Technology development and engineering practice for emergency treatment of explosion pit wastewater in Xiangshui Chemical Industry Park explosion accident

-

摘要:

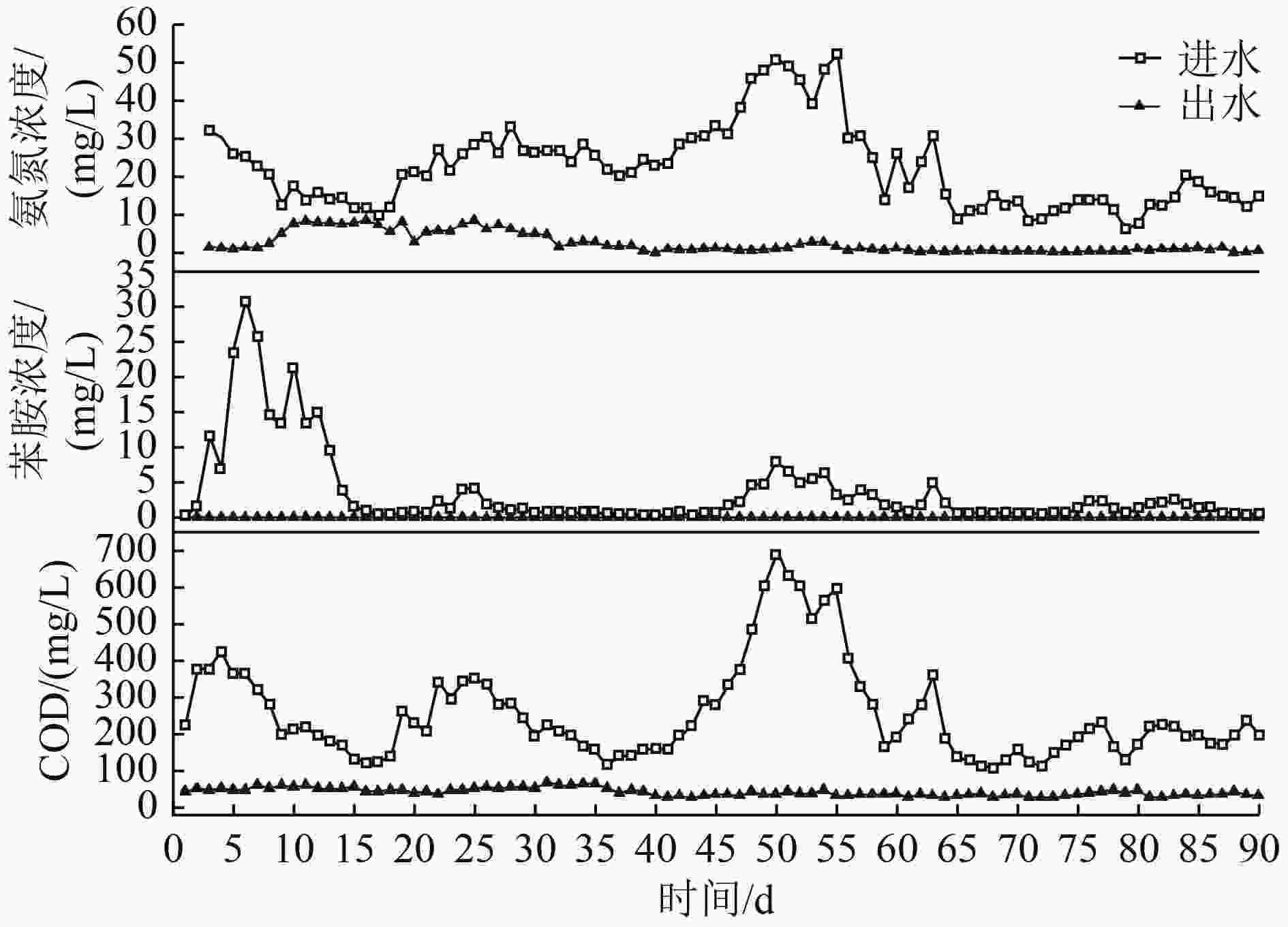

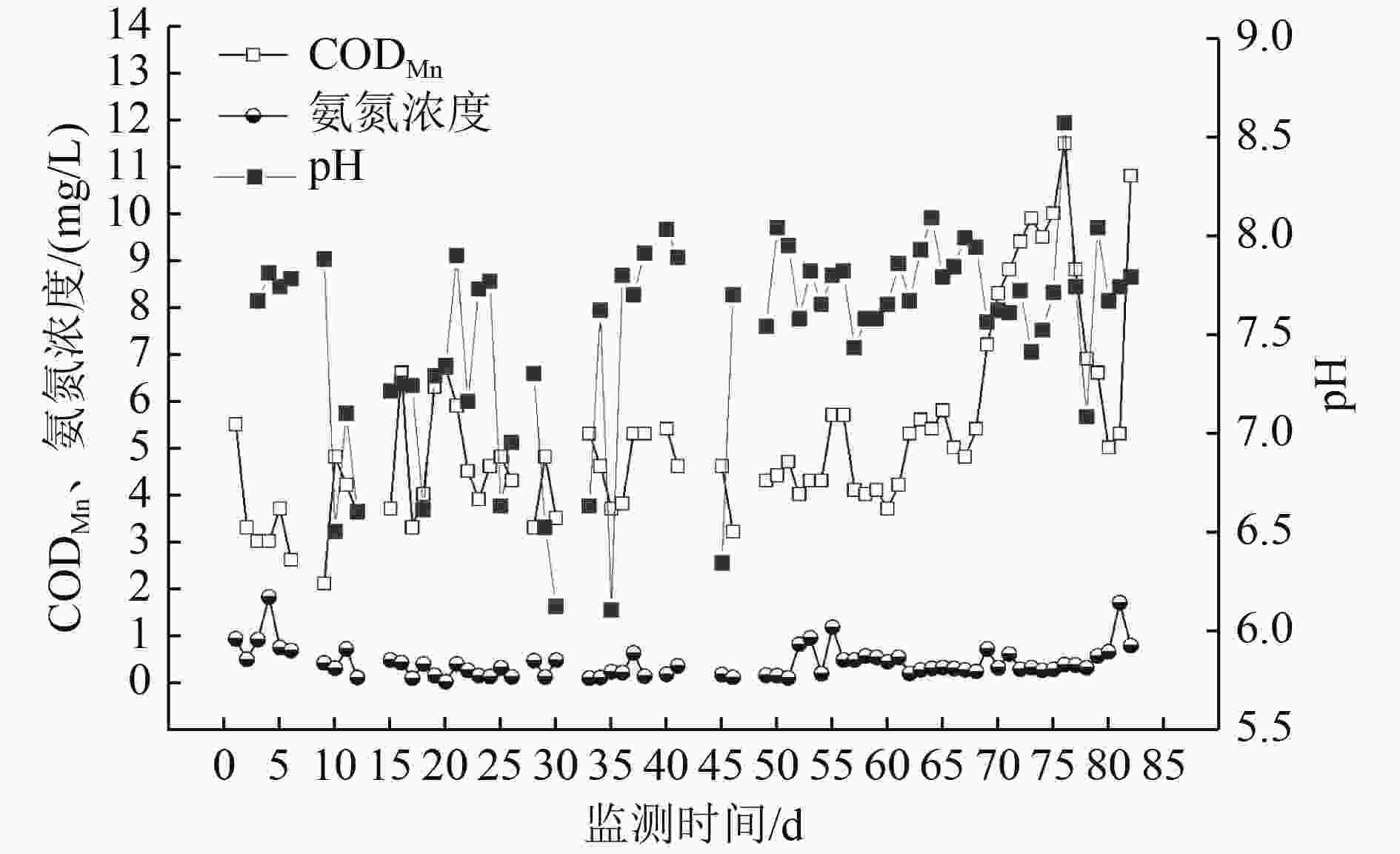

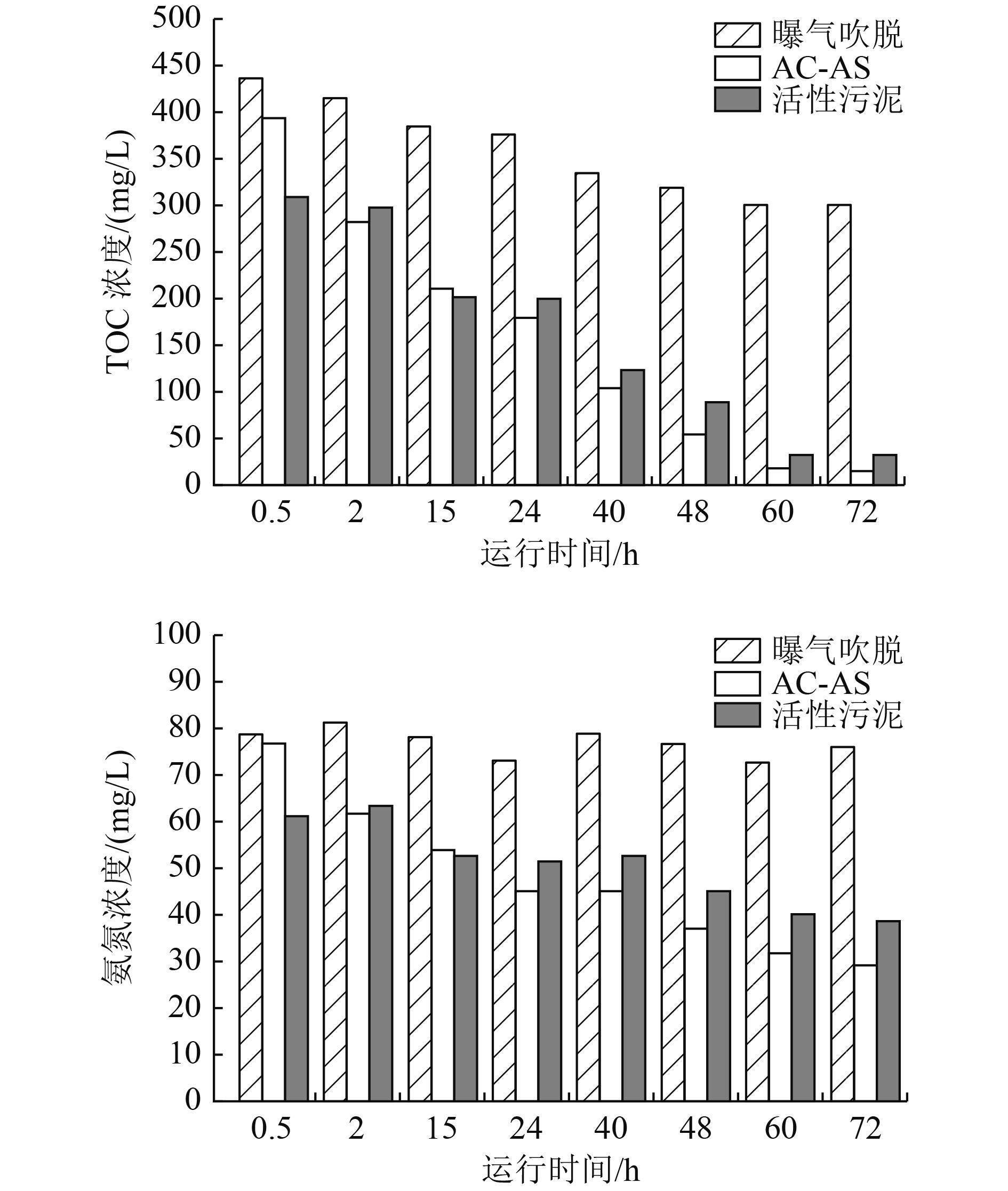

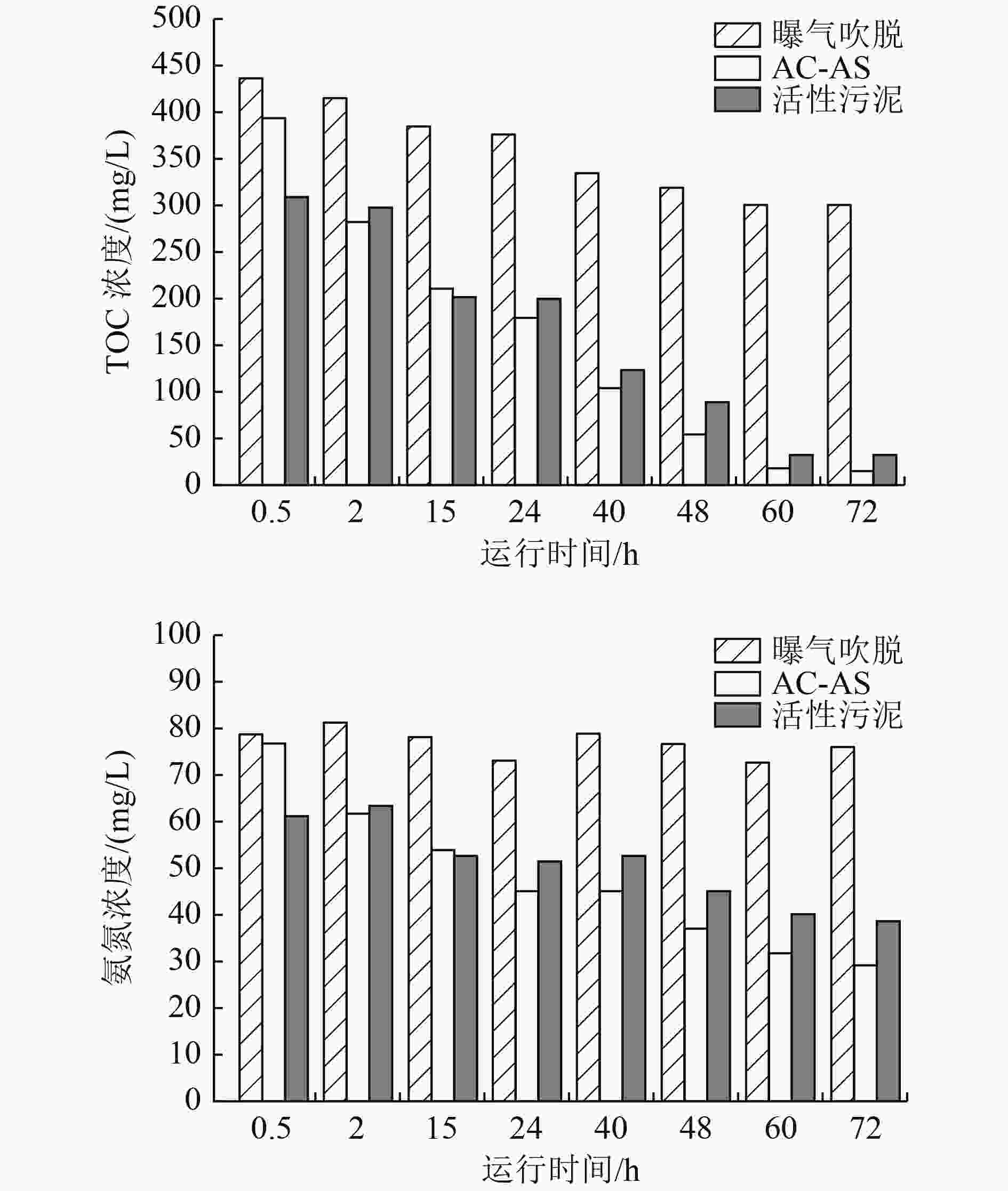

化工园区突发环境污染事故产生的污水具有污染物浓度高、毒性大、成分复杂、应急处理难度大等特点,对生态环境危害严重,且社会影响较大。针对响水化工园区爆炸事故爆坑污水应急处理需求,开展了污水水质分析、处理工艺筛选、小试试验验证以及工程实施成效研究。小试试验显示,采用活性炭-活性污泥(AC-AS)工艺对爆坑污水进行强化预处理,可大幅降低污水中污染物浓度,总有机碳和氨氮去除率达96.9%和65.7%,预处理后出水满足后续陈家港污水处理厂进水要求。工程运行结果显示,经AC-AS工艺预处理和陈家港污水处理厂处理后,出水COD、氨氮及其他污染物指标均满足污水处理厂执行的DB 32/939—2006《江苏省化学工业主要水污染物排放标准》和GB 31571—2015《石油化学工业污染物排放标准》,爆坑污水应急处理工程对COD、氨氮、苯胺累计削减量分别为33 319.6、209.4和6.2 kg。爆坑污水经陈家港污水处理厂达标处理排放后,受纳水体下游水质未出现异常,水环境未受到明显影响。此次污水处理案例表明,AC-AS工艺对该类事故污水具有较好的处理效果。

Abstract:The wastewater generated by the sudden environmental pollution accidents in the chemical parks has the characteristics of high concentration and toxicity, complex pollutant composition, and difficulty in emergency treatment, which is seriously harmful to the ecological environment and has a great social impact. In response to the needs of emergency treatment of wastewater from the explosion pit of Xiangshui Chemical Industry Park explosion accident, research on wastewater quality analysis, treatment process screening, bench-scale test, and project implementation effect was carried out. The bench-scale test showed that by the pretreatment of activated carbon enhanced activated sludge (AC-AS), the pollutant concentration of the explosion pit wastewater was greatly reduced, the removal efficiency of total organic carbon and ammonia nitrogen reached 96.9% and 65.7%, respectively, and the pretreated effluent met the influent requirements of the follow-up Chenjiagang Wastewater Treatment Plant (WTP). The project operation showed that after the pretreatment of AC-AS, and the treatment of WTP, all indicators of the effluent (COD, ammonia nitrogen and other pollutants) met the discharge standards of Discharge Standard of Main Water Pollutants for Chemical Industry of Jiangsu Province (DB 32/939-2006) and Emission Standard of Pollutants for Petrochemical Industry (GB 31571-2015). The emergency treatment project reduced chemical oxygen demand by 33319.6 kg, ammonia nitrogen by 209.4 kg, and aniline by 6.2 kg. After the wastewater was treated up to the discharge standard by Chenjiagang WTP, the water quality of the downstream receiving water body kept normal and the water environment was not significantly adversely affected. This wastewater treatment case showed that AC-AS had a good treatment effect on this kind of accidental wastewater.

-

Key words:

- Xiangshui /

- chemical industry park /

- explosion accident /

- wastewater /

- emergency treatment /

- engineering practice

-

表 1 受污染水量估算及水质指标

Table 1. Estimation of polluted water quantity and water quality indexes

受污染水体 pH COD/(mg/L) 氨氮浓度/(mg/L) 苯胺类浓度/(mg/L) 水质特征 预估水量/万m3 爆坑污水 9.1~12.5 1 300~3 000 50.0~90.0 高COD、高氨氮 2.1 厂区地面积水 <1.0 1 080~55 500 112.0~323.0 强酸性、高COD、高氨氮 0.1 三排河 6.1 634 10.0~15.0 50.0~80.0 高COD、高苯胺 2.8 新丰河重污染段 7.3 300~380 10.0 6.0~20.0 较高COD、高苯胺 2.2 新丰河轻污染段 7.2 79 3.1 0.9 轻度污染 2.2 新民支渠 7.0 468 7.8 0.9 高COD 3.5 新农河 8.2 93 2.5 轻度污染 0.7 四排河 6.0~9.0 64~315 3.2~39.0 0~13.1 轻度污染 0.8 新民河 6.0~9.0 23~114 0.02~1.5 0~0.08 微污染 14.3 总计 28.7 表 2 爆坑污水处理运行参数

Table 2. Operational parameters for wastewater treatment of explosion pit

指标 工程参数 处理水量/m3 20580 进水TOC浓度/(mg/L) <500.0 进水氨氮浓度/(mg/L) <40.0 pH 7.0~9.0 营养物质COD∶P 100∶1 活性炭投加量/(mg/L) 1 000 活性污泥浓度/(mg/L) 3 000 ~4 000 -

[1] 李亚男, 谭煜, 吴昌永, 等.臭氧催化氧化在石化废水深度处理应用中的若干问题[J]. 环境工程技术学报,2019,9(3):275-281. doi: 10.12153/j.issn.1674-991X.2019.02.280LI Y N, TAN Y, WU C Y, et al. Application and problems of catalytic ozonation in advanced treatment of petrochemical wastewater[J]. Journal of Environmental Engineering Technology,2019,9(3):275-281. doi: 10.12153/j.issn.1674-991X.2019.02.280 [2] 刘风华, 宋存义, 宋永会, 等.活性炭对含铜制药废水的吸附特性[J]. 环境科学研究,2011,24(3):308-312. doi: 10.13198/j.res.2011.03.72.liufh.010LIU F H, SONG C Y, SONG Y H, et al. Adsorption characteristics of Cu2+ from pharmaceutical wastewater onto activated carbon[J]. Research of Environmental Sciences,2011,24(3):308-312. doi: 10.13198/j.res.2011.03.72.liufh.010 [3] WEI J, SONG Y H, TU X, et al. Pretreatment of dry-spun acrylic fiber manufacturing wastewater by Fenton process: optimization, kinetics and mechanisms[J]. Chemical Engineering Journal,2013,218:319-326. doi: 10.1016/j.cej.2012.12.060 [4] ZHANG J L, XIONG Z K, WEI J, et al. Catalytic ozonation of penicillin G using cerium-loaded natural zeolite (CZ): efficacy, mechanisms, pathways and toxicity assessment[J]. Chemical Engineering Journal,2020,383:123144. doi: 10.1016/j.cej.2019.123144 [5] 魏健, 何锦垚, 宋永会, 等.臭氧催化氧化-BAF深度处理抗生素废水效能及微生物群落结构分析[J]. 环境科学学报,2020,40(6):2090-2100. doi: 10.13671/j.hjkxxb.2020.0025WEI J, HE J Y, SONG Y H, et al. Advanced treatment of antibiotic wastewater by catalytic ozonation combined with BAF process and an analysis of the bacterial community structures[J]. Acta Scientiae Circumstantiae,2020,40(6):2090-2100. doi: 10.13671/j.hjkxxb.2020.0025 [6] 杜松.SBR-电催化组合工艺处理己内酰胺废水试验研究[J]. 环境工程技术学报,2019,9(4):384-388. doi: 10.12153/j.issn.1674-991X.2019.03.260DU S. Treatment of organic pollutants in caprolactam wastewater by SBR and electrocatalytic oxidation combined process[J]. Journal of Environmental Engineering Technology,2019,9(4):384-388. doi: 10.12153/j.issn.1674-991X.2019.03.260 [7] 张立成, 牛艺, 宋永会, 等.低碳氮比条件下膜生物反应器处理高氨氮废水时稳定亚硝化过程的建立[J]. 环境工程技术学报,2014,4(6):451-455. doi: 10.3969/j.issn.1674-991X.2014.06.071ZHANG L C, NIU Y, SONG Y H, et al. Establishment of stable nitritation process in a MBR reactor for treatment of high ammonia wastewater with low C/N ratio[J]. Journal of Environmental Engineering Technology,2014,4(6):451-455. doi: 10.3969/j.issn.1674-991X.2014.06.071 [8] 王冠颖, 刘晓玲, 魏健, 等.响水化工园区爆炸事故污水应急预处理工艺筛选[J]. 环境科学学报,2020,40(12):4318-4324. doi: 10.13671/j.hjkxxb.2020.0252WANG G Y, LIU X L, WEI J, et al. Screening on emergency pretreatment process for accidental wastewater of explosion in Xiangshui Chemical Industry Park[J]. Acta Scientiae Circumstantiae,2020,40(12):4318-4324. doi: 10.13671/j.hjkxxb.2020.0252 [9] LU Z, SUN W, LI C, et al. Effect of granular activated carbon pore-size distribution on biological activated carbon filter performance[J]. Water Research,2020,177:115768. doi: 10.1016/j.watres.2020.115768 [10] 齐国远, 李翠梅, 张凯歌, 等.超滤组合工艺应急处理苯胺水源水污染研究[J]. 环境科学与技术,2017,40(11):109-113.QI G Y, LI C M, ZHANG K G, et al. Emergency treatment of aniline-polluted source water by integrated ultrafiltration technique: an experimental simulative study[J]. Environmental Science & Technology,2017,40(11):109-113. [11] BERTONE E, CHANG C, THIEL P, et al. Analysis and modelling of powdered activated carbon dosing for taste and odour removal[J]. Water Research,2018,139:321-328. doi: 10.1016/j.watres.2018.04.023 [12] LUO Y L, GUO W S, NGO H H, et al. A review on the occurrence of micropollutants in the aquatic environment and their fate and removal during wastewater treatment[J]. Science of the Total Environment,2014,473/474:619-641. doi: 10.1016/j.scitotenv.2013.12.065 [13] 王凯, 武道吉, 彭永臻, 等.垃圾渗滤液处理工艺研究及应用现状浅析[J]. 北京工业大学学报,2018,44(1):1-12. doi: 10.11936/bjutxb2017040036WANG K, WU D J, PENG Y Z, et al. Critical review of landfill leachate treatment technologies[J]. Journal of Beijing University of Technology,2018,44(1):1-12. doi: 10.11936/bjutxb2017040036 [14] LI S Y, FEI X N, CAO L Y, et al. Insights into the effects of carbon source on sequencing batch reactors: performance, quorum sensing and microbial community[J]. Science of the Total Environment,2019,691:799-809. doi: 10.1016/j.scitotenv.2019.07.191 [15] 吴聪慧, 王彬浩, 虞奕丹, 等.氟化工废水处理系统中活性污泥的耐毒性及微生物群落结构特征分析[J]. 环境科学学报,2017,37(3):962-970. doi: 10.13671/j.hjkxxb.2016.0335WU C H, WANG B H, YU Y D, et al. Tolerance abilities and microbial community characteristics of activated sludges in fluoride wastewater treatment plants[J]. Acta Scientiae Circumstantiae,2017,37(3):962-970. doi: 10.13671/j.hjkxxb.2016.0335 [16] JIA S Y, HAN H J, HOU B L, et al. Treatment of coal gasification wastewater by membrane bioreactor hybrid powdered activated carbon (MBR-PAC) system[J]. Chemosphere,2014,117:753-759. doi: 10.1016/j.chemosphere.2014.09.085 [17] YU Z Z, HU Y S, DZAKPASU M, et al. Dynamic membrane bioreactor performance enhancement by powdered activated carbon addition: evaluation of sludge morphological, aggregative and microbial properties[J]. Journal of Environmental Sciences,2019,75:73-83. doi: 10.1016/j.jes.2018.03.003 [18] AGHAMOHAMMADI N, AZIZ H B A, ISA M H, et al. Powdered activated carbon augmented activated sludge process for treatment of semi-aerobic landfill leachate using response surface methodology[J]. Bioresource Technology,2007,98(18):3570-3578. doi: 10.1016/j.biortech.2006.11.037 [19] AZIZ S Q, AZIZ H A, YUSOFF M S, et al. Landfill leachate treatment using powdered activated carbon augmented sequencing batch reactor (SBR) process: optimization by response surface methodology[J]. Journal of Hazardous Materials,2011,189(1/2):404-413. [20] DITTMANN D, BRAUN U, JEKEL M, et al. Quantification and characterisation of activated carbon in activated sludge by thermogravimetric and evolved gas analyses[J]. Journal of Environmental Chemical Engineering,2018,6(2):2222-2231. doi: 10.1016/j.jece.2018.03.010 [21] LIN H J, WANG F Y, DING L X, et al. Enhanced performance of a submerged membrane bioreactor with powdered activated carbon addition for municipal secondary effluent treatment[J]. Journal of Hazardous Materials,2011,192(3):1509-1514. doi: 10.1016/j.jhazmat.2011.06.071 [22] 张龙, 涂勇, 吴伟, 等.生物活性炭(PACT)对印染废水A2/O工艺强化运行效果的表征[J]. 环境科学学报,2014,34(3):664-670.ZHANG L, TU Y, WU W, et al. Characterization of improved performance by powdered active carbon treatment (PACT) for dyeing wastewater treatment using A2/O process[J]. Acta Scientiae Circumstantiae,2014,34(3):664-670. [23] 吴伟, 张龙, 刘伟京, 等.PACT工艺系统中的吸附和生物降解性能研究[J]. 环境科学研究,2010,23(8):1062-1067. doi: 10.13198/j.res.2010.08.87.wuw.013WU W, ZHANG L, LIU W J, et al. Adsorption and biodegradation effects in PACT process systems[J]. Research of Environmental Sciences,2010,23(8):1062-1067. doi: 10.13198/j.res.2010.08.87.wuw.013 [24] 刘皓月, 王磊, 吕永涛, 等.微生物絮凝剂与聚合氯化铝复配处理污水厂二级出水[J]. 环境工程学报,2017,11(1):111-115. doi: 10.12030/j.cjee.201509134LIU H Y, WANG L, LYU Y T, et al. Combination of bioflocculant and PAC for treatment of secondary effluent in a wastewater treatment plant[J]. Chinese Journal of Environmental Engineering,2017,11(1):111-115. doi: 10.12030/j.cjee.201509134 [25] CAREY R O, MIGLIACCIO K W. Contribution of wastewater treatment plant effluents to nutrient dynamics in aquatic systems: a review[J]. Environmental Management,2009,44(2):205-217. ⊗ doi: 10.1007/s00267-009-9309-5 -

下载:

下载: