar surrogates in a rotating gliding arc discharge reactor[J]. Energy & Fuels,2020,34(2):2045-2054. [39] ZHANG H, ZHU F S, LI X D, et al. Steam reforming of toluene and naphthalene as tar surrogate in a gliding arc discharge reactor[J]. Journal of Hazardous Materials,2019,369:244-253. doi: 10.1016/j.jhazmat.2019.01.085 [40] LEE D H, KIM K T, CHA M S, et al. Optimization scheme of a rotating gliding arc reactor for partial oxidation of methane[J]. Proceedings of the Combustion Institute,2007,31(2):3343-3351. doi: 10.1016/j.proci.2006.07.230 [41] MEI D H, ZHANG P, LIU S Y, et al. Highly efficient reforming of toluene to syngas in a gliding arc plasma reactor[J]. Journal of the Energy Institute,2021,98:131-143. doi: 10.1016/j.joei.2021.06.005 [42] FERENC Z, WANDRASZ J W. Use of glidarc reactor for decomposition of toluene vapours in hot exhausts[J]. High Temperature Material Processes (an International Quarterly of High-Technology Plasma Processes),2004,8(1):31-38. doi: 10.1615/HighTempMatProc.v8.i1.30 [43] INDARTO A, YANG D R, AZHARI C H, et al. Advanced VOCs decomposition method by gliding arc plasma[J]. Chemical Engineering Journal,2007,131(1/2/3):337-341. [44] RAD R H, KHANI M R, MEHDIKIA H, et al. Decomposition of high concentration benzene (produced in paper and painting industries) and its byproducts, methane and carbon dioxide, using plate gliding arc[J]. Journal of Environmental Health Science and Engineering,2019,17(2):549-560. doi: 10.1007/s40201-019-00369-8 [45] CZERNICHOWSKI A. Gliding arc: applications to engineering and environment control[J]. Pure and Applied Chemistry,1994,66(6):1301-1310. doi: 10.1351/pac199466061301 [46] YU L, TU X, LI X D, et al. Destruction of acenaphthene, fluorene, anthracene and pyrene by a dc gliding arc plasma reactor[J]. Journal of Hazardous Materials,2010,180(1/2/3):449-455. [47] 程奎. 龙旋风滑动弧放电等离子体降解垃圾焚烧飞灰中二噁英的研究[D]. 杭州: 浙江大学, 2012. [48] CZERNICHOWSKI A, RANAIVOSOLOARIMANANA A. Zapping VOCs with a discontinuous electric arc[J]. Chemtech,1996,26(4):45-49. [49] CHUN Y N, KIM S C, YOSHIKAWA K. Destruction of biomass tar using a gliding arc plasma reformer[J]. International Journal of Environmental Protection,2012,2(12):1-8. [50] CHUN Y N, KIM S C, YOSHIKAWA K. Destruction of anthracene using a gliding arc plasma reformer[J]. Korean Journal of Chemical Engineering,2011,28(8):1713-1720. doi: 10.1007/s11814-011-0162-x [51] 杜长明. 低温等离子体净化有机废气技术[M]. 北京: 化学工业出版社, 2017: 138. [52] KOHNO H, BEREZIN A A, CHANG J S, et al. Destruction of volatile organic compounds used in a semiconductor industry by a capillary tube discharge reactor[J]. IEEE Transactions on Industry Applications,1998,34(5):953-966. doi: 10.1109/28.720435 [53] ZHANG H, WANG W Z, LI X D, et al. Plasma activation of methane for hydrogen production in a N2 rotating gliding arc warm plasma: a chemical kinetics study[J]. Chemical Engineering Journal,2018,345:67-78. doi: 10.1016/j.cej.2018.03.123 [54] XIA D H, LI Z Y, XIE Y L, et al. Kinetic simulations of volatile organic compounds decomposition by non-thermal plasma treatment[J]. Water, Air, & Soil Pollution, 2016, 227(12): 463. [55] BO Z, YAN J H, LI X D, et al. Effects of oxygen and water vapor on volatile organic compounds decomposition using gliding arc ga6 discharge[J]. Plasma Chemistry and Plasma Processing,2007,27(5):546-558. doi: 10.1007/s11090-007-9081-3 [56] 颜欣. 磁旋滑动弧等离子体裂解生活垃圾气化焦油的实验研究[D]. 杭州: 浙江大学, 2018. [57] ZHANG L D, CAI J H, ZHANG T C, et al. Kinetic modeling study of toluene pyrolysis at low pressure[J]. Combustion and Flame,2010,157(9):1686-1697. □ doi: 10.1016/j.combustflame.2010.04.002 -

下载:

下载: