Comparative analysis of the environmental impact of virgin and recycled PET fibers based on life cycle assessment

-

摘要:

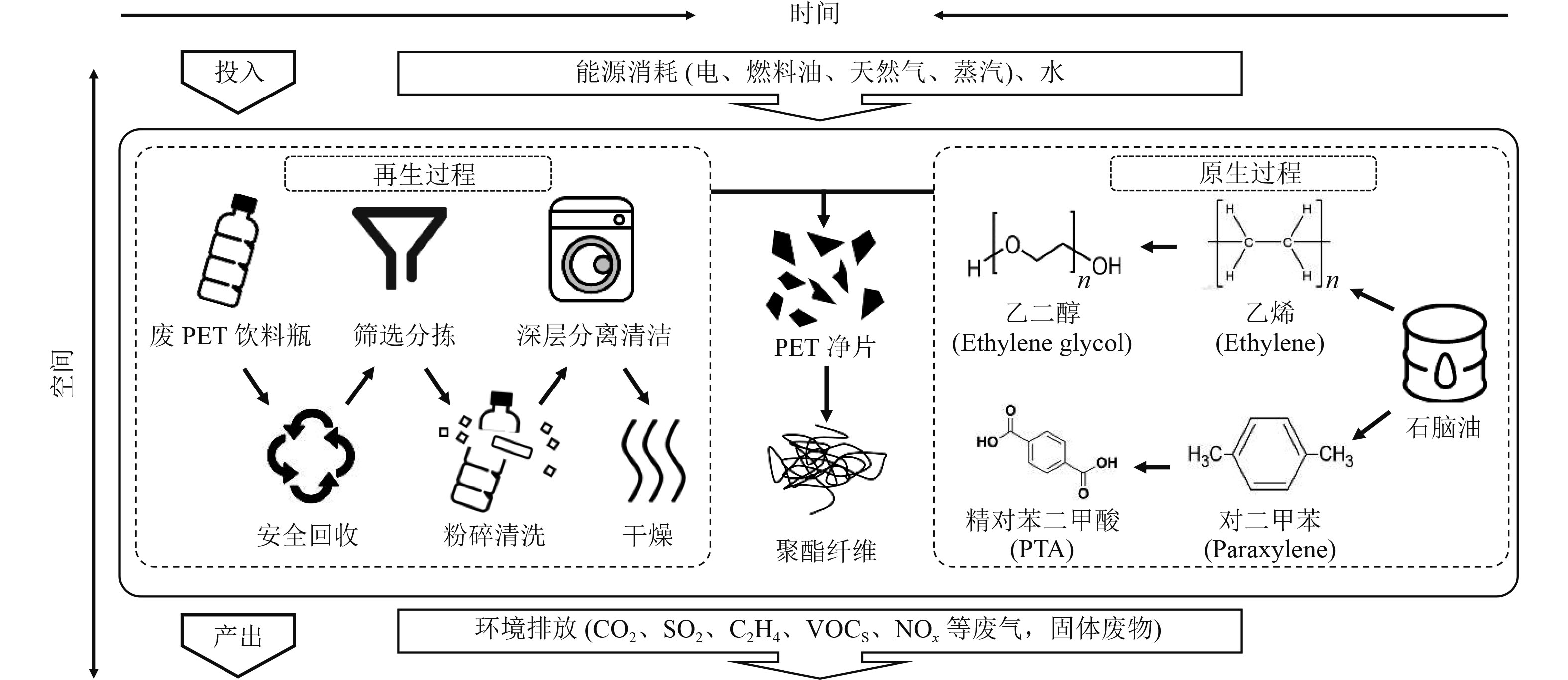

分别以再生长丝〔以回收再生聚对苯二甲酸乙二醇酯(PET)瓶片为原料制备〕及原生长丝(以精对苯二甲酸和乙二醇为原料制备)为分析对象,利用生命周期评价(LCA)方法量化分析生产各阶段的环境影响及贡献,并提出减小环境影响的建议。选取全球变暖潜值、酸化效应潜值、非生物耗竭、光化学臭氧合成、陆地生态毒性潜值 5种环境影响类别进行分类计算。结果表明:再生长丝生产过程中熔融纺丝阶段的环境影响贡献大于物理处理阶段;通过特征化分析和归一化分析,与原生PET长丝相比,生产每100 kg的再生PET长丝全球变暖潜势减少32.09 kg (以CO2计),酸化效应潜值减少0.37 kg (以SO2计);原生PET长丝和再生PET长丝生产过程中环境影响贡献最大的类别均为非生物耗竭。根据生命周期多边形法对5种环境影响类别的综合直观评估结果表明,再生PET长丝相比于原生PET长丝对环境影响更小,可以从能源优化、工艺环节改善等方面减小环境影响。

-

关键词:

- PET /

- 再生长丝 /

- 原生长丝 /

- 生命周期评价(LCA) /

- 环境影响

Abstract:The recycled polyester filaments prepared from recycled polyethylene terephthalate (PET) bottles and virgin filaments prepared from refined terephthalic acid and ethylene glycol were used as the analysis objects. The whole life cycle assessment (LCA) method was used to quantitatively analyze the environmental impact and contribution of each stage of production, and some suggestions for reducing environmental impact were put forward. Five environmental impact categories, including global warming potential (GWP), acidification, abiotic depletions, photochemical oxidation and terrestrial ecotoxicity, were selected for classification and calculation. The results showed that the environmental impact contribution of melt spinning stage in the production process of recycled filament was greater than that of physical treatment stage. Through characterization analysis and normalization analysis, compared with the virgin filament, the global warming potential of recycled filament per 100 kg was reduced by 32.09 kg CO2 eq, and the acidification potential was reduced by 0.37 kg SO2 eq. The most important categories of environmental impact in the production of virgin filament and recycled filament were abiotic depletions. According to the comprehensive and intuitive assessment of five environmental impact categories by the life cycle polygon method, the environmental impact of recycled filament was smaller than that of virgin filament, and the environmental impact could be reduced from the aspects of energy optimization and process improvement.

-

Key words:

- PET /

- recycled filament /

- virgin filament /

- life cycle assessment (LCA) /

- environmental impact

-

表 1 环境影响类别及环境影响因子

Table 1. Environmental impact categories and environmental impact factors

环境影响类别 环境影响因子 单位 全球变暖潜势 CO2 kg(以 CO2 eq.计) 光化学臭氧合成 乙烯( C2H4 ) kg(以 C2H4 eq.计) 陆地生态毒性潜值 二氯苯( DB) kg (以1,4-DB eq.计) 酸化效应潜值 SO2 kg(以 SO2 eq.计) 非生物耗竭 锑(Sb) kg (以Sb eq.计) 表 2 环境影响类别的归一化因子

Table 2. Normalization factors of environmental impact categories

环境影响类别 归一化因子 全球变暖潜势 4.18×1013 陆地生态毒性潜值 3.72×1010 酸化效应潜值 3.18×1011 光化学臭氧合成 2.90×1010 非生物耗竭 1.83×1011 表 3 原生PET长丝和再生PET长丝的特征化总值

Table 3. Total characteristic values of virgin PET filament and recycled PET filament

类别 全球变暖

潜值/kg

(以CO2 eq.计)酸化效应

潜值/kg

(以SO2 eq.计)光化学臭氧

合成/kg (以

C2H4 eq.计)陆地生态

毒性潜值/

kg (以1,4-DB eq.计)非生物耗

竭/kg (以Sb eq.计)原生长丝 149.29 2.33 1.05 0.03 1.60 再生长丝 117.21 1.96 0.08 0.02 1.86 -

[1] 毕莹莹, 刘景洋, 董莉, 等.我国废PET饮料瓶产生量与回收水平研究[J]. 环境工程技术学报,2022,12(1):185-190.BI Y Y, LIU J Y, DONG L, et al. Study on the production and recovery level of waste PET drinking bottles in China[J]. Journal of Environmental Engineering Technology,2022,12(1):185-190. [2] 李少山.PTA-PET-短纤产业链的市场回顾与未来趋势分析[J]. 山东化工,2018,47(8):108-113.LI S S. The PTA-market review and future trend of PET staple fiber industry chain analysis[J]. Shandong Chemical Industry,2018,47(8):108-113. [3] 薛芳峰, 胡永笑, 付洪波, 等.PA6/PET切片熔融共混纺丝工艺介绍[J]. 合成纤维,2009,38(11):44-46. doi: 10.3969/j.issn.1001-7054.2009.11.012XUE F F, HU Y X, FU H B, et al. Research on the process of PA6/PET blend spinning[J]. Synthetic Fiber in China,2009,38(11):44-46. doi: 10.3969/j.issn.1001-7054.2009.11.012 [4] 王琪, 瞿金平, 石碧, 等.我国废弃塑料污染防治战略研究[J]. 中国工程科学,2021,23(1):160-166.WANG Q, QU J P, SHI B, et al. Prevention and control of waste plastics pollution in China[J]. Strategic Study of CAE,2021,23(1):160-166. [5] NIKLES D E, FARAHAT M S. New motivation for the depolymerization products derived from poly(ethylene terephthalate) (PET) waste: a review[J]. Macromolecular Materials and Engineering,2005,290(1):13-30. doi: 10.1002/mame.200400186 [6] 曹泳琳, 严玉蓉, 邢玉静, 等.废旧PET回收利用进展[J]. 合成材料老化与应用,2021,50(2):128-131.CAO Y L, YAN Y R, XING Y J, et al. Review on recycling of PET and its applications[J]. Synthetic Materials Aging and Application,2021,50(2):128-131. [7] 周迎鑫, 翁云宣, 张彩丽, 等.聚对苯二甲酸乙二醇酯回收技术和标准现状[J]. 中国塑料,2021,35(8):162-171.ZHOU Y X, WENG Y X, ZHANG C L, et al. Review of recovery technology and standard status of poly (ethylene terephthalate)[J]. China Plastics,2021,35(8):162-171. [8] 钱亚茹, 石磊磊, 沈茜, 等.淡水环境中微塑料污染及毒性效应研究进展[J]. 环境工程技术学报,2022,12(4):1096-1104.QIAN Y R, SHI L L, SHEN Q, et al. Research progress on pollution and toxic effects of microplastics in freshwater environment[J]. Journal of Environmental Engineering Technology,2022,12(4):1096-1104. [9] AWAJA F, PAVEL D. Recycling of PET[J]. European Polymer Journal,2005,41(7):1453-1477. doi: 10.1016/j.eurpolymj.2005.02.005 [10] CHU J W, CAI Y P, LI C H, et al. Dynamic flows of polyethylene terephthalate (PET) plastic in China[J]. Waste Management,2021,124:273-282. doi: 10.1016/j.wasman.2021.01.035 [11] 2021年碳中和背景下PET瓶可持续发展报告[EB/OL][2022-08-20].https://www.cls.cn/detail/825716. [12] 徐卫星.《我国PET饮料包装回收利用情况研究报告》发布 我国PET饮料瓶回收率超94%[J]. 饮料工业,2020,23(5):78-79. doi: 10.3969/j.issn.1007-7871.2020.05.020 [13] SHEN L, WORRELL E, PATEL M K. Open-loop recycling: a LCA case study of PET bottle-to-fibre recycling[J]. Resources, Conservation and Recycling,2010,55(1):34-52. doi: 10.1016/j.resconrec.2010.06.014 [14] ZHANG R R, MA X T, SHEN X X, et al. PET bottles recycling in China: an LCA coupled with LCC case study of blanket production made of waste PET bottles[J]. Journal of Environmental Management,2020,260:110062. doi: 10.1016/j.jenvman.2019.110062 [15] BAŁAZIŃSKA M, KRUCZEK M, BONDARUK J. The environmental impact of various forms of waste PET bottle management[J]. International Journal of Sustainable Development & World Ecology,2021,28(5):473-480. [16] NAKATANI J, FUJII M, MORIGUCHI Y, et al. Life-cycle assessment of domestic and transboundary recycling of post-consumer PET bottles[J]. The International Journal of Life Cycle Assessment,2010,15(6):590-597. doi: 10.1007/s11367-010-0189-y [17] SALEH Y. Comparative life cycle assessment of beverages packages in Palestine[J]. Journal of Cleaner Production,2016,131:28-42. doi: 10.1016/j.jclepro.2016.05.080 [18] RENOU S, THOMAS J S, AOUSTIN E, et al. Influence of impact assessment methods in wastewater treatment LCA[J]. Journal of Cleaner Production,2008,16(10):1098-1105. doi: 10.1016/j.jclepro.2007.06.003 [19] JOLLIET O, MARGNI M, CHARLES R, et al. IMPACT 2002+: a new life cycle impact assessment methodology[J]. The International Journal of Life Cycle Assessment,2003,8(6):324. doi: 10.1007/BF02978505 [20] HUIJBREGTS M A J, STEINMANN Z J N, ELSHOUT P M F, et al. Correction to: ReCiPe2016: a harmonised life cycle impact assessment method at midpoint and endpoint level[J]. The International Journal of Life Cycle Assessment,2020,25(8):1635. doi: 10.1007/s11367-020-01761-5 [21] GOEDKOOP M, SPRIENSMA R. The Eco-indicator '99, a damage oriented method for Life Cycle Impact Assessment: methodology report, Amersfoort, PRé Consultants[M].Amersfoort, The Netherlands:Vrom Zoetermeer, PRé Consultants b.v., 2000. [22] SLEESWIJK A W, van OERS L F C M, GUINÉE J B, et al. Normalisation in product life cycle assessment: an LCA of the global and European economic systems in the year 2000[J]. Science of the Total Environment,2008,390(1):227-240. doi: 10.1016/j.scitotenv.2007.09.040 [23] DANIEL S E, TSOULFAS G T, PAPPIS C P, et al. Aggregating and evaluating the results of different Environmental Impact Assessment methods[J]. Ecological Indicators,2004,4(2):125-138. doi: 10.1016/j.ecolind.2004.01.003 [24] 郭亚琴, 向丽娟.精对苯二甲酸生产工艺的发展研究[J]. 化工管理,2019(33):194. doi: 10.3969/j.issn.1008-4800.2019.33.129 [25] 俞晓梅.我国精对苯二甲酸行业专利技术分析[J]. 南京师范大学学报(工程技术版),2011,11(02):68-72. [26] 江天诰.乙二醇的生产工艺技术研究[J]. 山西化工,2021,41(5):52-53. doi: 10.16525/j.cnki.cn14-1109/tq.2021.05.17JIANG T G. Study on production technology of ethylene glycol[J]. Shanxi Chemical Industry,2021,41(5):52-53. doi: 10.16525/j.cnki.cn14-1109/tq.2021.05.17 [27] 刘洪春.再生PET化纤行业发展情况及其环境保护[J]. 今日财富,2017(15):191-192. [28] 周炳炎, 郭琳琳, 李丽, 等.我国塑料包装废物的产生和回收特性及管理对策[J]. 环境科学研究,2010,23(3):282-287. doi: 10.13198/j.res.2010.03.36.zhouby.005ZHOU B Y, GUO L L, LI L, et al. Characteristics of generation and recycling of plastic packaging waste in China and management countermeasures[J]. Research of Environmental Sciences,2010,23(3):282-287. ⊗ doi: 10.13198/j.res.2010.03.36.zhouby.005 -

下载:

下载: