Evaluation method of gasoline particulate filter regeneration interval mileage in a low-temperature environment

-

摘要:

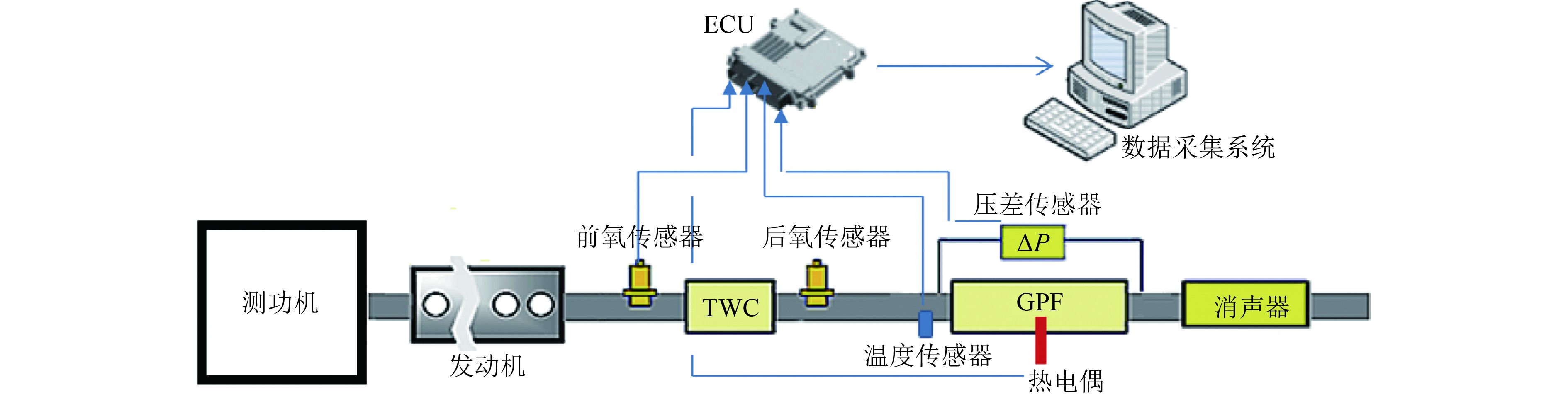

对汽油机颗粒捕集器(gasoline particulate filter,GPF)碳载量估算的温度修正方法,以及低温环境下的GPF再生间隔里程进行研究。利用发动机台架试验测量了GPF颗粒物再生反应速率,通过对数作图法拟合反应速率得到再生反应活化能,氧和颗粒物的反应活化能为81.6~91.4 kJ/mol,二氧化碳和颗粒物的反应活化能为159.2~218.9 kJ/mol。基于反应活化能计算了不同环境温度下颗粒物再生反应速率的修正系数;测量试验车低温冷启动阶段颗粒物累积速度,计算颗粒物排放的温度修正系数。以轻型车排放国六标准I型试验为基础,利用颗粒物再生反应速率和排放的温度修正系数对低温环境下GPF主动再生间隔里程进行了仿真。与寒区道路试验中获得的实际GPF颗粒物累积数据对比,仿真结果能较为准确地预测GPF在寒区不同工况下的颗粒物累积速度。试验和仿真结果均显示车辆低速行驶时GPF内颗粒物累积速度更易受低温环境影响。

Abstract:The gasoline particulate filter (GPF) regeneration interval mileage in a low-temperature environment was studied based on a temperature correction method for GPF soot load estimation.The GPF soot regeneration action rate was measured by the engine dyno test, and the activation energy of the regeneration reaction was obtained by the logarithm method and the line fitting method. It was shown that the activation energy of oxygen and soot was 81.6-91.4 kJ/mol, and that of carbon dioxide and soot was 159.2-218.9 kJ/mol. The activation energy was then used to calculate the correction coefficients for the soot regeneration action rate in variant environment temperatures. The accumulated velocity of the soots in the cold start stage of the test vehicle was measured, and the correction coefficients for soot emission in a low-temperature environment were acquired. Based on the type I test of CHINA 6 for light-duty vehicle emission, GPF active regeneration interval mileage in a low-temperature environment was simulated by applying the temperature correction coefficient of soot emissions and regeneration rate. Compared with GPF soot accumulation data from test vehicles driving on road in cold region, the simulation result had enough precision to predict GPF soot load accumulation rate for vehicle usage under different working conditions in cold region. Both the simulation and test results indicated that GPF soot accumulation rate was easily affected by low temperature when the vehicle running at low speed.

-

表 1 GPF与排气歧管端口距离

Table 1. Distance between GPF and exhaust manifold

试验车序号 车型 GPF距排气歧管距离/mm 发动机类型和排量/L 1 SUV 1 230 GDI,1.5 2 载客汽车 660 PFI,2.0 3 轻型货车 760 PFI,2.4 4 SUV 810 GDI,1.8 注:GDI为燃油直喷;PFI为燃油进气道喷射。 表 2 GPF再生速率台架测试参数

Table 2. GPF regeneration rate dyno test parameters

试验车序号 转速/(r/min) IMEP/bar 再生反应条件 GPF床温/℃ 颗粒物再生量/g 颗粒物流量/(mg/s) 反应时间/s 颗粒物再生反应速率/s−1 1 3 000 0 DFCO 514.5 0.8 0 64 1.164×10−3 1 3 000 0 DFCO 613.5 4.2 0 86 6.017×10−3 1 3 000 0 DFCO 761.7 3.5 0 45 2.322×10−2 1 2 000 9.64 λ=1 521.1 1.4 0.028 100 3 100 7.233×10−5 1 2 000 11.53 λ=1 665.3 6.0 0.008 160 2 899 8.898×10−4 1 3 500 14.71 λ=1 784.8 6.5 0.129 000 756 4.801×10−3 2 2 000 0 DFCO 450.0 0.1 0 165 1.060×10−4 2 2 400 0 DFCO 550.0 0.7 0 167 6.958×10−4 2 3 200 0 DFCO 645.0 3.5 0 160 4.423×10−3 2 3 600 0 DFCO 685.0 4.1 0 155 8.197×10−3 2 1 500 9.17 λ=1 366.4 0.0 0.000 953 4 200 3.843×10−7 2 2 000 9.77 λ=1 456.9 0.3 0.001 040 3 600 1.427×10−5 2 3 200 12.19 λ=1 600.5 1.4 0.002 560 2 040 1.618×10−4 2 3 600 20.35 λ=1 754.1 4.3 0.059 600 900 1.467×10−3 3 3 600 0 DFCO 602.8 1.3 0 26 1.099×10−2 3 3 600 0 DFCO 651.9 4.5 0 66 2.476×10−2 3 3 600 0 DFCO 697.9 3.0 0 56 7.517×10−2 3 3 600 0 DFCO 762.6 5.5 0 36 1.384×10−2 3 2 800 9.89 λ=1 596.0 0.0 0.000 018 1 755 8.973×10−6 3 3 600 12.04 λ=1 717.0 0.3 0.000 306 710 6.767×10−5 3 4 000 14.32 λ=1 815.0 4.9 0.056 400 601 1.146×10−3 4 2 400 0 DFCO 592.4 0.6 0 21 3.444×10−3 4 2 400 0 DFCO 644.1 1.1 0 10 1.245×10−2 4 2 800 0 DFCO 719.5 2.3 0 41 1.154×10−2 4 2 800 0 DFCO 736.0 2.5 0 10 4.761×10−2 4 1 600 8.59 λ=1 465.3 0.1 0.001 760 1 800 2.216×10−6 4 2 400 12.15 λ=1 589.7 0.2 0.005 420 2 400 2.094×10−5 4 2 400 13.68 λ=1 669.2 2.2 0.006 100 1 200 3.719×10−4 4 2 400 14.37 λ=1 729.0 3.0 0.004 690 1 200 4.804×10−4 表 3 GPF再生反应的活化能

Table 3. GPF Regeneration action active energy

试验车序号 再生反应条件 Ea/(kJ/mol) 回归系数(R2) 1 DFCO 81.7 0.991 3 λ=1 110.8 0.999 6 2 DFCO 83.2 0.944 5 λ=1 113.0 0.985 9 3 DFCO 91.4 0.920 3 λ=1 169.4 0.952 7 4 DFCO 81.6 0.809 0 λ=1 133.3 0.953 2 表 4 再生反应过程式(4)的活化能

Table 4. Active energy of regeneration process (4)

试验车序号 Ea/(kJ/mol) 回归系数(R2) 1 161.3 0.998 0 2 159.2 0.913 7 3 218.9 0.969 5 4 183.6 0.960 3 表 5 冷启动阶段颗粒物累积量

Table 5. Soot accumulation amount during cold engine start

g 试验车序号 −10 ℃ −20 ℃ −30 ℃ 1 0.10 0.16 0.32 2 0.23 0.47 0.60 3 0.15 0.53 0.80 4 0.20 0.34 0.45 表 6 WLTC循环中GPF中颗粒物再生情况

Table 6. GPF regeneration status in WLTC test

试验车序号 测试循环 GPF平均

床温/℃颗粒物累

积量/mg颗粒物再

生量/mgDFCO再

生占比/%1 WLTC低速 261.4 2.708 0.002 66.7 WLTC中速 375.9 1.568 0.319 70.9 WLTC高速 419.1 1.712 0.907 82.6 WLTC超高速 521.3 3.067 8.372 93.5 WLTC 374.9 9.055 9.595 92.1 2 WLTC低速 446.6 26.211 11.248 86.2 WLTC中速 612.4 16.982 25.114 87.6 WLTC高速 674.6 16.903 38.093 88.4 WLTC超高速 772.9 22.465 50.372 90.4 WLTC 602.8 82.570 124.840 88.8 3 WLTC低速 386.8 67.102 25.141 96.1 WLTC中速 502.2 17.130 52.419 93.8 WLTC高速 553.4 16.558 56.038 94.2 WLTC超高速 644.7 25.751 121.484 96.0 WLTC 503.1 126.568 255.084 95.2 4 WLTC低速 447.3 9.497 2.035 91.6 WLTC中速 566.8 8.924 3.871 87.1 WLTC高速 613.7 10.015 10.224 88.5 WLTC超高速 695.6 15.099 23.693 93.2 WLTC 562.5 43.539 39.831 91.3 表 7 WLTC循环DFCO统计

Table 7. DFCO statistics in WLTC test

试验车序号 DFCO总次数 DFCO 最后一次DFCO 输氧量/g GPF平均床温/℃ 输氧量/g GPF平均床温/℃ 颗粒物再生占比/% 1 32 105.65 418.2 29.87 507.6 79.8 2 58 196.23 654.1 41.58 834.5 33.1 3 78 196.81 507.8 32.52 615.9 44.6 4 76 178.59 591.4 44.85 698.4 48.9 表 8 GPF主动再生间隔里程试验循环

Table 8. Test cycle for GPF active regeneration interval mileage verification

测试循环 循环描述 行驶里

程/km平均车速 /

(km/h)循环1 WLTC循环 23.4 46.5 循环2 WLTC循环,无最后DFCO 22.3 46.5 循环3 WLTC循环,低+中+高速循环 15.1 36.8 循环4 WLTC循环,低+中速循环 7.94 27.9 表 9 道路试验中GPF的颗粒物累积

Table 9. GPF soot load accumulation in field driving test

试验车

序号城市拥堵道路 城市综合道路 城市高速道路 行驶里

程/km碳载量/g 行驶里

程/km碳载量/g 行驶里

程/km碳载量/g 1 600 1.6 1 102 0.9 1 006 0.0 2 346 0.4 3 599 4.0 1 118 3.7 1 162 0.0 4 545 0.9 938 0.6 998 0.1 -

[1] 李红, 彭良, 毕方, 等.我国PM2.5与臭氧污染协同控制策略研究[J]. 环境科学研究,2019,32(10):1763-1778.LI H, PENG L, BI F, et al. Strategy of coordinated control of PM2.5 and ozone in China[J]. Research of Environmental Sciences,2019,32(10):1763-1778. [2] 李建峰, 王思儒, 郑冬勇, 等.超细颗粒物的污染行为与毒性效应研究[J]. 广东化工,2018,45(7):127-128.LI J F, WANG S R, ZHENG D Y, et al. Research on the pollution behavior and toxic effects of ultrafine particulate matter[J]. Guangdong Chemical Industry,2018,45(7):127-128. [3] YANG J C, ROTH P, DURBIN T D, et al. Gasoline particulate filters as an effective tool to reduce particulate and polycyclic aromatic hydrocarbon emissions from gasoline direct injection (GDI) vehicles: a case study with two GDI vehicles[J]. Environmental Science & Technology,2018,52(5):3275-3284. [4] 王军方, 尹航, 王宏丽, 等.轻型汽油车国六排放标准可行性研究[J]. 环境工程技术学报,2017,7(6):661-665. doi: 10.3969/j.issn.1674-991X.2017.06.091WANG J F, YIN H, WANG H L, et al. Study on probability of compliance with China 6 standard for the emission from light duty gasoline vehicles[J]. Journal of Environmental Engineering Technology,2017,7(6):661-665. doi: 10.3969/j.issn.1674-991X.2017.06.091 [5] 龚少南. 汽油机颗粒捕集器的建模与再生控制[D]. 合肥: 合肥工业大学, 2020. [6] 范明哲, 张宾, ALEXANDER S, 等.汽油机GPF炭载量模型和再生策略的试验研究[J]. 内燃机与动力装置,2018,35(6):1-10.FAN M Z, ZHANG B, ALEXANDER S, et al. Experimental study on soot model and regeneration strategy of gasoline particulate filter[J]. Internal Combustion Engine & Powerplant,2018,35(6):1-10. [7] 环境保护部, 国家质量监督检验检疫总局. 轻型汽车污染物排放限值及测量方法: GB 18352.6—2016[S]. 北京: 中国环境科学出版社, 2020. [8] RODRIGUEZ F. Investigations on the pollutant emissions of gasoline direct injection engines during cold-start[R]. Cambridge: Massachusetts Institute of Technology, 2016. [9] BOGARRA M, HERREROS J M, TSOLAKIS A, et al. Gasoline direct injection engine soot oxidation: fundamentals and determination of kinetic parameters[J]. Combustion and Flame,2018,190:177-187. doi: 10.1016/j.combustflame.2017.11.027 [10] 姚塽, 汪侃, 张许扬, 等.汽油机颗粒捕集器再生平衡状态的仿真研究[J]. 内燃机工程,2021,42(3):93-99. doi: 10.13949/j.cnki.nrjgc.2021.03.014YAO S, WANG K, ZHANG X Y, et al. Simulation study on the regeneration equilibrium state of gasoline particulate filters[J]. Chinese Internal Combustion Engine Engineering,2021,42(3):93-99. doi: 10.13949/j.cnki.nrjgc.2021.03.014 [11] BOGER T, ROSE D, NICOLIN P, et al. Oxidation of soot (Printex® U) in particulate filters operated on gasoline engines[J]. Emission Control Science and Technology,2015,1(1):49-63. doi: 10.1007/s40825-015-0011-1 [12] PER N, DOMINIK R, FLORIAN K, et al. Modeling of the soot oxidation in gasoline particulate filters[J]. SAE International Journal of Engines, 2015, 8(3): 1253-1260. [13] LUO Y Q, ZHU L, FANG J H, et al. Size distribution, chemical composition and oxidation reactivity of particulate matter from gasoline direct injection (GDI) engine fueled with ethanol-gasoline fuel[J]. Applied Thermal Engineering,2015,89:647-655. doi: 10.1016/j.applthermaleng.2015.06.060 [14] WANG C M, XU H M, HERREROS J M, et al. Fuel effect on particulate matter composition and soot oxidation in a direct-injection spark ignition (DISI) engine[J]. Energy & Fuels,2014,28(3):2003-2012. [15] WANG-HANSEN C, ERICSSON P, LUNDBERG B, et al. Characterization of particulate matter from direct injected gasoline engines[J]. Topics in Catalysis, 2013, 56(1/2/3/4/5/6/7/8): 446-451. [16] STANMORE B R, BRILHAC J F, GILOT P. The oxidation of soot: a review of experiments, mechanisms and models[J]. Carbon,2001,39(15):2247-2268. doi: 10.1016/S0008-6223(01)00109-9 [17] DHRUVANG R, SIMONA O, ZORAN F, et al. Experimental investigation of soot accumulation and regeneration in a catalyzed gasoline particulate filter utilizing particulate quantification and gas speciation measurements[C]//ASME 2018 Internal Combustion Engine Fall Technical Conference. San Diego, 2018. [18] 南征, 李楠, 刘海涛, 等.不同载体汽油机颗粒捕集器再生性能试验研究[J]. 内燃机与动力装置,2021,38(6):29-35. doi: 10.19471/j.cnki.1673-6397.2021.06.005NAN Z, LI N, LIU H T, et al. Experimental study on regeneration performance of gasoline particulate filter with different carriers[J]. Internal Combustion Engine & Powerplant,2021,38(6):29-35. doi: 10.19471/j.cnki.1673-6397.2021.06.005 [19] 崔亚男.汽油机颗粒捕集器台架标定方法研究[J]. 小型内燃机与车辆技术,2020,49(1):73-78.CUI Y N. Research on gasoline engine particulate filter bench calibration[J]. Small Internal Combustion Engine and Vehicle Technique,2020,49(1):73-78. [20] 李树宇.汽油颗粒捕集器(GPF)累碳及再生状态研究[J]. 柴油机设计与制造,2021,27(3):33-36.LI S Y. Study on Carbon accumulation and regeneration status of gasoline particle catcher[J]. Design and Manufacture of Diesel Engine,2021,27(3):33-36. [21] 陈龙, 李儒龙, 许瑞, 等. GPF再生消耗模型标定方法研究[C]//2020中国汽车工程学会年会论文集(3). 北京: 机械工业出版社, 2021: 838-842 [22] 邹秀清. 不同环境下的汽油机GPF服务站再生研究[C]//2020中国汽车工程学会年会论文集(2). 北京: 机械工业出版社, 2021: 743-747 [23] 气象局. 中国气象年鉴2019[M]. 北京: 中国气象出版社, 2020: 556-557. [24] YEHLIU K, VANDER WAL R L, ARMAS O, et al. Impact of fuel formulation on the nanostructure and reactivity of diesel soot[J]. Combustion and Flame,2012,159(12):3597-3606. doi: 10.1016/j.combustflame.2012.07.004 [25] SEONG H, LEE K, CHOI S. Effects of engine operating parameters on morphology of particulates from a gasoline direct injection (GDI) engine[C]//SAE Technical Paper Series. Warrendale: SAE International, 2013. [26] KAPTEIJN F, MEIJER R, MOULIJN J A, et al. On why do different carbons show different gasification rates: a transient isotopic CO2 gasification study[J]. Carbon,1994,32(7):1223-1231. doi: 10.1016/0008-6223(94)90106-6 [27] ARUNACHALAM H, POZZATO G, HOFFMAN M A, et al. Modeling the thermal and soot oxidation dynamics inside a ceria-coated gasoline particulate filter[J]. Control Engineering Practice,2020,94:104199. doi: 10.1016/j.conengprac.2019.104199 [28] 朱庆功, 刘俊女, 赵笑春, 等.北京市轻型汽油车蒸发排放总量评估[J]. 中国环境科学,2022,42(3):1066-1072. doi: 10.19674/j.cnki.issn1000-6923.2022.0070ZHU Q G, LIU J N, ZHAO X C, et al. Estimation of light-duty vehicles total evaporative emissions in Beijing[J]. China Environmental Science,2022,42(3):1066-1072. doi: 10.19674/j.cnki.issn1000-6923.2022.0070 [29] 王军方, 丁焰, 王爱娟, 等.北京市机动车行驶工况研究[J]. 环境工程技术学报,2012,2(3):240-246.WANG J F, DING Y, WANG A J, et al. Study of vehicle driving cycle modes on road in Beijing[J]. Journal of Environmental Engineering Technology,2012,2(3):240-246. [30] MOSES-DEBUSK M, STOREY J M E, EIBL M A, et al. Nonuniform oxidation behavior of loaded gasoline particulate filters[J]. Emission Control Science and Technology,2020,6(3):301-314. □ doi: 10.1007/s40825-020-00166-y -

下载:

下载: