Passivation effect of Fe0 in the removal of Cr (Ⅵ) from groundwater and the optimization of electrochemical depassivation parameters

-

摘要:

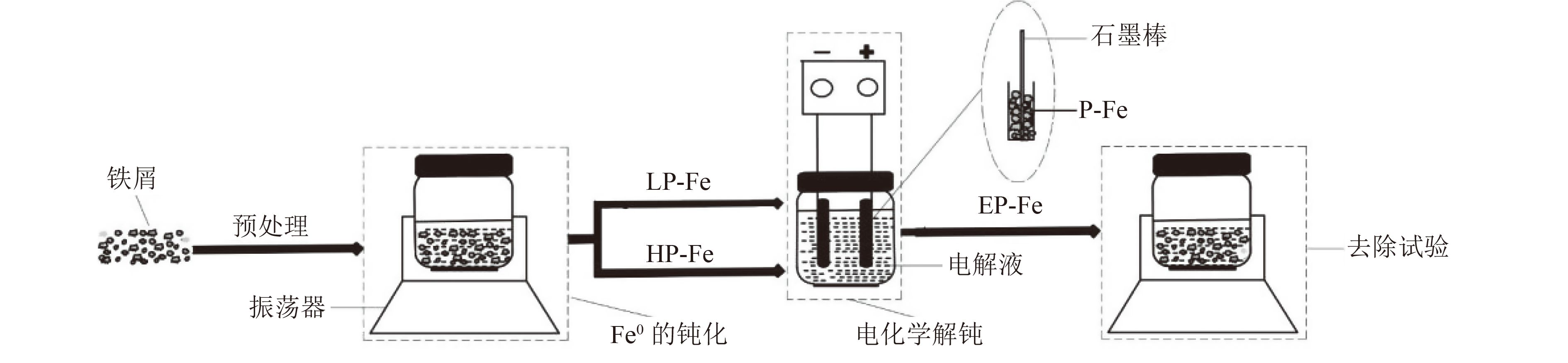

零价铁(Fe0)广泛用于Cr(Ⅵ)污染地下水的修复,但存在Fe0钝化降低修复效率的问题。首先使用Fe0去除地下水中的Cr(Ⅵ)并制备不同钝化程度的钝化铁屑,然后采用电化学方法对钝化铁屑进行解钝,并通过单因素试验和正交试验研究电极设置、电解电压、电解时间及电极距对解钝效果的影响,同时对解钝溶液和解钝前后的铁屑及解钝过程中产生的沉淀进行分析。结果表明:以钝化铁屑作阳极时解钝效果最佳;解钝效果随电解电压增大先上升后降低,随电极距增大而降低,随电解时间增加而上升,3个因素对解钝效果的影响依次为电解时间>电解电压>电极距;X射线衍射仪、扫描电子显微镜和能谱分析表明,钝化铁屑在电化学作用下因表面沉淀脱落使得其活性得到有效恢复;钝化铁屑解钝的最佳条件(以钝化铁屑作阳极,电解电压为10 V,电解时间为60 min,电极距为2 cm)下,解钝后铁屑对Cr(Ⅵ)的去除率可恢复至原来的90%以上;解钝过程中不会促使Cr(Ⅲ)沉淀溶解,但会增加溶液中Fe的浓度。上述研究成果对提高Fe0修复Cr(Ⅵ)污染地下水的修复效果及材料使用率具有参考作用。

-

关键词:

- 地下水修复 /

- 零价铁(Fe0) /

- 六价铬〔Cr(Ⅵ)〕 /

- 钝化 /

- 电化学解钝

Abstract:Zero-valent iron (Fe0) is widely used in the remediation of groundwater polluted by Cr(Ⅵ). However, there is a problem that passivation reduces the remediation efficiency. First of all, Fe0 was used to remove Cr (Ⅵ) in groundwater, and passivated iron filings with different passivation degrees were prepared. Subsequently, the electrochemical method was used to deactivate the passivated iron filings, and the effects of electrode setting, electrolysis voltage, electrolysis time and electrode distance on the depassivation effect were studied by single factor test and orthogonal test. Meanwhile, the depassivation solution and the iron filings before and after depassivation as well as the precipitate produced during the depassivation process were analyzed. The results showed that the depassivation effect was the best when passivated iron filings were used as anode. The depassivation effect first increased and then decreased with the increase of electrolysis voltage, decreased with the increase of electrode distance, and increased with the increase of electrolysis time. The influence of three factors on the depassivation effect from high to low was as follows: electrolysis time > electrolysis voltage > electrode distance. The results of the X-ray diffractometer, scanning electron microscope and energy dispersive spectroscopy analysis showed that the activity of passivated iron filings could be recovered effectively due to surface precipitation shedding under electrochemical action. The optimum conditions for depassivation of passivated iron filings were as follows: passivated iron filings for anode, electrolysis voltage = 10 V, electrolysis time = 60 min, electrode distance = 2 cm. Under these conditions, the removal rate of Cr (Ⅵ) by iron filings after depassivation could be restored to more than 90% of the original; Cr (Ⅲ) precipitate could not be dissolved, but the concentration of Fe in the solution could be increased during depassivation process. These research results could provide a useful reference for improving the remediation effect and material utilization rate of Cr (Ⅵ) polluted groundwater by Fe0.

-

表 1 电极影响试验分组

Table 1. Experimental grouping of electrode influence

组别 其他参数 P-Fe作为阳极,石墨

作为阴极电解电压为10 V,电极距为2 cm,电解时间为10 min,

在0.8 g/L的Na2SO4电解质

溶液中进行电化学解钝P-Fe作为阴极,石墨

作为阳极P-Fe作为阴阳极

(交叉电极)表 2 正交试验因素水平

Table 2. Factor level table of orthogonal test

水平 电解电压/V 电极距/cm 电解时间/min 1 5 2 10 2 10 4 30 3 20 6 60 表 3 正交试验设计及结果

Table 3. Orthogonal test design and result table

编号 A B C Cr(Ⅵ)去除率/% 1 1 1 1 55.5 2 1 2 2 63.2 3 1 3 3 70.4 4 2 1 2 85.2 5 2 2 3 88.1 6 2 3 1 62.3 7 3 1 3 76.4 8 3 2 1 58.2 9 3 3 2 73.4 水平1均值 63.0 72.4 58.6 水平2均值 78.5 69.8 73.9 水平3均值 69.3 68.7 78.3 极差 15.5 3.7 19.7 表 4 方差分析结果

Table 4. Results of variance analysis

方差来源 偏差平方和 自由度 F F临界值 P 电解电压 364.6 2 11.50 6.9 <0.05 电极距 21.1 2 0.69 6.9 电解时间 637.6 2 20.10 6.9 <0.05 误差 63.3 4 -

[1] FU F L, MA J, XIE L P, et al. Chromium removal using resin supported nanoscale zero-valent iron[J]. Journal of Environmental Management,2013,128:822-827. doi: 10.1016/j.jenvman.2013.06.044 [2] 徐腾, 南丰, 蒋晓锋, 等.制革场地土壤和地下水中铬污染来源及污染特征研究进展[J]. 土壤学报,2020,57(6):1341-1352.XU T, NAN F, JIANG X F, et al. Progresses in research on sources and characteristics of chromium pollution in soils and groundwater of tannery sites[J]. Acta Pedologica Sinica,2020,57(6):1341-1352. [3] 潘虹, 王兴润, 王雷, 等.生物炭负载硫化改性纳米零价铁去除水中的Cr(Ⅵ)[J]. 环境工程技术学报,2023,13(2):663-668.PAN H, WANG X R, WANG L, et al. Experimental study on the removal of Cr(Ⅵ) from water by biochar-based sulfide modification loaded with nano-zero valent iron[J]. Journal of Environmental Engineering Technology,2023,13(2):663-668. [4] GAO Y, XIA J. Chromium contamination accident in China: viewing environment policy of China[J]. Environmental Science & Technology,2011,45(20):8605-8606. [5] 张雨婷. 生物质炭对电镀废水中六价铬的去除及机理研究[D]. 长春: 吉林大学, 2020. [6] 陈明, 孙宗健, 王金生.加强环境监管 确保环境安全: 多起异地非法倾倒危险废物事件的启示[J]. 环境保护,2011,39(21):52-54. [7] 2018中国生态环境状况公报[R]. 北京:生态环境部, 2018. [8] 党伟, 王莉莉, 张婷婷.氨化酒糟吸附剂去除电镀废水中六价铬研究[J]. 环境工程技术学报,2020,10(1):79-84. doi: 10.12153/j.issn.1674-991X.20190083DANG W, WANG L L, ZHANG T T. Removal of hexavalent chromium from electroplating wastewater by ammoniated distilled grain-based adsorbent[J]. Journal of Environmental Engineering Technology,2020,10(1):79-84. doi: 10.12153/j.issn.1674-991X.20190083 [9] 孙艳涛, 刘适博, 李婷婷, 等.水中铬处理方法的研究进展[J]. 当代化工,2015,44(6):1368-1370.SUN Y T, LIU S B, LI T T, et al. Research progress in treating chromium in water[J]. Contemporary Chemical Industry,2015,44(6):1368-1370. [10] 卜芳, 郭建维, 王琴, 等.电沉积零价铁中性条件下还原去除Cr(Ⅵ)[J]. 化工进展,2011,30(增刊 1):870-873.BU F, GUO J W, WANG Q, et al. Reduction and removal of Cr(Ⅵ) by electrodeposition of zero-valent iron under neutral conditions[J]. Chemical Industry and Engineering Progress,2011,30(Suppl 1):870-873. [11] 刘翔, 唐翠梅, 陆兆华, 等.零价铁PRB技术在地下水原位修复中的研究进展[J]. 环境科学研究,2013,26(12):1309-1315.LIU X, TANG C M, LU Z H, et al. Progress of Fe0-PRB in remediation of contaminated groundwater[J]. Research of Environmental Sciences,2013,26(12):1309-1315. [12] 万龙, 孟凡生, 杨琦, 等.微电流对零价铁还原Cr(Ⅵ)过程中去钝化作用研究[J]. 环境工程技术学报,2018,8(4):429-434.WAN L, MENG F S, YANG Q, et al. Depassivation of micro current in hexavalent chromium reduction by zero valent iron[J]. Journal of Environmental Engineering Technology,2018,8(4):429-434. [13] HAN W J, FU F L, CHENG Z H, et al. Studies on the optimum conditions using acid-washed zero-valent iron/aluminum mixtures in permeable reactive barriers for the removal of different heavy metal ions from wastewater[J]. Journal of Hazardous Materials,2016,302:437-446. doi: 10.1016/j.jhazmat.2015.09.041 [14] CHEN L, CHEN Z H, CHEN D, et al. Removal of hexavalent chromium from contaminated waters by ultrasound-assisted aqueous solution ball milling[J]. Journal of Environmental Sciences,2017,52:276-283. doi: 10.1016/j.jes.2016.04.006 [15] LEONEL A G, MANSUR A A P, MANSUR H S. Advanced functional nanostructures based on magnetic iron oxide nanomaterials for water remediation: a review[J]. Water Research,2021,190:116693. doi: 10.1016/j.watres.2020.116693 [16] ELJAMAL O, THOMPSON I P, MAAMOUN I, et al. Investigating the design parameters for a permeable reactive barrier consisting of nanoscale zero-valent iron and bimetallic iron/copper for phosphate removal[J]. Journal of Molecular Liquids,2019,299(C):112144. [17] 张道萍, 孟凡生, 王业耀, 等.双金属和多金属系统对零价铁利用效率的改进[J]. 环境科学研究,2016,29(9):1362-1369.ZHANG D P, MENG F S, WANG Y Y, et al. Improvement of zero valent iron efficiency by bimetallic system and multi-metallic system[J]. Research of Environmental Sciences,2016,29(9):1362-1369. [18] 卢欣. 渗透式反应墙对地下水Cr(Ⅵ)去除及电化学解钝化研究[D]. 北京: 清华大学, 2014. [19] CHEN L, JIN S, FALLGREN P H, et al. Electrochemical depassivation of zero-valent iron for trichloroethene reduction[J]. Journal of Hazardous Materials,2012,239/240:265-269. doi: 10.1016/j.jhazmat.2012.08.074 [20] 张金梦. 零价铁电化学法还原地下水中的铬[D]. 沈阳: 沈阳大学, 2017. [21] WANNER C, ZINK S, EGGENBERGER U, et al. Assessing the Cr(Ⅵ) reduction efficiency of a permeable reactive barrier using Cr isotope measurements and 2D reactive transport modeling[J]. Journal of Contaminant Hydrology,2012,131(1/2/3/4):54-63. [22] WANNER C, EGGENBERGER U, MÄDER U. Reactive transport modelling of Cr(Ⅵ) treatment by cast iron under fast flow conditions[J]. Applied Geochemistry,2011,26(8):1513-1523. doi: 10.1016/j.apgeochem.2011.06.015 [23] MELITAS N, CHUFFE-MOSCOSO O, FARRELL J. Kinetics of soluble chromium removal from contaminated water by zerovalent iron media: corrosion inhibition and passive oxide effects[J]. Environmental Science & Technology,2001,35(19):3948-3953. [24] 廉冰娴, 许兵.阳极氧化制备氧化钛薄膜原理剖析[J]. 表面技术,2010,39(4):45-46. doi: 10.3969/j.issn.1001-3660.2010.04.014LIAN B X, XU B. Principle analyses of preparation oxide titanium film using anode oxidation[J]. Surface Technology,2010,39(4):45-46. doi: 10.3969/j.issn.1001-3660.2010.04.014 [25] 陈亮. 零价铁渗透反应格栅中铁的微生物钝化效应及电活化技术[D]. 北京: 中国地质大学(北京), 2012. -

下载:

下载: