Research on fluoride whole-process prevention and control in the electrolytic aluminum enterprise based on material flow analysis

-

摘要:

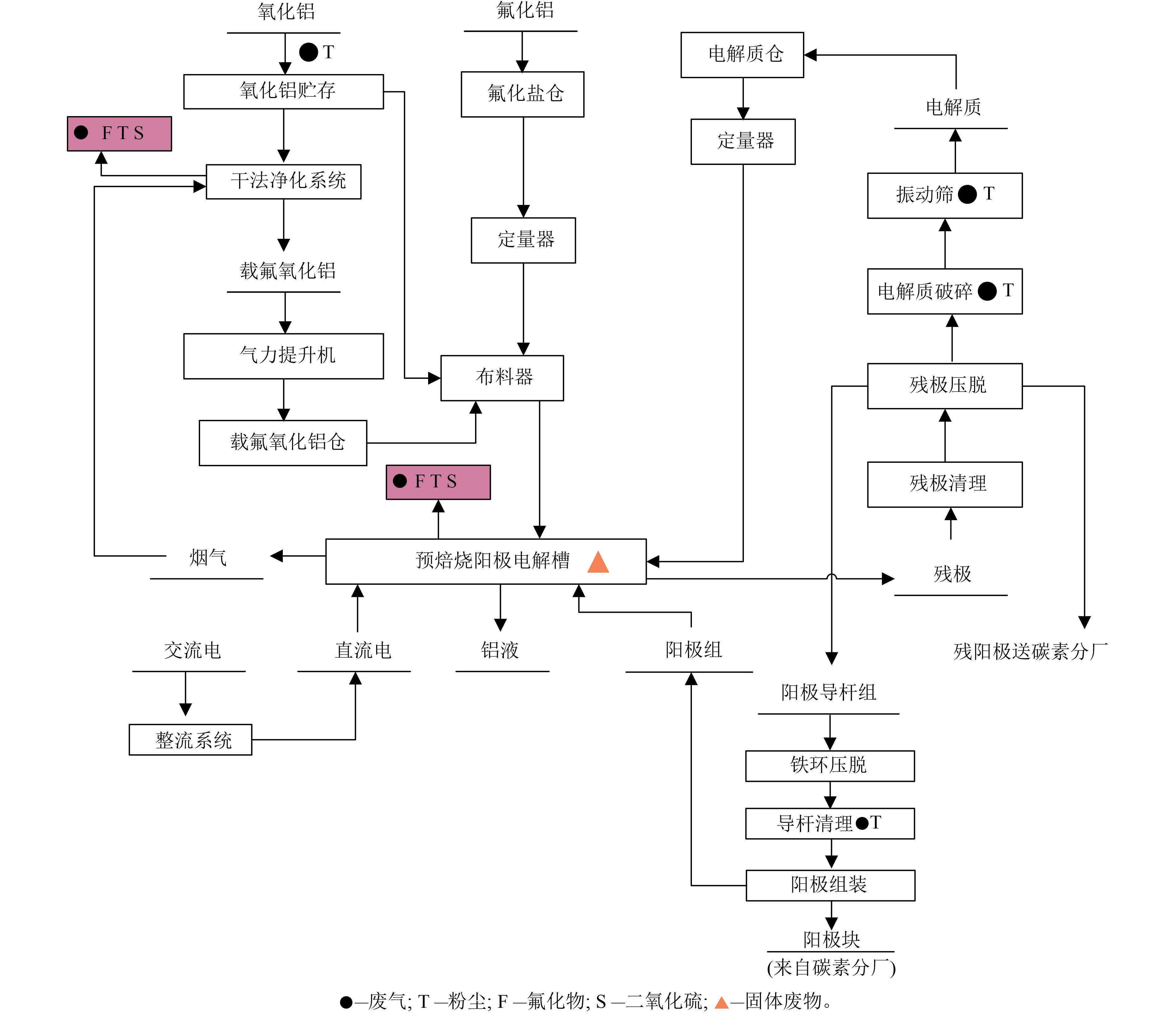

以国内某大型电解铝企业为例,针对氟化物产生的重点环节进行分析测试,通过物质流分析方法构建电解铝企业氟平衡,研究电解铝生产过程中特征污染物氟化物的分布特征。结果表明:除电解槽大修渣外,无组织烟气以及炭渣是电解铝生产过程中氟化物排放的关键环节,其中无组织烟气中氟化物含量折合单位产品排放量为0.374 kg/t (以Al质量计,全文同),约为有组织排放量的3.7倍;炭渣中氟化物含量为6.347 kg/t,约为大修渣中氟化物含量的2.7倍。为了加强电解铝行业氟化物风险防控,建议从生产全过程入手,通过提高电解槽的集气效率以及科学控制排烟量的方法有效控制无组织排放,优化电解槽排烟管道以提高有组织烟气治理的效率,控制原料含水量从源头减少氟化物的产生,强化含氟固体废物管控,以期减少电解铝企业对周边环境造成的氟污染。

Abstract:Taking a large domestic electrolytic aluminum enterprise as an example, the key links of fluoride production were analyzed and tested, the fluorine balance of the enterprise was constructed by material flow analysis method, and the distribution features of the characteristic pollutant fluoride in the electrolytic aluminum production process was studied. The results showed that apart from the overhaul slag of electrolytic cell, unorganized flue gas and carbon slag were the key points of fluoride emission in electrolytic aluminum production. The fluoride content of unorganized flue gas was 0.374 kg/t per unit product, which was about 3.7 times of that of organized emissions. The fluoride content in carbon slag was 6.347 kg/t, which was about 2.7 times of that in overhaul slag. In order to strengthen the fluoride risk prevention and control in the electrolytic aluminum industry, some suggestions were put forward starting from the whole production process, including effectively controlling the unorganized emissions by improving the gas collecting efficiency of electrolytic cells and controlling the smoke emissions scientifically, optimizing the smoke exhaust pipes of the electrolytic cells to improve the efficiency of organized flue gas treatment, controlling the water content of raw materials to reduce fluoride production at source, and strengthening the control of fluorine-containing solid wastes. Through these methods, the fluorine pollution caused by electrolytic aluminum enterprises to the surrounding environment could be reduced.

-

表 1 企业A电解车间氟平衡数据

Table 1. Fluorine balance data of electrolysis workshop of enterprise A

类别 名称 氟化物含量(以氟计)/(kg/t) 占比/% 来源/去向 输入 氟化铝 11.850 11.09 原料投入 冰晶石 1.220 1.14 原料投入 载氟氧化铝 17.506 16.39 干法净化 阳极破碎料 75.714 70.89 循环 铝包大修 0.038×10−2 <0.001 循环 铝包清包料 0.527 0.49 循环 合计 106.817 100.00 输出 炭渣 6.347 6.16 危废库 大修渣 2.357 2.29 危废库 阳极破碎料 75.714 73.53 循环 铝包大修 0.038×10−2 <0.001 循环 铝包清包料 0.527 0.51 循环 固定污染源 0.096 0.09 外排 载氟氧化铝 17.506 17.00 循环 脱硫石膏 0.045 0.04 处置 无组织排放 0.374 0.36 外排 合计 102.966 100.00 注:输入大于输出,存在一定的平衡误差,但在合理范围内。 -

[1] 中共中央 国务院 .中共中央 国务院关于深入打好污染防治攻坚战的意见. [2021-11-02]. http://www.gov.cn/zhengce/2021-11/07/content_5649656.htm. [2] 国家发展和改革委员会: 推动电解铝等重点行业绿色低碳转型[J]. 中国有色冶金, 2021, 50(5): 11. [3] 尹聚才.关于电解铝产业清洁生产的思考[J]. 中国金属通报,2020(9):12-13. doi: 10.3969/j.issn.1672-1667.2020.17.006YIN J C. Thoughts on cleaner production of electrolytic aluminum industry[J]. China Metal Bulletin,2020(9):12-13. doi: 10.3969/j.issn.1672-1667.2020.17.006 [4] 葛佳佳.碳中和背景下中国电解铝行业出口贸易问题及转型路径[J]. 对外经贸实务,2021(11):55-58. doi: 10.3969/j.issn.1003-5559.2021.11.012GE J J. Export trade problems and transformation path of electrolytic aluminum industry in China under the background of carbon neutralization[J]. Practice in Foreign Economic Relations and Trade,2021(11):55-58. doi: 10.3969/j.issn.1003-5559.2021.11.012 [5] 韩伟, 叶渊, 李彦希, 等.高氟地区电解铝厂场地氟污染特征及其风险评估[J]. 环境工程技术学报,2021,11(4):727-733. doi: 10.12153/j.issn.1674-991X.20200243HAN W, YE Y, LI Y X, et al. Fluorine pollution characteristics and risk assessment of electrolytic aluminum plant site in high fluoride area[J]. Journal of Environmental Engineering Technology,2021,11(4):727-733. doi: 10.12153/j.issn.1674-991X.20200243 [6] 唐剑, 陈湘清, 王波, 等.电解铝碳渣低温火法处理技术研究及应用[J]. 世界有色金属,2021(16):134-137. doi: 10.3969/j.issn.1002-5065.2021.16.060TANG J, CHEN X Q, WANG B, et al. Research and application of low temperature fire treatment technology for electrolytic aluminum carbon slag[J]. World Nonferrous Metals,2021(16):134-137. doi: 10.3969/j.issn.1002-5065.2021.16.060 [7] 郑丽英, 陈红辉, 张松柏, 等.从电解铝阴极炭块处理废水中回收冰晶石[J]. 电镀与涂饰,2021,40(11):889-892. doi: 10.19289/j.1004-227x.2021.11.014ZHENG L Y, CHEN H H, ZHANG S B, et al. Recovery of cryolite from the wastewater produced from the treatment of carbon block used as a cathode in aluminum electrolysis[J]. Electroplating & Finishing,2021,40(11):889-892. doi: 10.19289/j.1004-227x.2021.11.014 [8] 张乐.电解铝大修渣处理研究进展[J]. 世界有色金属,2021(4):154-155. doi: 10.3969/j.issn.1002-5065.2021.04.071ZHANG L. Research progress on treatment of electrolytic aluminum spent potlining[J]. World Nonferrous Metals,2021(4):154-155. doi: 10.3969/j.issn.1002-5065.2021.04.071 [9] 高宇.电解铝工业危废处置技术现状与发展趋势[J]. 有色冶金设计与研究,2019,40(4):33-35. doi: 10.3969/j.issn.1004-4345.2019.04.012GAO Y. Current situation and development trend of hazardous waste disposal technology in electrolytic aluminum industry[J]. Nonferrous Metals Engineering & Research,2019,40(4):33-35. doi: 10.3969/j.issn.1004-4345.2019.04.012 [10] 高康宁, 晁波阳, 申文斌, 等.电解铝厂大修渣污染分析与防治对策[J]. 资源节约与环保,2017(8):134. doi: 10.3969/j.issn.1673-2251.2017.08.074GAO K N, CHAO B Y, SHEN W B, et al. Pollution analysis and prevention countermeasures of overhaul slag in electrolytic aluminum plant[J]. Resources Economization & Environmental Protection,2017(8):134. doi: 10.3969/j.issn.1673-2251.2017.08.074 [11] WANG D Y, WANG H B, LI C L, et al. Process for stabilizing fluorine in electrolytic aluminum spent pot lining by roasting method[J]. IOP Conference Series:Earth and Environmental Science,2021,621(1):012036. doi: 10.1088/1755-1315/621/1/012036 [12] 张宏忠, 王利, 胡慧丽, 等.电解铝大修渣无害化处理研究[J]. 无机盐工业,2017,49(4):46-50.ZHANG H Z, WANG L, HU H L, et al. Harmless treatment of electrolytic aluminum residues[J]. Inorganic Chemicals Industry,2017,49(4):46-50. [13] 杜婷婷, 陈开斌, 孙丽贞, 等.铝电解大修渣处置技术探讨[J]. 世界有色金属,2020(1):14-15. doi: 10.3969/j.issn.1002-5065.2020.01.008DU T T, CHEN K B, SUN L Z, et al. Discussion on spent potlining disposal technology[J]. World Nonferrous Metals,2020(1):14-15. doi: 10.3969/j.issn.1002-5065.2020.01.008 [14] OSPINA G, HASSAN M I. Spent pot lining characterization framework[J]. JOM,2017,69(9):1639-1645. doi: 10.1007/s11837-017-2437-0 [15] 鞠昌华.避免先污染后治理的理论基础及其困境[J]. 鄱阳湖学刊,2017(1):83-89. doi: 10.3969/j.issn.1674-6848.2017.01.011JU C H. The theoretical basis and dilemma of avoiding “control after pollution”[J]. Journal of Poyang Lake,2017(1):83-89. doi: 10.3969/j.issn.1674-6848.2017.01.011 [16] 王天天, 卢笛音, 曹雅.物质流分析方法及应用研究综述[J]. 再生资源与循环经济,2017,10(8):9-12. doi: 10.3969/j.issn.1674-0912.2017.08.005WANG T T, LU D Y, CAO Y. A review of material flow analysis methods and application[J]. Recyclable Resources and Circular Economy,2017,10(8):9-12. doi: 10.3969/j.issn.1674-0912.2017.08.005 [17] 高昂. 循环经济物质流特征与流动规律研究[D]. 西安: 西北大学, 2010. [18] 傅泽强, 智静.物质代谢分析框架及其研究述评[J]. 环境科学研究,2010,23(8):1091-1098. doi: 10.13198/j.res.2010.08.116.fuzq.002FU Z Q, ZHI J. Review of and analytical framework for metabolism[J]. Research of Environmental Sciences,2010,23(8):1091-1098. doi: 10.13198/j.res.2010.08.116.fuzq.002 [19] 席冰冰. 基于物质流分析的区域循环经济评价体系研究: 以重庆市为例[D]. 重庆: 重庆大学, 2019. [20] AYRES R U, KNEESE A V. Production, consumption, and externalities[M]//The roots of logistics. Berlin, Heidelberg: Springer Berlin Heidelberg, 2012: 363-388. [21] UDO D H H, VOET E V D, KLEIJN R. Substance flow analysis (SFA), an analytical tool for integrated chain management[R]//BRINGEZU S, FISCHER-KOWALSKI M, KLEIJN R, et al. Regional and national material flow accounting: from paradigm to practice of sustainability. Bergisches Land, German: Wuppertal Institute for Climate, Environment and Energy, 1997: 32-42. [22] 刘毅. 中国磷代谢与水体富营养化控制政策研究[D]. 北京: 清华大学, 2004. [23] MA D C, HU S Y, CHEN D J, et al. Substance flow analysis as a tool for the elucidation of anthropogenic phosphorus metabolism in China[J]. Journal of Cleaner Production,2012,29/30:188-198. doi: 10.1016/j.jclepro.2012.01.033 [24] 杜春丽, 任雪莹, 杜子杰.基于元素流分析的长江经济带总磷污染减量化研究: 以湖北为例[J]. 中国环境管理,2021,13(3):136-145.DU C L, REN X Y, DU Z J. Research on the reduction of total phosphorus pollution in the Yangtze River Economic Zone based on substance flow analysis: take Hubei as an example[J]. Chinese Journal of Environmental Management,2021,13(3):136-145. [25] 党春阁, 周长波, 吴昊, 等.重金属元素物质流分析方法及案例分析[J]. 环境工程技术学报,2014,4(4):341-345. doi: 10.3969/j.issn.1674-991X.2014.04.055DANG C G, ZHOU C B, WU H, et al. Methods of substance flow analysis of heavy metal elements and case study[J]. Journal of Environmental Engineering Technology,2014,4(4):341-345. doi: 10.3969/j.issn.1674-991X.2014.04.055 [26] 白桦, 田金平, 李炳, 等.中国皮革行业铬元素代谢模型分析(续)[J]. 中国皮革,2018,47(12):21-27. doi: 10.13536/j.cnki.issn1001-6813.2018-012-004BAI H, TIAN J P, LI B, et al. Assessment of chromium metabolism in Chinese leather industry[J]. China Leather,2018,47(12):21-27. doi: 10.13536/j.cnki.issn1001-6813.2018-012-004 [27] 刘宏博, 郝雅琼, 吴昊, 等.铝冶炼行业危险废物产生和利用处置现状与管理对策建议[J]. 环境工程技术学报,2021,11(6):1273-1280. doi: 10.12153/j.issn.1674-991X.20210110LIU H B, HAO Y Q, WU H, et al. Present situation of production, utilization and disposal of hazardous waste in aluminium smelting industry and management countermeasures[J]. Journal of Environmental Engineering Technology,2021,11(6):1273-1280. doi: 10.12153/j.issn.1674-991X.20210110 [28] TONHEIM J, PAULSEN K A , HOLTEN R , et al. Environmental challenges in the prebake line at Hydro Aluminium Karmoy[C]//Light metals. Hydro Aluminium Karmoy, N-4265 Havik, Norway, 2005: 283-287. [29] 孙贵杰.数控脉冲管道清洗技术及应用[J]. 管道技术与设备,2020(2):9-10. doi: 10.3969/j.issn.1004-9614.2020.02.003SUN G J. NC pulse pipeline cleaning technology and application[J]. Pipeline Technique and Equipment,2020(2):9-10. doi: 10.3969/j.issn.1004-9614.2020.02.003 [30] 汪林.铝电解槽的氟平衡及降低氟排放的措施分析[J]. 轻金属,2018,475(5):21-25.

WANG L . An fluorine equilibrium of aluminum reduction pot and measures of reducing fluorine emission [J]. Light Metals,2018,475(5):21-25.[31] 李川, 李继涛, 任莉芳, 等.铝电解氟平衡及相关的氟化盐单耗[J]. 当代化工研究,2018(11):105-106. doi: 10.3969/j.issn.1672-8114.2018.11.060LI C, LI J T, REN L F, et al. Fluorine balance and related fluoride consumption per unit in aluminum electrolysis[J]. Modern Chemical Research,2018(11):105-106. ◇ doi: 10.3969/j.issn.1672-8114.2018.11.060 -

下载:

下载: