Spray pyrolysis technology and its application in environmental pollution control

-

摘要:

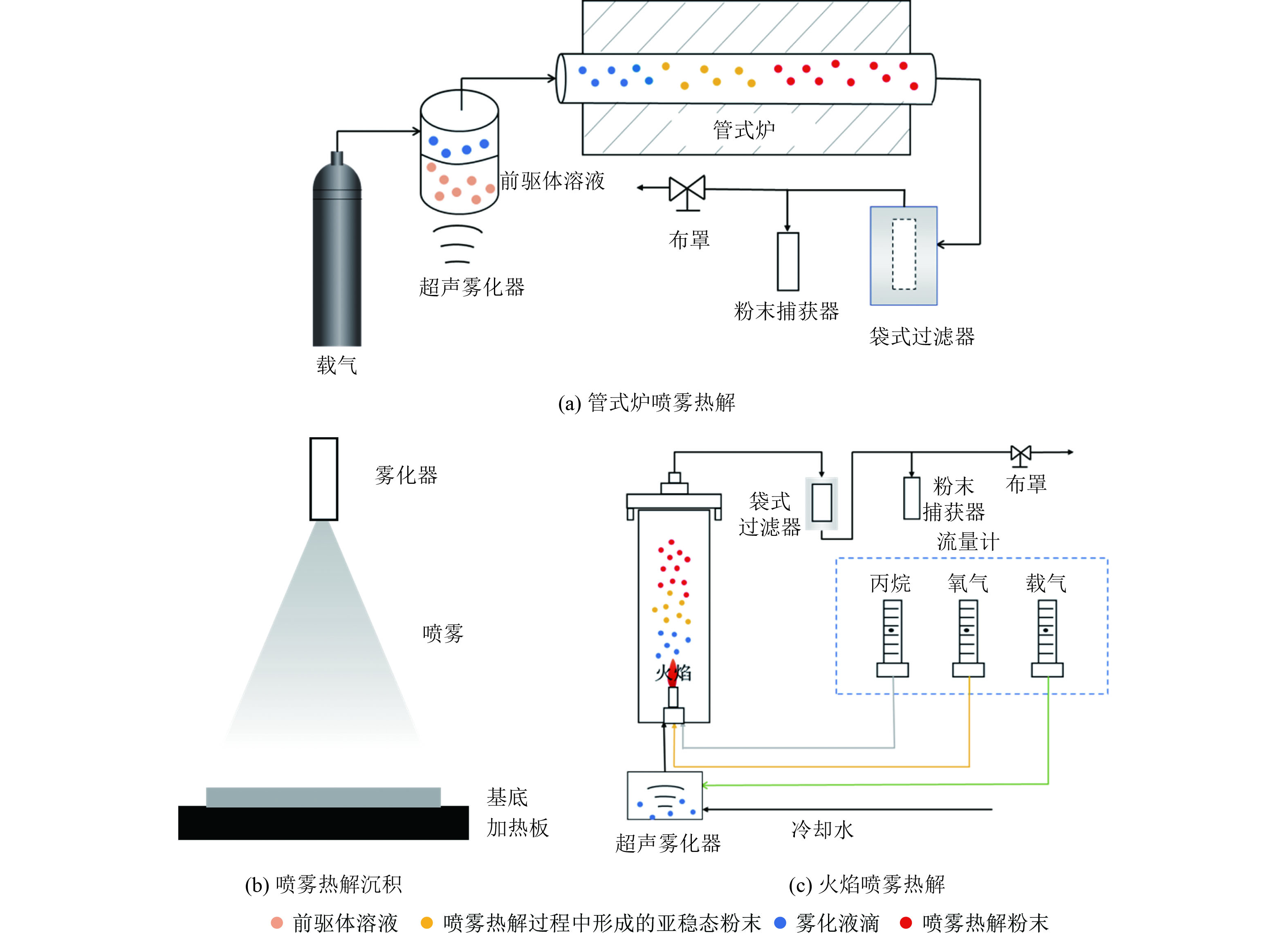

喷雾热解作为一种一步完成、连续、拓展性强、可大规模制备环境功能纳米材料的新型热解技术受到研究者的广泛关注。详细介绍了喷雾热解技术的工作原理、产物特性、环境应用以及工业化推广面临的挑战,并可视化分析了喷雾热解技术在环境污染控制领域的研究热点。结果表明:喷雾热解是通过高温下分解前驱体溶液制备纳米颗粒的技术,其设备主要由雾化器、加热设备和收集装置组成。喷雾热解的产物特性受到前驱体溶液和热解过程参数的影响,通过调控前驱体的溶液组分和热解过程参数,可以得到尺寸和形貌可控的特定环境功能纳米材料。喷雾热解技术制备的环境功能纳米材料(如粉末或薄膜)的应用研究表明,由于其特殊的物化结构,可实现大气和水体中污染物的高效去除。同时,基于研究热点分析了喷雾热解技术的热解方式、产物特性、应用领域和去除污染物的主要机理。但目前喷雾热解技术从实验室规模拓展到工业化应用还面临着诸多挑战,如何克服这些挑战也是喷雾热解技术走向工业化应用的重要内容。研究可为喷雾热解技术在环境污染控制领域的应用提供理论和技术支撑。

Abstract:Spray pyrolysis, as a new pyrolysis technology for one-step, continuous, highly expandable, and large-scale preparation of environmental functional nanomaterials, has received the attention of researchers. The working principles, product characteristics, environmental applications and industrial challenges of spray pyrolysis technology were introduced in detail, and the hot spots of spray pyrolysis technology in the field of environmental pollution control were visually analyzed. The results show that spray pyrolysis is a technology for producing nanoparticles by decomposing precursor solutions at high temperature and its equipment mainly consists of atomizer, heating equipment and collection device. The product property of spray pyrolysis is influenced by precursor solution and pyrolysis parameters. By controlling precursor solution composition and pyrolysis process parameters, nanomaterials with desirable size and morphology can be obtained. Owing to the specific physicochemical properties, these environmental functional nanomaterials (e.g., powders or thin films) prepared by spray pyrolysis technology are highly effective for the removal of pollutants from both atmosphere and wastewater. Simultaneous, based on the research focus, the pyrolysis method, product characteristics, application fields and the main mechanism of pollutant removal of spray pyrolysis technology were analyzed. However, there are still many challenges in expanding the spray pyrolysis technology from laboratory scale to industrial application. The research can provide theoretical and technical support for the application of spray pyrolysis technology in the field of environmental pollution control.

-

表 1 喷雾热解技术合成环境纳米材料的应用案例

Table 1. Application cases of spray pyrolysis technology to synthesize environmental nanomaterials

环境污染控制领域 环境纳米材料 形貌 喷雾热解技术 目标污染物 去除原理 大气 PbWO4[19] 实心球或空心球粉末 管式炉 NO 光催化 N掺杂的MOx-ZnO(M为W、V)[20] 中空球形粉末 管式炉 乙醛 光催化 N掺杂的TiO2[21] 多孔球形粉末 管式炉 乙醛 光催化 TiO2[22] 多孔球形粉末 管式炉 NOx 光催化 水处理 黑色TiO2-x[23] 微球粉末 管式炉 亚甲基蓝 光催化 Fe2O3-Al2O3[24] 空心球状粉末 管式炉 多环芳烃 吸附 ZnO或ZnO:Al[25] 薄膜 热解沉积 甲基橙 光催化 ZnO或ZnO:Al[26] 薄膜 热解沉积 硬脂酸 光催化 ZnO[27] 薄膜 热解沉积 甲基橙 光催化 La2O3:Fe[28] 薄膜 热解沉积 亚甲基蓝 光催化 CeO2-金红石TiO2[29] 薄膜 热解沉积 甲基橙 光催化 Au负载ZnO[30] 粉末 管式炉 罗丹明B 光催化 CuxO[31] 薄膜 热解沉积 亚甲基蓝 光催化 ZnO/Al2O3[32] 薄膜 热解沉积 亚甲基蓝 光催化 Cu2SnS3[33] 薄膜 热解沉积 亚甲基蓝 光催化 In2S3:Ag[34] 薄膜 热解沉积 亚甲基蓝 光催化 La2O3/LaFeO3[35] 薄膜 热解沉积 亚甲基蓝 光催化 TiO2[36] 微球 管式炉 对乙酰氨基酚 光催化 CuAl2O4[37] 薄膜 管式炉 亚甲基蓝 光催化 TiO2[38] 粉末 火焰喷雾热解 亚甲基蓝 光催化 ZnO[39] 薄膜 热解沉积 甲基橙 光催化 TiO2[40] 薄膜 热解沉积 甲基叔丁基醚、丙酮、乙醛、庚烷 光催化 BiVO4[41] 薄膜 热解沉积 罗丹明B、甲基橙 光催化 ZnO-SiO2[42] 类球形粉末 管式炉 亚甲基蓝 光催化 Cu2FeSnS4[43] 薄膜 热解沉积 亚甲基蓝 光催化 Tb掺杂的SnO2[44] 薄膜 热解沉积 亚甲基蓝 光催化 ZnO[45] 薄膜 热解沉积 亚甲基蓝 光催化 Cu掺杂的ZnO[46] 薄膜 热解沉积 亚甲基蓝 光催化 -

[1] CHOI S H, KANG Y C. Fe3O4-decorated hollow graphene balls prepared by spray pyrolysis process for ultrafast and long cycle-life lithium ion batteries[J]. Carbon,2014,79:58-66. doi: 10.1016/j.carbon.2014.07.042 [2] LENG J, WANG Z X, WANG J X, et al. Advances in nanostructures fabricated via spray pyrolysis and their applications in energy storage and conversion[J]. Chemical Society Reviews,2019,48(11):3015-3072. doi: 10.1039/C8CS00904J [3] SAWANT J P, DEOKATE R J, PATHAN H M, et al. Spray pyrolytic deposition of CuInS2 thin films: properties and applications[J]. Engineered Science,2021,13:51-64. [4] ZHU Y J, CHOI S H, FAN X L, et al. Recent progress on spray pyrolysis for high performance electrode materials in lithium and sodium rechargeable batteries[J]. Advanced Energy Materials,2017,7(7):1601578. doi: 10.1002/aenm.201601578 [5] NIE P, XU G Y, JIANG J M, et al. Aerosol-spray pyrolysis toward preparation of nanostructured materials for batteries and supercapacitors[J]. Small Methods,2018,2(2):1700272. doi: 10.1002/smtd.201700272 [6] PARK J S, KIM J K, HONG J H, et al. Advances in the synthesis and design of nanostructured materials by aerosol spray processes for efficient energy storage[J]. Nanoscale,2019,11(41):19012-19057. doi: 10.1039/C9NR05575D [7] VIJAYAN K, VIJAYACHAMUNDEESWARI S P, SIVAPERUMAN K. A review on advancements, challenges, and prospective of copper and non-copper based thin-film solar cells using facile spray pyrolysis technique[J]. Solar Energy,2022,234:81-102. doi: 10.1016/j.solener.2022.01.070 [8] SRIRAM S R, PARNE S R, POTHUKANURI N. Prospects of spray pyrolysis technique for gas sensor applications: a comprehensive review[J]. Journal of Analytical and Applied Pyrolysis,2022,164:105527. doi: 10.1016/j.jaap.2022.105527 [9] JUNG D S, BIN PARK S, KANG Y C. Design of particles by spray pyrolysis and recent progress in its application[J]. Korean Journal of Chemical Engineering,2010,27(6):1621-1645. doi: 10.1007/s11814-010-0402-5 [10] WOOD R W, LOOMIS A L. The physical and biological effects of high-frequency sound-waves of great intensity[J]. The London, Edinburgh, and Dublin Philosophical Magazine and Journal of Science,1927,4(22):417-436. doi: 10.1080/14786440908564348 [11] BANG J H, SUSLICK K S. Applications of ultrasound to the synthesis of nanostructured materials[J]. Advanced Materials (Deerfield Beach, Fla),2010,22(10):0904093. [12] LANG R J. Ultrasonic atomization of liquids[J]. The Journal of the Acoustical Society of America,1962,34(1):6-8. doi: 10.1121/1.1909020 [13] MOTL N E, MANN A K P, SKRABALAK S E. Aerosol-assisted synthesis and assembly of nanoscale building blocks[J]. Journal of Materials Chemistry A,2013,1(17):5193. doi: 10.1039/c3ta01703f [14] 王世凯, 姜妍彦, 唐乃岭, 等.超声喷雾热解法制备半导体薄膜技术[J]. 材料导报,2011,25(13):70-74.WANG S K, JIANG Y Y, TANG N L, et al. Ultrasonic spray pyrolysis technology for deposition of semiconductor thin films[J]. Materials Review,2011,25(13):70-74. [15] SALISBURY C L, TUNCEL G, ONDOV J M. Ultrafine particle generation at high liquid flow rates with commercial two-fluid nozzles[J]. Aerosol Science and Technology,1991,15(3):156-169. doi: 10.1080/02786829108959522 [16] NANDIYANTO A B D, OKUYAMA K. Progress in developing spray-drying methods for the production of controlled morphology particles: from the nanometer to submicrometer size ranges[J]. Advanced Powder Technology,2011,22(1):1-19. doi: 10.1016/j.apt.2010.09.011 [17] CHOI S H, KO Y N, LEE J K, et al. 3D MoS2-graphene microspheres consisting of multiple nanospheres with superior sodium ion storage properties[J]. Advanced Functional Materials,2015,25(12):1780-1788. doi: 10.1002/adfm.201402428 [18] HONG Y J, KANG Y C. One-pot synthesis of core-shell-structured tin oxide-carbon composite powders by spray pyrolysis for use as anode materials in Li-ion batteries[J]. Carbon,2015,88:262-269. doi: 10.1016/j.carbon.2015.03.010 [19] DONG F, HUANG Y, ZOU S C, et al. Ultrasonic spray pyrolysis fabrication of solid and hollow PbWO4 spheres with structure-directed photocatalytic activity[J]. The Journal of Physical Chemistry C,2011,115(1):241-247. doi: 10.1021/jp108221v [20] LI D, HANEDA H. Enhancement of photocatalytic activity of sprayed nitrogen-containing ZnO powders by coupling with metal oxides during the acetaldehyde decomposition[J]. Chemosphere,2004,54(8):1099-1110. doi: 10.1016/j.chemosphere.2003.09.022 [21] LI D, HANEDA H, HISHITA S, et al. Visible-light-active nitrogen-containing TiO2 photocatalysts prepared by spray pyrolysis[J]. Research on Chemical Intermediates,2005,31(4/5/6):331-341. [22] NALDONI A, BIANCHI C L, PIROLA C, et al. Porous TiO2 microspheres with tunable properties for photocatalytic air purification[J]. Ultrasonics Sonochemistry, 2013, 20(1): 445-451. [23] JI M, CHOA Y, LEE Y. One-step synthesis of black TiO2-x microspheres by ultrasonic spray pyrolysis process and their visible-light-driven photocatalytic activities[J]. Ultrasonics Sonochemistry,2021,74:105557. doi: 10.1016/j.ultsonch.2021.105557 [24] VOJOUDI H, GHASEMI J B, HAJIHOSSEINLOO A. One-pot synthesis of hematite-alumina hollow sphere composite by ultrasonic spray pyrolysis technique with high adsorption capacity toward PAHs[J]. Advanced Powder Technology,2021,32(4):1060-1069. doi: 10.1016/j.apt.2021.02.015 [25] BIZARRO M. High photocatalytic activity of ZnO and ZnO:Al nanostructured films deposited by spray pyrolysis[J]. Applied Catalysis B:Environmental,2010,97(1/2):198-203. [26] KENANAKIS G, KATSARAKIS N. Ultrasonic spray pyrolysis growth of ZnO and ZnO:Al nanostructured films: application to photocatalysis[J]. Materials Research Bulletin,2014,60:752-759. doi: 10.1016/j.materresbull.2014.09.060 [27] DUTA M, PERNIU D, DUTA A. Photocatalytic zinc oxide thin films obtained by surfactant assisted spray pyrolysis deposition[J]. Applied Surface Science,2014,306:80-88. doi: 10.1016/j.apsusc.2014.02.132 [28] JBELI R, BOUKHACHEM A, SAADALLAH F, et al. Synthesis and physical properties of Fe doped La2O3 thin films grown by spray pyrolysis for photocatalytic applications[J]. Materials Research Express, 2019, 6: 066414. [29] RADIĆ N,GRBIĆ B,PETROVIĆ S, et al. Effect of cerium oxide doping on the photocatalytic properties of rutile TiO2 films prepared by spray pyrolysis[J]. Physica B: Condensed Matter, 2020, 599: 412544. [30] LEE Y, FUJIMOTO T, YAMANAKA S, et al. Evaluation of photocatalysis of Au supported ZnO prepared by the spray pyrolysis method[J]. Advanced Powder Technology,2021,32(5):1619-1626. doi: 10.1016/j.apt.2021.03.025 [31] MADKOUR M. CuxO thin films via ultrasonic spray pyrolysis as efficient solar photocatalysts: single source polymeric coordinated precursor[J]. Colloid and Interface Science Communications,2021,44:100497. doi: 10.1016/j.colcom.2021.100497 [32] POLAT GONULLU M. Design and characterization of single bilayer ZnO/Al2O3 film by ultrasonically spray pyrolysis and its application in photocatalysis[J]. Micro and Nanostructures,2022,164:107113. doi: 10.1016/j.spmi.2021.107113 [33] RAHAMAN S, SINGHA M K. Nanoarchitectonics earth-abundant chalcogenide Cu2SnS3 thin film using ultrasonic spray pyrolysis for visible light-driven photocatalysis[J]. Applied Physics A,2022,128(1):36. doi: 10.1007/s00339-021-05174-5 [34] TISS B, BENFRAJ M, BOUGUILAN, et al. The effect of vacuum and air annealing in the physical characteristics and photocatalytic efficiency of In2S3:Ag thin films produced by spray pyrolysis[J]. Materials Chemistry and Physics,2021,270:124838. doi: 10.1016/j.matchemphys.2021.124838 [35] BILEL C. Investigation on the photocatalytic activity of La2O3/LaFeO3 composite prepared by spray pyrolysis technique[J]. Journal of Materials Science:Materials in Electronics,2022,33(10):8209-8217. doi: 10.1007/s10854-022-07971-x [36] da SILVA A L, TRINDADE F J, DALMASSLO J L, et al. Synthesis of TiO2 microspheres by ultrasonic spray pyrolysis and photocatalytic activity evaluation[J]. Ceramics International,2022,48(7):9739-9745. doi: 10.1016/j.ceramint.2021.12.175 [37] SUHARIADI I, RAHMAWAN Y, MUYASSIROH D A M, et al. Low-temperature deposition of CuAl2O4 thin film photocatalyst by ultrasonic spray pyrolysis[J]. Materials Letters,2022,311:131620. doi: 10.1016/j.matlet.2021.131620 [38] BETTINI L G, DIAMANTI M V, SANSOTERA M, et al. Immobilized TiO2 nanoparticles produced by flame spray for photocatalytic water remediation[J]. Journal of Nanoparticle Research,2016,18(8):238. doi: 10.1007/s11051-016-3551-6 [39] PORTILLO-VÉLEZ N S, BIZARRO M. Sprayed pyrolyzed ZnO films with nanoflake and nanorod morphologies and their photocatalytic activity[J]. Journal of Nanomaterials,2016,2016:1-11. [40] DUNDAR I, KRICHEVSKAYA M, KATERSKI A, et al. Photocatalytic degradation of different VOCs in the gas-phase over TiO2 thin films prepared by ultrasonic spray pyrolysis[J]. Catalysts,2019,9(11):915. doi: 10.3390/catal9110915 [41] ARIVUKARASAN D, DHAS C R, VENKATESH R, et al. Template-free and cost-effective nebulizer spray-coated BiVO4 nanostructured thin films for photocatalytic applications[J]. Applied Physics A,2020,126(2):86. doi: 10.1007/s00339-019-3261-x [42] KUSDIANTO K, WIDIYASTUTI W, SHIMADA M, et al. Fabrication of ZnO-SiO2 nanocomposite materials prepared by a spray pyrolysis for the photocatalytic activity under UV and sunlight irradiations[J]. IOP Conference Series Materials Science and Engineering,2020,778(1):012105. doi: 10.1088/1757-899X/778/1/012105 [43] NEFZI C, SOULI M, CUMINAL Y, et al. Effect of substrate temperature on physical properties of Cu2FeSnS4 thin films for photocatalysis applications[J]. Materials Science and Engineering:B,2020,254:114509. doi: 10.1016/j.mseb.2020.114509 [44] RAJ I L P, REVATHY M S, CHRISTY A J, et al. Study on the synergistic effect of terbium-doped SnO2 thin film photocatalysts for dye degradation[J]. Journal of Nanoparticle Research,2020,22(12):359. doi: 10.1007/s11051-020-05084-2 [45] SINGHA M K, PATRA A, ROJWAL V, et al. Single-step fabrication of ZnO microflower thin films for highly efficient and reusable photocatalytic activity[J]. Journal of Materials Science:Materials in Electronics,2020,31(16):13578-13587. doi: 10.1007/s10854-020-03914-6 [46] KARTHIK T K, MALDONADO A, OLVERA M D L L, et al. Copper-doped ZnO thin films deposited by spray pyrolysis: effect of water content in starting solution on methylene blue degradation by photocatalysis[J]. Journal of Electronic Materials,2021,50(10):5542-5552. doi: 10.1007/s11664-021-09088-z [47] KHOJIER K. Investigation of ZnO thin film synthesized by spray pyrolysis method as a toxic gases sensor[J]. Journal of Electronic Materials,2017,46(10):5889-5894. doi: 10.1007/s11664-017-5583-9 [48] DUNDAR I, KRICHEVSKAYA M, KATERSKI A, et al. TiO2 thin films by ultrasonic spray pyrolysis as photocatalytic material for air purification[J]. Royal Society Open Science,2019,6(2):181578. doi: 10.1098/rsos.181578 [49] CUI Y, ATKINSON J D. Ultrasonic spray pyrolysis synthesis of nitrogen-doped porous Fe/C composites from glycerol for hexavalent chromium removal[J]. Materials Chemistry and Physics,2019,221:29-33. ◇ -

下载:

下载: