Adsorption efficiency and mechanism of uranium in seepage of uranium tailing pond using biochar prepared from oxytetracycline fermentation residues at high temperature

-

摘要:

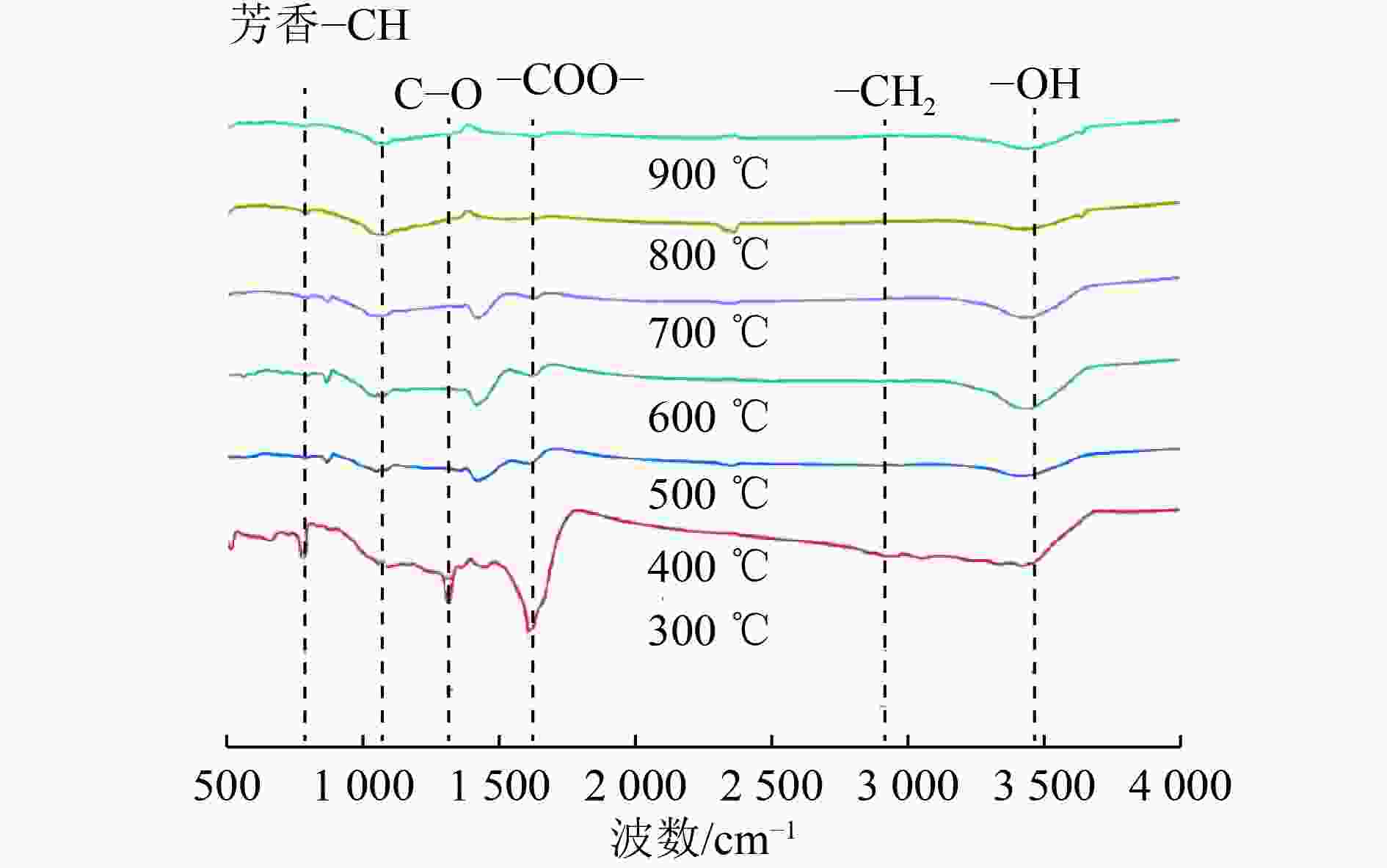

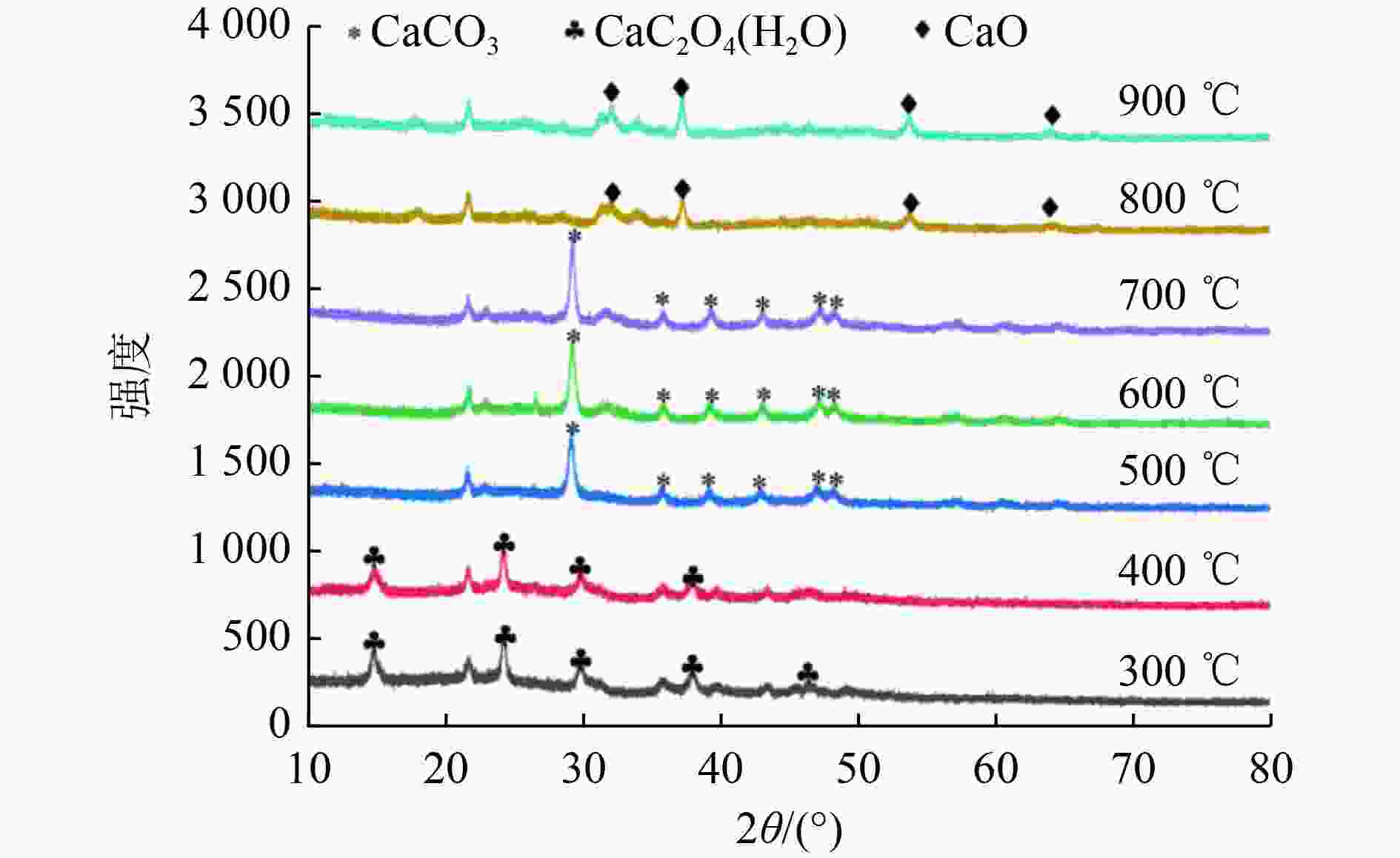

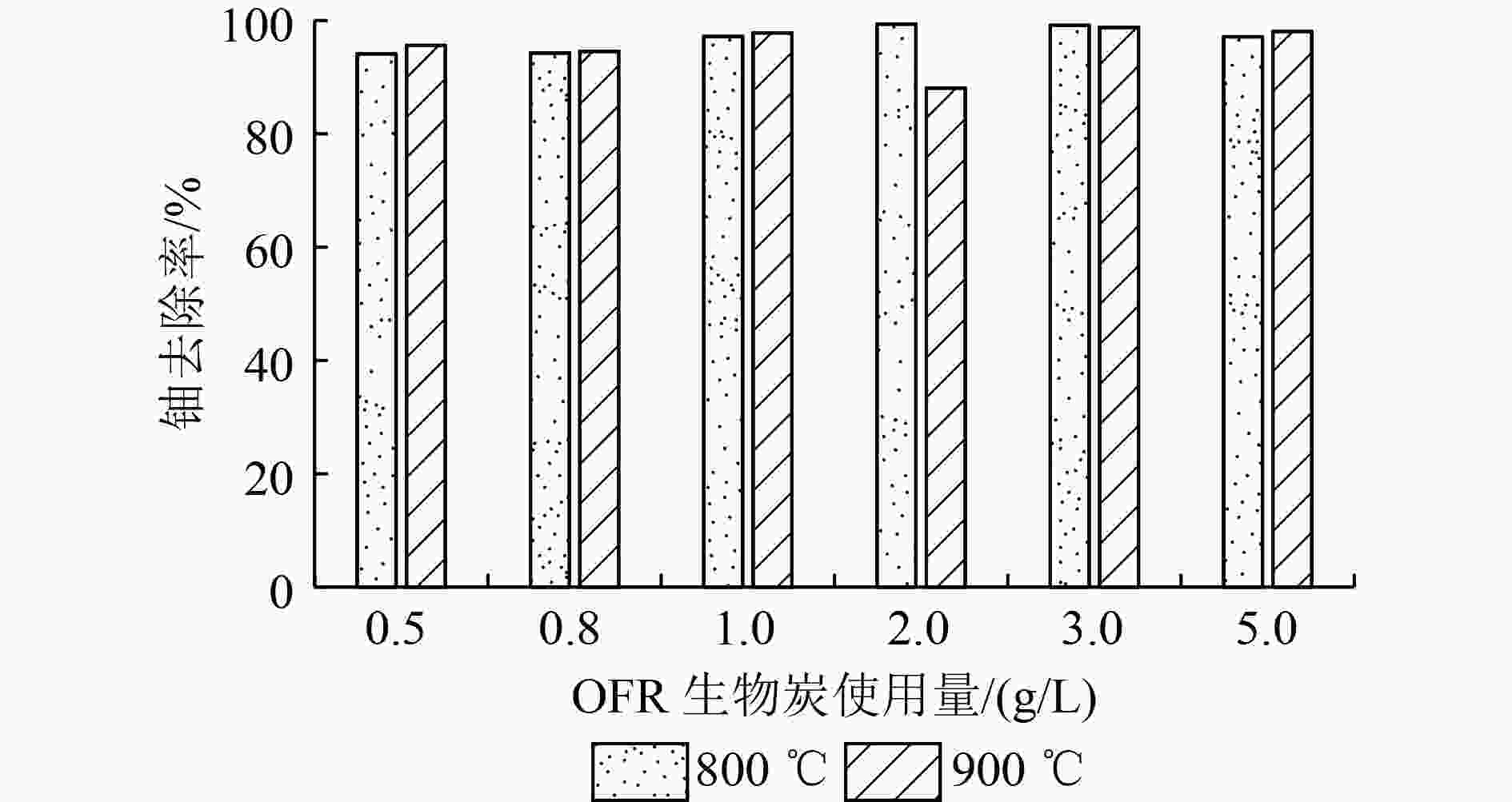

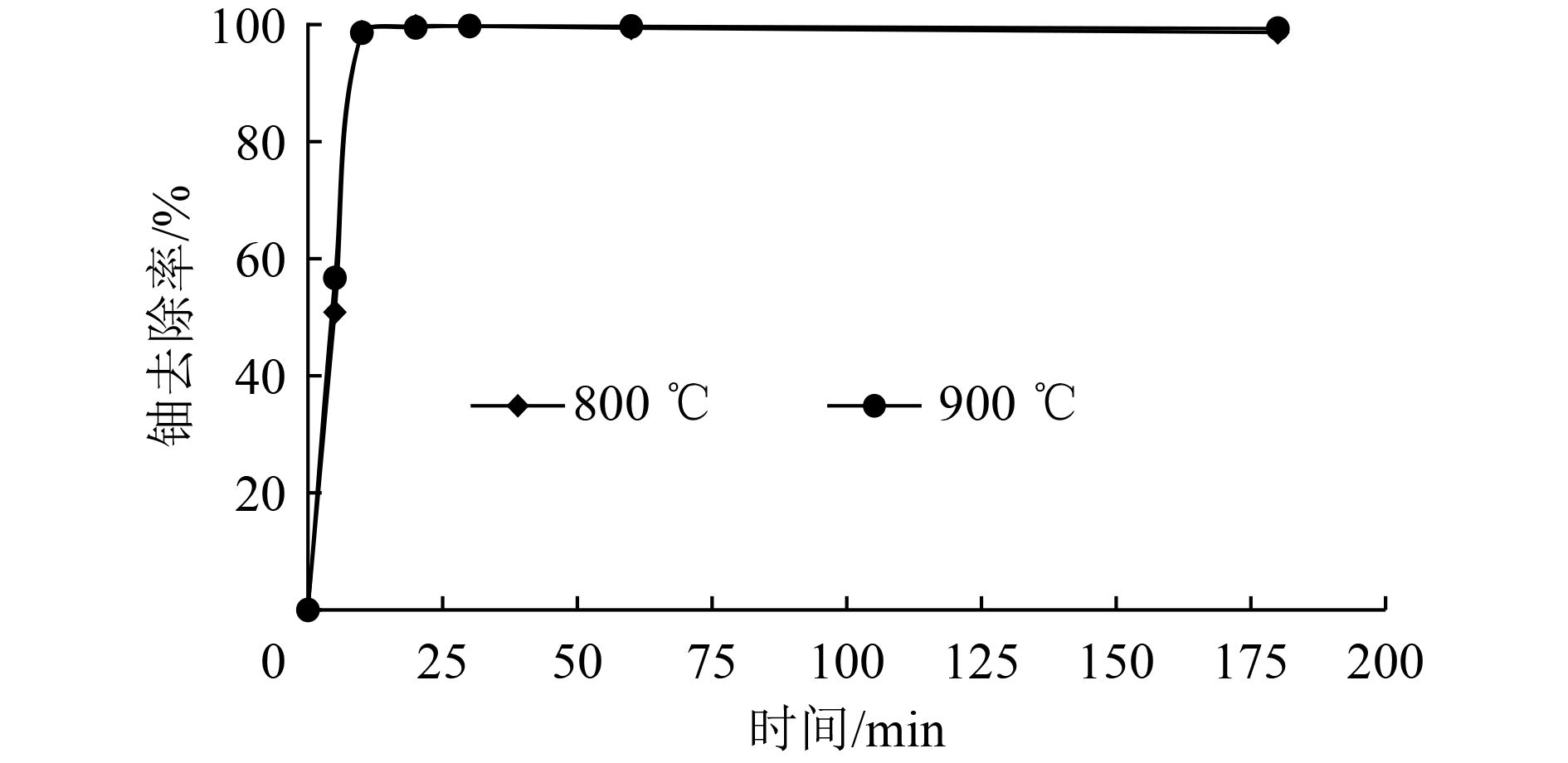

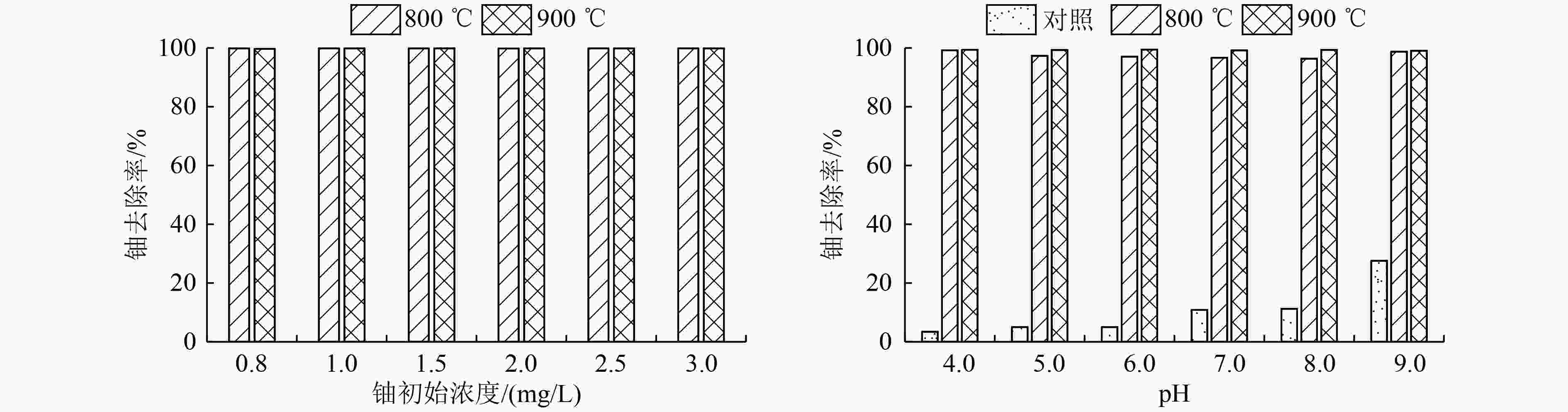

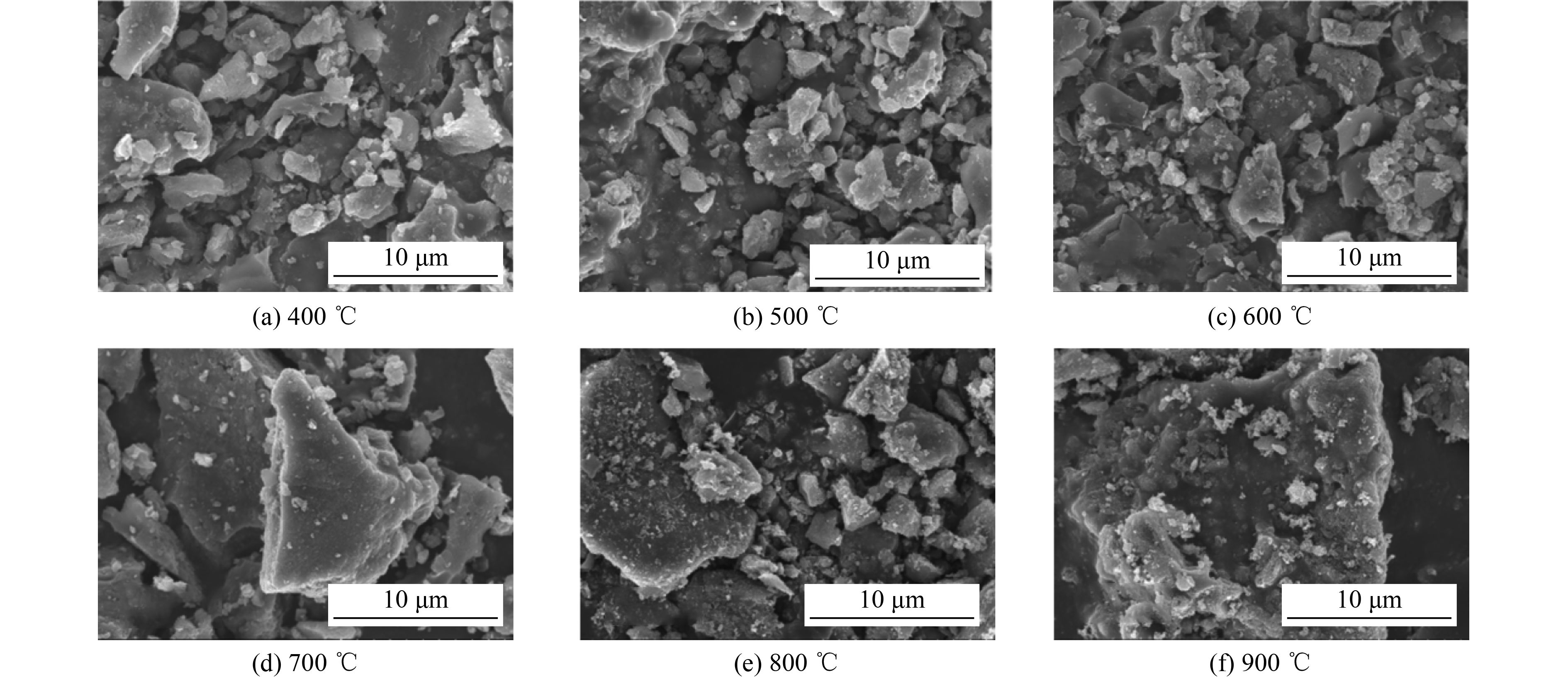

以土霉素菌渣(oxytetracycline fermentation residue,OFR)为原料,在300~900 ℃(间隔100 ℃)条件下制备生物炭,研究高温(800~900 ℃)制备OFR生物炭对废水中铀的吸附效果与机理。结果表明:对于不同温度下制备的生物炭,随着温度的升高,OFR生物炭表面功能基团逐渐减少,Ca晶体形态由CaC2O4(300~400 ℃)转变为CaCO3(500~700 ℃)、CaO(800~900 ℃),而这也导致了吸附效果的变化。当制备温度升至800~900 ℃时,OFR生物炭10 min吸附即可对南方某铀尾矿库渗排水中的铀达到98%以上去除率,且高温制备的OFR生物炭在较宽的pH范围(4.0~9.0)与铀初始浓度(0.8~3.0 mg/L)下,均能稳定达到大于98%的去除率,处理后上清液中铀浓度远低于铀矿冶辐射防护和辐射环境保护规定的排放标准。因此,高温制备OFR生物炭在铀尾矿库渗排水原位处理方面,展示了较好的应用前景。

Abstract:Oxytetracycline fermentation residues (OFR) were used to prepare biochar under different temperatures (from 300 to 900 ℃ with an interval of 100 ℃) for uranium adsorption and removal in the wastewater, and the adsorption efficiency and mechanism were studied. The results showed that as the rise of temperature, the surface function groups of OFR biochar, prepared at different temperatures, were decreased gradually and the crystal morphology of Ca was transformed from CaC2O4 (300-400 ℃) to CaCO3 (500-700 ℃) and CaO (800-900 ℃), which leaded to the changes of removal efficiency. When the temperature was raised to 800-900 ℃, the biochar adsorption achieved more than 98% removal efficiency of uranium in seepage of a tailing pond in the South of China in 10 min. Further studies found that more than 98% of uranium could be removed under the condition of wide range of pH (4.0-9.0) and initial uranium concentration (0.8-3.0 mg/L), and the supernatant after treated was much lower than the limit of discharge standard stipulated by radiation protection and radiation environment protection in uranium mining and metallurgy. Therefore, OFR biochar prepared at high temperature showed a good application prospect in in-situ treatment of uranium tailings drainage.

-

表 1 OFR与不同温度下制备的生物炭的元素含量和得率

Table 1. Element contents and yields of OFR biochar prepared at different temperatures

% 制备

温度/℃C N H S 灰分 Ca O 生物炭

得率OFR1) 39.92 6.03 4.07 0.217 13.67 0.88 36.09 300 48.32 8.05 4.00 0.51 16.83 1.34 20.95 53.78 400 49.90 6.48 3.20 0.24 21.84 1.60 16.74 50.44 500 52.84 6.49 2.86 0.23 27.15 2.13 8.30 43.73 600 51.99 4.85 1.84 0.306 29.47 1.78 9.77 44.17 700 53.57 3.39 1.29 0.36 31.67 2.38 7.35 42.49 800 56.16 2.64 1.12 0.47 34.97 2.53 2.12 39.04 900 56.94 1.63 0.76 0.41 34.76 3.34 2.17 39.13 1)为未碳化前的原始OFR。 表 2 OFR与不同温度下制备的生物炭的微孔结构

Table 2. Microporous structure of OFR biochar prepared at different temperatures

制备

温度/℃比表面积 /

(m²/g)微孔面积/

(m²/g)介孔面积/

(m²/g)总孔体积/

(cm³/g)平均微孔

孔径/nmOFR1) 2.235 6 0.4176 1.8180 0.002 75 2.559 2 300 2.655 5 1.223 9 1.431 6 0.010 04 7.733 2 400 2.805 7 1.743 6 1.062 1 0.005 05 3.717 1 500 21.363 6 8.499 0 12.864 6 0.016 02 3.309 7 600 24.774 2 11.342 0 13.432 2 0.017 11 3.312 4 700 30.487 5 18.793 3 11.694 2 0.017 82 3.241 3 800 39.426 2 26.210 3 13.215 9 0.018 64 3.179 2 900 40.026 3 25.810 9 14.215 4 0.018 53 3.232 8 1)为未碳化前的原始OFR。 表 3 原水理化指标检测结果

Table 3. Results of physical and chemical indexes in raw water

pH NH4 +-N/

(mg/L)COD/

(mg/L)Cl−/

(mg/L)NO3 −/

(g/L)Cd/

(μg/L)铀/

(μg/L)Fe/

(μg/L)Mg/

(mg/L)Zn/

(mg/L)5.8 21.6 6.53 359 6.04 38.5 820 107 122 1.29 -

[1] 章求才, 娄亚龙, 刘永, 等.某铀尾矿库渗水中铀的化学形态和影响因素模拟分析[J]. 工业安全与环保,2018,44(6):1-4. doi: 10.3969/j.issn.1001-425X.2018.06.001ZHANG Q C, LOU Y L, LIU Y, et al. Chemical species and influence factors analysis of uranium in the seepage of one uranium tailings pond[J]. Industrial Safety and Environmental Protection,2018,44(6):1-4. doi: 10.3969/j.issn.1001-425X.2018.06.001 [2] BERGMANN M, SOBRAL O, PRATAS J, et al. Uranium toxicity to aquatic invertebrates: a laboratory assay[J]. Environmental Pollution,2018,239:359-366. doi: 10.1016/j.envpol.2018.04.007 [3] 王宏洋, 王旭, 陈海燕, 等.尾矿库环境风险管控相关政策分析及建议[J]. 环境科学研究,2023,36(5):1052-1060.WANG H Y, WANG X, CHEN H Y, et al. Analysis and suggestions of environmental risk control strategy for tailings ponds[J]. Research of Environmental Sciences,2023,36(5):1052-1060. [4] TROYER L D, MAILLOT F, WANG Z M, et al. Effect of phosphate on U(Ⅵ) sorption to montmorillonite: ternary complexation and precipitation barriers[J]. Geochimica et Cosmochimica Acta,2016,175:86-99. doi: 10.1016/j.gca.2015.11.029 [5] ZOU Y D, LIU Y, WANG X X, et al. Glycerol-modified binary layered double hydroxide nanocomposites for uranium immobilization via extended X-ray absorption fine structure technique and density functional theory calculation[J]. ACS Sustainable Chemistry & Engineering,2017,5(4):3583-3595. [6] REGMI P, MOSCOSO J L G, KUMAR S, et al. Removal of copper and cadmium from aqueous solution using switchgrass biochar produced via hydrothermal carbonization process[J]. Journal of Environmental Management,2012,109:61-69. [7] INYANG M, GAO B, PULLAMMANAPPALLIL P, et al. Biochar from anaerobically digested sugarcane bagasse[J]. Bioresource Technology,2010,101(22):8868-8872. doi: 10.1016/j.biortech.2010.06.088 [8] ALAM M S, GORMAN-LEWIS D, CHEN N, et al. Mechanisms of the removal of U(Ⅵ) from aqueous solution using biochar: a combined spectroscopic and modeling approach[J]. Environmental Science & Technology,2018,52(22):13057-13067. [9] LI L, YANG M, LU Q, et al. Oxygen-rich biochar from torrefaction: a versatile adsorbent for water pollution control[J]. Bioresource Technology,2019,294:122142. doi: 10.1016/j.biortech.2019.122142 [10] DAI L C, LI L, ZHU W K, et al. Post-engineering of biochar via thermal air treatment for highly efficient promotion of uranium(Ⅵ) adsorption[J]. Bioresource Technology,2020,298:122576. doi: 10.1016/j.biortech.2019.122576 [11] ZHANG Z B, CAO X H, LIANG P, et al. Adsorption of uranium from aqueous solution using biochar produced by hydrothermal carbonization[J]. Journal of Radioanalytical and Nuclear Chemistry,2013,295(2):1201-1208. doi: 10.1007/s10967-012-2017-2 [12] KUMAR S, LOGANATHAN V A, GUPTA R B, et al. An assessment of U(Ⅵ) removal from groundwater using biochar produced from hydrothermal carbonization[J]. Journal of Environmental Management,2011,92(10):2504-2512. doi: 10.1016/j.jenvman.2011.05.013 [13] SUN Y B, YANG S B, CHEN Y E, et al. Adsorption and desorption of U(Ⅵ) on functionalized graphene oxides: a combined experimental and theoretical study[J]. Environmental Science & Technology,2015,49(7):4255-4262. [14] CAO X D, MA L N, GAO B, et al. Dairy-manure derived biochar effectively sorbs lead and atrazine[J]. Environmental Science & Technology,2009,43(9):3285-3291. [15] ALAM M S, COSSIO M, ROBINSON L, et al. Removal of organic acids from water using biochar and petroleum coke[J]. Environmental Technology & Innovation,2016,6:141-151. [16] UCHIMIYA M, CHANG S, KLASSON K T. Screening biochars for heavy metal retention in soil: role of oxygen functional groups[J]. Journal of Hazardous Materials,2011,190(1/2/3):432-441. [17] JIN J, LI S W, PENG X Q, et al. HNO3 modified biochars for uranium (Ⅵ) removal from aqueous solution[J]. Bioresource Technology,2018,256:247-253. doi: 10.1016/j.biortech.2018.02.022 [18] SUN Y B, WU Z Y, WANG X X, et al. Macroscopic and microscopic investigation of U(Ⅵ) and Eu(Ⅲ) adsorption on carbonaceous nanofibers[J]. Environmental Science & Technology,2016,50(8):4459-4467. [19] 王娟, 郭亚丹, 曾华, 等.羟基磷灰石复合材料对地下水中铀吸附去除研究进展[J]. 有色金属(冶炼部分),2021(8):37-45.WANG J, GUO Y D, ZENG H, et al. Progress of hydroxyapatite composites for adsorption and removal of uranium from groundwater[J]. Nonferrous Metals (Extractive Metallurgy),2021(8):37-45. [20] 秦坤, 李佳乐, 王章鸿, 等.富Ca香菇菌渣基生物炭对含磷废水处理性能的研究[J]. 化工学报,2022,73(11):5263-5274.QIN K, LI J L, WANG Z H, et al. Biochars derived from Ca-rich mushroom residue for phosphorus-containing wastewater treatment[J]. CIESC Journal,2022,73(11):5263-5274. [21] 王胜丹. 负载钙生物炭回收水中磷酸盐及其产物对铀(Ⅵ)固定的特性研究[D]. 广州: 广州大学, 2018. [22] YING G G, HE L Y, YING A J, et al. China must reduce its antibiotic use[J]. Environmental Science & Technology,2017,51(3):1072-1073. [23] 姚光远, 刘玉强, 刘景财, 等.我国医药制造业危险废物产生特性及污染防治分析[J]. 环境工程技术学报,2021,11(6):1258-1265.YAO G Y, LIU Y Q, LIU J C, et al. Research on the generation properties and pollution control of pharmaceutical manufacturing industry in China[J]. Journal of Environmental Engineering Technology,2021,11(6):1258-1265. [24] 彭燕, 陈迪云, 陈南, 等.磷酸钙对铀矿下游水系沉积物中铀的钝化效果[J]. 环境工程,2021,39(4):13-19. doi: 10.13205/j.hjgc.202104003PENG Y, CHEN D Y, CHEN N, et al. Passivation effect of calcium phosphate on uranium in sediments in downstream waters of a uranium mine[J]. Environmental Engineering,2021,39(4):13-19. doi: 10.13205/j.hjgc.202104003 [25] 林升, 付映文, 那兵, 等.磷酸氢钙原位矿化铀酰离子性能及机制研究[J]. 东华理工大学学报(自然科学版),2022,45(3):275-281.LIN S, FU Y W, NA B, et al. Property and mechanism of in situ mineralization of uranyl ions with calcium hydrogen phosphate[J]. Journal of East China University of Technology (Natural Science),2022,45(3):275-281. [26] 环境保护部. 水质 65种元素的测定 电感耦合等离子体质谱法: HJ 700—2014[S]. 北京: 中国环境科学出版社, 2014. [27] 卫生部, 国家标准化管理委员会. 生活饮用水标准检验方法 无机非金属指标: GB/T 5750.5—2006[S]. 北京: 中国标准出版社, 2007. [28] 王晖, 郭霄, 马翔, 等.模拟酸雨对耐冬山茶生理生态学特征的影响[J]. 青岛农业大学学报(自然科学版),2022,39(1):43-50.WANG H, GUO X, MA X, et al. Effects of simulated acid rain on the ecophysiological characteristics of Camellia japonica (NaiDong)[J]. Journal of Qingdao Agricultural University (Natural Science),2022,39(1):43-50. [29] LU Q, DAI L C, LI L, et al. Valorization of oxytetracycline fermentation residue through torrefaction into a versatile and recyclable adsorbent for water pollution control[J]. Journal of Environmental Chemical Engineering,2021,9(4):105397. doi: 10.1016/j.jece.2021.105397 [30] CHEN B L, CHEN Z M. Sorption of naphthalene and 1-naphthol by biochars of orange peels with different pyrolytic temperatures[J]. Chemosphere,2009,76(1):127-133. doi: 10.1016/j.chemosphere.2009.02.004 [31] 生态环境部, 国家市场监督管理总局. 铀矿冶辐射防护和辐射环境保护规定: GB 23727—2020[S]. 北京: 中国环境科学出版社, 2020. -

下载:

下载: