Experimental study on the making of sintered brick using municipal sludge in Shenyang City

-

摘要:

以沈阳市政污泥为研究对象,开展污泥混合煤矸石和页岩材料制烧结砖的操作过程和产品应用的可行性研究。通过原材料测试评价和正交试验优化混配材料比例来确定最佳烧结制度,在此基础上,评估污泥添加量对砖性能的影响和样砖的环境安全性。结果表明:3种材料混配制砖的最佳烧结制度是污泥添加量为5%,烧结温度为1 050 ℃,烧结时间为9 h,该烧结制度下烧结砖样品检测指标达到或优于GB 5101—2003《烧结普通砖》的要求;混配材料试验中污泥添加量为0%~15%时,制得的烧结砖样品的抗压强度均能达到出厂标准;污泥添加量为0%~20%,烧结温度为1 050 ℃,烧结时间为9 h时,制得的烧结砖样品对环境安全无害。

Abstract:Taking municipal sludge of Shenyang City as an example, the operation processes and product application feasibility of sintered brick made of sludge mixed with coal gangue and shale were explored. The optimal sintering system was determined by optimizing the proportion of mixed materials through raw material test and evaluation and orthogonal experiment. On this basis, the influence of sludge addition on the performance of brick and the environmental safety of brick samples were evaluated. The results showed: The optimum sintering system for brick making with three kinds of mixed materials was as follows: sludge addition was 5%, sintering temperature was 1 050 ℃ and sintering time was 9 h. The performance of sintered brick samples met or exceeded Fired Common Bricks ( GB 5101-2003). In the test of mixed materials, the compressive strength of sintered bricks with sludge addition of 0%-15% could meet the factory standard. The sintered bricks with 0%-20% sludge, 1 050 ℃ sintering temperature and 9 h sintering time were safe and harmless for the environment.

-

表 1 原材料发热量及配比

Table 1. Calorific value and ratio of raw materials

发热量/(cal/g) 原材料配比/% 污泥 康平矸石 铁岭矸石 铁岭页岩 538 0 60 20 20 542 5 46 29 20 543 10 37 33 20 546 15 26 39 20 548 20 26 44 20 表 2 正交试验因素水平

Table 2. Factor level table of orthogonal test

序号 污泥添加量(A)/% 烧结温度(B)/℃ 烧结时间(C)/h 1 5 950 8 2 10 1000 9 3 15 1050 10 表 3 三因素三水平正交试验

Table 3. Orthogonal test table of three factors and three levels

序号 污泥添加量(A)/% 烧结温度(B)/℃ 烧结时间(C)/h 1 5 950 8 2 5 1000 10 3 5 1050 9 4 10 950 10 5 10 1000 9 6 10 1050 8 7 15 950 9 8 15 1000 8 9 15 1050 10 表 4 原材料物质成分及理化性质

Table 4. Material composition and physical and chemical properties of raw materials

原料 SiO2浓度/% Al2O3浓度/% Fe2O3浓度/% CaO浓度/% MgO浓度/% K2O浓度/% SO3浓度/% 发热量/(cal/g) pH 烧失率/% 市政污泥 13.52 13.52 10.37 2.92 1.53 0.87 0.87 2 018 6.3 41.0 康平矸石 46.64 13.89 11.20 5.16 1.41 1.22 0.91 907 9.7 16.5 铁岭矸石 57.25 15.50 7.94 1.68 1.25 1.93 0 289 10.0 12.9 铁岭页岩 58.45 15.92 5.92 5.95 1.89 6.45 0 0 8.7 表 5 原材料重金属浓度

Table 5. Heavy metal contents of raw materials

mg/L 原料 镉 铅 铬 锌 铜 镍 砷 汞 市政污泥 2.35 53.13 132.26 1086.77 234.38 54.27 12.36 0.280 康平矸石 0.09 12.21 2.85 75.80 25.87 29.96 16.30 0.004 铁岭矸石 0.19 12.65 24.13 73.24 23.73 41.88 2.59 0.008 铁岭页岩 0.12 5.81 3.70 19.04 26.76 15.56 3.64 0.000 GB/T 25031—2010标准限值 20 300 1000 4000 1500 200 75 5 表 6 正交试验结果

Table 6. Results of orthogonal test

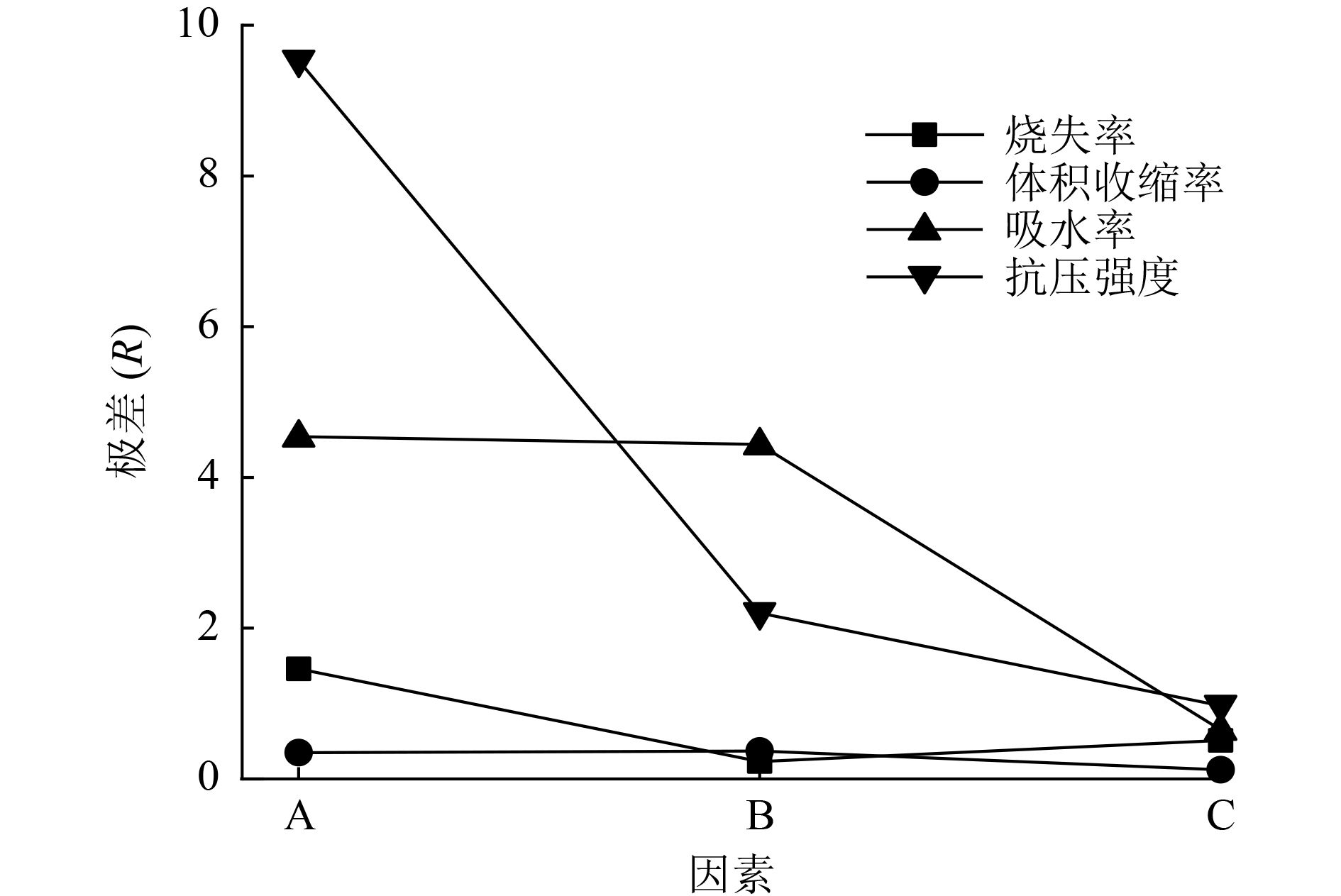

序号 烧失率/% 体积收缩率/% 吸水率/% 抗压强度/MPa 1 16.99 1.02 17.10 16.6 2 17.12 1.23 16.10 16.2 3 16.25 1.84 12.29 20.4 4 16.13 1.42 21.55 16.3 5 16.50 1.43 19.31 14.8 6 16.40 1.74 18.24 15.5 7 14.91 1.03 18.93 12.2 8 15.10 1.27 17.12 12.9 9 15.94 1.28 13.73 15.1 表 7 正交试验k值与极差分析

Table 7. K value and range analysis of orthogonal test

项目 污泥添加量(A) 烧结温度(B) 烧结时间(C) 烧失率 k1 16.78 16.00 16.16 k2 16.34 16.24 15.88 k3 15.31 16.19 16.39 R 1.47 0.24 0.51 收缩率 k1 1.36 1.15 1.33 k2 1.53 1.31 1.43 k3 1.18 1.62 1.31 R 0.35 0.47 0.12 吸水率 k1 15.70 19.20 17.40 k2 19.70 17.51 16.84 k3 16.60 14.75 17.13 R 4.00 4.45 0.56 抗压强度 k1 17.73 12.53 12.50 k2 8.20 12.30 13.47 k3 13.40 14.50 13.37 R 9.53 2.20 0.97 表 8 烧结砖样品重金属浸出浓度

Table 8. Leaching concentrations of heavy metals from sintered brick samples

mg/L 污泥添加量/% 镉 铅 铬 锌 铜 镍 砷 汞 0 0.03 0.31 0.97 3.62 2.85 0.91 2.39 0.001 5 0.03 0.27 0.78 4.11 3.10 1.99 1.12 0.001 10 0.02 0.19 0.62 6.72 3.13 1.20 1.97 0.001 15 0.04 0.27 1.33 6.39 7.27 4.38 1.58 0.001 20 0.04 0.34 1.28 15.78 6.25 3.91 2.02 0.002 GB 5085.3—

2007标准限值1 5 15 100 100 5 5 0.1 -

[1] 胡维杰.我国污水处理厂污泥处理处置需关注的若干内容[J]. 给水排水,2019,55(3):35-41.HU W J. Some contents of concern for sludge treatment and disposal of wastewater treatment plants in China[J]. Water & Wastewater Engineering,2019,55(3):35-41. [2] 宋承楠, 孙志.市政污泥资源化利用与水泥窑协同处置[J]. 中国建材,2022,71(1):132-134.SONG C N, SUN Z. Municipal sludge resource utilization and cement kiln disposa[J]. China Building Materials,2022,71(1):132-134. [3] 林昱廷, 彭娅娅, 苏冰琴, 等.污泥处理及资源化技术研究进展[J]. 化工设计通讯,2021,47(1):176-177. doi: 10.3969/j.issn.1003-6490.2021.01.085LIN Y T, PENG Y Y, SU B Q, et al. Research progress of sludge treatment and recycling technology[J]. Chemical Engineering Design Communications,2021,47(1):176-177. doi: 10.3969/j.issn.1003-6490.2021.01.085 [4] TAY J H, SHOW K Y. Utilization of municipal wastewater sludge as building and construction materials[J]. Resources, Conservation and Recycling,1992,6(3):191-204. doi: 10.1016/0921-3449(92)90030-6 [5] 李明东, 丛新, 张志峰.资源化利用废泥生产建材的现状与展望[J]. 环境工程,2016,34(4):116-121. doi: 10.13205/j.hjgc.201604024LI M D, CONG X, ZHANG Z F. Reutilization of waste mud for producing building materials: a review and outlook[J]. Environmental Engineering,2016,34(4):116-121. doi: 10.13205/j.hjgc.201604024 [6] 赵玉鑫, 刘颖杰. 城市污泥处理技术及工程实例[M]. 北京: 化学工业出版社, 2016. [7] 田野.污水污泥处置与建材化利用现状探讨[J]. 四川水泥,2017(2):121. [8] 王方舟, 刘雪瑜, 肖书虎, 等.污泥磷形态及响应面分析法优化释磷试验[J]. 环境工程技术学报,2021,11(1):151-157. doi: 10.12153/j.issn.1674-991X.20200060WANG F Z, LIU X Y, XIAO S H, et al. Experimental study on phosphorus form of sludge and response surface method to optimize phosphorus release[J]. Journal of Environmental Engineering Technology,2021,11(1):151-157. doi: 10.12153/j.issn.1674-991X.20200060 [9] 周俏俏, 葛仕福, 丁晶, 等.CaO调质污泥自然失水特性及数学模型研究[J]. 环境工程技术学报,2022,12(3):802-808.ZHOU Q Q, GE S F, DING J, et al. Study on natural water loss characteristics and mathematical model of CaO conditioned sludge[J]. Journal of Environmental Engineering Technology,2022,12(3):802-808. [10] 钱觉时, 谢从波, 谢小莉, 等.城市生活污水污泥建材利用现状与研究进展[J]. 建筑材料学报,2014,17(5):829-836.QIAN J S, XIE C B, XIE X L, et al. Utilization of municipal sewage sludge as building materials: a state-of-the-art review[J]. Journal of Building Materials,2014,17(5):829-836. [11] 赵华, 赵姝蓉.利用煤矸石生产内燃砖的探索[J]. 化工技术与开发,2010,39(9):42-43.ZHAO H, ZHAO S R. Exploratory production of coal gangue brick[J]. Technology & Development of Chemical Industry,2010,39(9):42-43. [12] 邓振伟, 于萍, 陈玲.SPSS软件在正交试验设计、结果分析中的应用[J]. 电脑学习,2009(5):15-17.DENG Z W, YU P, CHEN L. Application of SPSS software in orthogonal design and result analysis[J]. Computer Study,2009(5):15-17. [13] 程文环. 泥质页岩煤矸石对混凝土常温及高温性能影响[D]. 哈尔滨: 哈尔滨工业大学, 2015. [14] 王建培, 于敦喜, 樊斌, 等.氧/燃料燃烧条件下方解石的转化行为[J]. 工程热物理学报,2014,35(6):1240-1243.WANG J P, YU D X, FAN B, et al. The transformation behavior of calcite during oxy-fuel combustion[J]. Journal of Engineering Thermophysics,2014,35(6):1240-1243. [15] HATTA H, SOHTOME T, SAWADA Y, et al. High temperature crack sealant based on SiO2-B2O3 for SiC coating on carbon-carbon composites[J]. Advanced Composite Materials,2003,12(2/3):93-106. [16] 代廷魁. 改善高铝煤灰熔融特性及助熔机理研究[D]. 淮南: 安徽理工大学, 2016. [17] HUANG B Z, LAI J, HUANG B, et al. Experimental study on the effect to compressive strength of flux on sludge lightweight sintered shale brick[J]. Advanced Materials Research, 2013, 838/839/840/841: 2330-2333. [18] 马雯, 呼世斌.以城市污泥为掺料制备烧结砖[J]. 环境工程学报,2012,6(3):1035-1038.MA W, HU S B. Application of municipal sewage sludge in the process of sintering brick[J]. Chinese Journal of Environmental Engineering,2012,6(3):1035-1038. [19] 杨秀林. 含铬污泥制砖的实验研究[D]. 武汉: 武汉科技大学, 2015. [20] 裴会芳, 张长森, 陈景华.城市污泥-煤矸石-稻壳制备轻质烧结砖的研究[J]. 硅酸盐通报,2015,34(2):358-363. doi: 10.16552/j.cnki.issn1001-1625.2015.02.059PEI H F, ZHANG C S, CHEN J H. Preparation and property of light sintered brick with sewage sludge coal gangue and rice husk[J]. Bulletin of the Chinese Ceramic Society,2015,34(2):358-363. doi: 10.16552/j.cnki.issn1001-1625.2015.02.059 [21] HALL C, HAMILTON A. Porosity–density relations in stone and brick materials[J]. Materials and Structures,2015,48(5):1265-1271. □ doi: 10.1617/s11527-013-0231-1 -

下载:

下载: