Experimental study on gas-liquid mixing and foaming characteristics of Venturi series bubble generator

-

摘要:

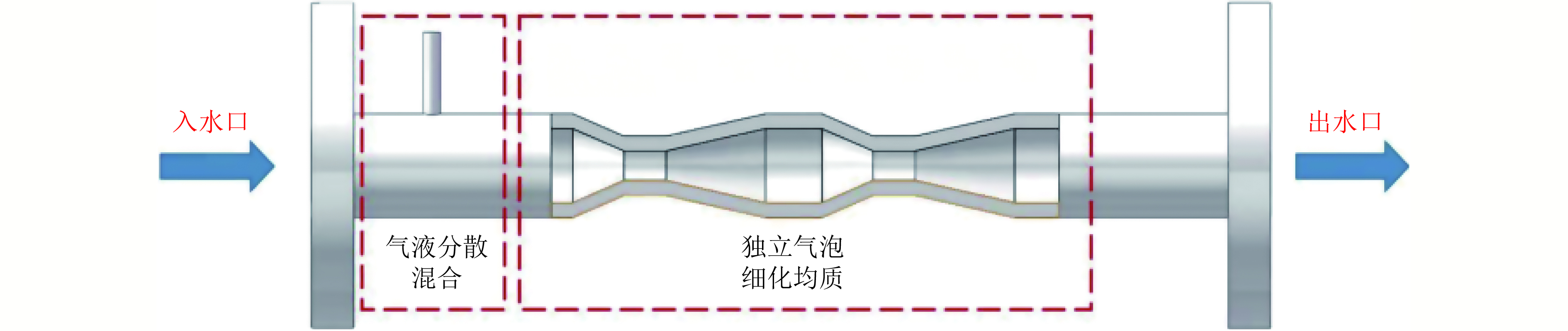

高效紧凑型微细气泡发生技术和粒径调控技术是微细气泡技术大规模工业应用的前提和基础。通过CFD数值模拟手段和试验测试手段测试两级文丘里串联结构气泡发生器内气液两相混合发泡特性,并利用响应曲面法对关键结构参数进行了优化设计和交互影响分析。结果表明:对两级文丘里串联结构气泡发生器成泡粒径影响最大的参数主要是二级喉管管径,其次为一级喉管管径和二级扩张角,一级扩张角的影响最小。相同工况条件下,单级文丘里管气泡发生器所生成的气泡群中位粒径为543.64 μm,粒径小于100 μm的微细气泡数量占比为8.6%;两级文丘里管串联气泡发生器所生成的气泡中位粒径为515.99 μm,微细气泡数量占比提升至12.1%。因此,可以通过控制水流流量和改变文丘里串联数量实现气泡粒径从毫米级别到微米级别的调控。

Abstract:The efficient and compact microbubble generation technology and particle size control technology are the premise and foundation of large-scale industrial application of microbubble technology. The foaming characteristics of gas-liquid two-phase mixing in two-stage Venturi series bubble generator were studied employing CFD numerical simulation and experimental test, the key structural parameters were optimized, and the interactions were analyzed by Response Surface Method. The results showed that the diameter of the throat in the second stage had the greatest influence on the bubble particle size of the two-stage Venturi series bubble generator, followed by the diameter of the throat in the first stage and the second stage expansion angle, while the expansion angle in the first stage had the least influence. Under the same working conditions, the median particle size of bubbles generated by single-stage Venturi bubble generator was 543.64 μm, and the proportion of fine bubbles with particle size less than 100 μm was 8.6%. The median particle size of bubbles generated by two-stage Venturi series bubble generator was 515.99 μm, and the proportion of fine bubbles increased to 12.1%. Thus by controlling the flow rate and changing the number of Venturis in series, the bubble particle size could be adjusted from millimeter level to micron level.

-

Key words:

- fine bubble /

- Venturi /

- CFD numerical simulation /

- response surface method /

- bubble characteristics

-

表 1 两级文丘里串联结构气泡发生器关键结构参数尺寸

Table 1. Dimensions of key structural parameters of two-stage Venturi series bubble generator

主要参数 尺寸 主要参数 尺寸 入水口管径/mm 25 注气口直径/mm 8 喉管直径/mm 10 收缩管段角度/(°) 22.5 扩散管段角度/(°) 12 外壁厚度/mm 0.277 表 2 响应曲面法模拟因子和水平

Table 2. Simulation factors and levels of response surface methodology

因子 水平 1 0 −1 一级喉管管径/mm 13 9 5 一级扩张角/(°) 15 11 7 二级喉管管径/mm 13 9 5 二级扩张角/(°) 15 11 7 -

[1] 李兆军, 杜浩.我国微泡技术发展综述[J]. 过程工程学报,2017,17(4):655-663. doi: 10.12034/j.issn.1009-606X.216346LI Z J, DU H. Review of the development of fine bubble technology in China[J]. The Chinese Journal of Process Engineering,2017,17(4):655-663. doi: 10.12034/j.issn.1009-606X.216346 [2] 谢冰琪, 周才金, 黄小婷, 等.微分散法连续制备微气泡的研究进展[J]. 过程工程学报,2021,21(8):865-876. doi: 10.12034/j.issn.1009-606X.220341XIE B Q, ZHOU C J, HUANG X T, et al. Research progress of continuous generation of microbubbles by microdispersion[J]. The Chinese Journal of Process Engineering,2021,21(8):865-876. doi: 10.12034/j.issn.1009-606X.220341 [3] 熊永磊, 杨小丽, 宋海亮.微纳米气泡在水处理中的应用及其发生装置研究[J]. 环境工程,2016,34(6):23-27.XIONG Y L, YANG X L, SONG H L. Review on application of micro-nano bubble in water treatment and its generator[J]. Environmental Engineering,2016,34(6):23-27. [4] 吴娜, 薛晓莉, 张志立, 等.微纳米气泡技术在环保领域的应用研究进展[J]. 现代农业科技,2020(17):154-155. doi: 10.3969/j.issn.1007-5739.2020.17.096WU N, XUE X L, ZHANG Z L, et al. Research progress on application of micro nano bubble technology in environmental protection field[J]. Modern Agricultural Science and Technology,2020(17):154-155. doi: 10.3969/j.issn.1007-5739.2020.17.096 [5] 田立平, 鞠玲, 王晓波, 等.微纳米气泡制备技术及应用研究[J]. 能源与环境,2020(4):69-73. [6] USHIKUBO F Y, FURUKAWA T, NAKAGAWA R, et al. Evidence of the existence and the stability of nano-bubbles in water[J]. Colloids and Surfaces A:Physicochemical and Engineering Aspects,2010,361(1/2/3):31-37. [7] 郑秋生.微气泡旋流气浮选设备的研究与应用[J]. 油气田环境保护,2015,25(4):36-38. doi: 10.3969/j.issn.1005-3158.2015.04.012ZHENG Q S. Research and application of the microbubble swirling air flotation equipment[J]. Environmental Protection of Oil & Gas Fields,2015,25(4):36-38. doi: 10.3969/j.issn.1005-3158.2015.04.012 [8] 杨涛, 李浙昆, 张永忍, 等.旋流式微泡发生器的设计与试验研究[J]. 水利水电技术,2016,47(5):141-144.YANG T, LI Z K, ZHANG Y R, et al. Design and experimental study of rotational-flow micro-bubble generator[J]. Water Resources and Hydropower Engineering,2016,47(5):141-144. [9] 高兴斋, 刘育禾, 钟巧云, 等.用物化法处理卷烟厂综合废水的实践[J]. 环境科学研究,1998,11(5):55-57. doi: 10.3321/j.issn:1001-6929.1998.05.020GAO X Z, LIU Y H, ZHONG Q Y, et al. Practice of wastewater treatment in cigarette plant using physico-chemical process[J]. Research of Environmental Sciences,1998,11(5):55-57. doi: 10.3321/j.issn:1001-6929.1998.05.020 [10] 吕奉祥, 初里冰, 周军, 等.新型微米曝气设备的研制及其性能[J]. 化工学报,2011,62(6):1537-1542. doi: 10.3969/j.issn.0438-1157.2011.06.009LÜ F X, CHU L B, ZHOU J, et al. Development of a new microbubble system and its performance[J]. CIESC Journal,2011,62(6):1537-1542. doi: 10.3969/j.issn.0438-1157.2011.06.009 [11] 杨丽, 廖传华, 朱跃钊, 等.微纳米气泡特性及在环境污染控制中的应用[J]. 化工进展,2012,31(6):1333-1337.YANG L, LIAO C H, ZHU Y Z, et al. Characteristics of micro-bubble and nano-bubble and their application in environmental pollution control[J]. Chemical Industry and Engineering Progress,2012,31(6):1333-1337. [12] 刘秋菊, 熊若晗, 宋艳芳, 等.微纳米气泡在环境污染控制领域的应用[J]. 环境与可持续发展,2017,42(3):100-102. doi: 10.3969/j.issn.1673-288X.2017.03.026LIU Q J, XIONG R H, SONG Y F, et al. The application of micro-nano bubble in environmental pollution control[J]. Environment and Sustainable Development,2017,42(3):100-102. doi: 10.3969/j.issn.1673-288X.2017.03.026 [13] OKAMOTO K, HOTTA K, TOYAMA T, et al. Experiments on purification of ocean sludge by activating microorganisms[C]// International Society of Offshore and Polar Engineers. Hawaii, 2011. [14] PARK Y, KIM H, KIM J, et al. Measurement of liquid-vapor phase distribution on nano- and microstructured boiling surfaces[J]. International Journal of Multiphase Flow,2016,81:67-76. doi: 10.1016/j.ijmultiphaseflow.2016.01.007 [15] 魏小林, 杨仓海, 李永长.一种高效溶气释放器的研制及应用[J]. 化工管理,2019(31):89-90.WEI X L, YANG C H, LI Y C. Development and application of a high efficiency dissolved air releaser[J]. Chemical Enterprise Management,2019(31):89-90. [16] 赵鹏, 方全利, 陈宝锋.加压溶气气浮设备结构与工艺技术研究现状[J]. 中国化工装备,2015,17(4):7-9. doi: 10.3969/j.issn.1671-0525.2015.04.002ZHAO P, FANG Q L, CHEN B F. Structure and processes technique research status of dissolved air floatation equipment[J]. China Chemical Industry Equipment,2015,17(4):7-9. doi: 10.3969/j.issn.1671-0525.2015.04.002 [17] 李强, 张健, 张凤超, 等. 一种微纳米气泡发生器: CN111569684A[P]. 2020-08-25. [18] 唐文偲, 阎昌琪, 孙立成, 等.文丘里式气泡发生器气泡碎化特性研究[J]. 原子能科学技术,2014,48(5):844-848. doi: 10.7538/yzk.2014.48.05.0844TANG W C, YAN C Q, SUN L C, et al. Characteristic of bubble breakup in Venturi-type bubble generator[J]. Atomic Energy Science and Technology,2014,48(5):844-848. doi: 10.7538/yzk.2014.48.05.0844 [19] 王永磊, 王文浩, 代莎莎, 等.微纳米气泡发生机理及其应用研究进展[J]. 山东建筑大学学报,2017,32(5):474-480.WANG Y L, WANG W H, DAI S S, et al. Research progress of mechanism and application of micro and nano bubble[J]. Journal of Shandong Jianzhu University,2017,32(5):474-480. [20] 邓超, 杨丽, 陈海军, 等.微纳米气泡发生装置及其应用的研究进展[J]. 石油化工,2014,43(10):1206-1213. doi: 10.3969/j.issn.1000-8144.2014.10.018DENG C, YANG L, CHEN H J, et al. Progresses in research and application of micro-nano bubble generating device[J]. Petrochemical Technology,2014,43(10):1206-1213. doi: 10.3969/j.issn.1000-8144.2014.10.018 [21] FUJIWARA A, OKAMOTO K, HASHIGUCHI K, et al. Bubble breakup phenomena in a Venturi tube[C]//Proceedings of ASME/JSME 2007 5th Joint Fluids Engineering Conference. San Diego, 2009: 553-560. [22] HUANG J, SUN L C, MO Z Y, et al. Experimental investigation on the effect of throat size on bubble transportation and breakup in small Venturi channels[J]. International Journal of Multiphase Flow,2021,142:103737. doi: 10.1016/j.ijmultiphaseflow.2021.103737 [23] MURAI Y, TASAKA Y, OISHI Y, et al. Bubble fragmentation dynamics in a subsonic Venturi tube for the design of a compact microbubble generator[J]. International Journal of Multiphase Flow,2021,139:103645. doi: 10.1016/j.ijmultiphaseflow.2021.103645 [24] 王德忠, 宋煜晨, 申屠云奇, 等. 多级台阶型文丘里式气泡发生装置: CN111348711A[P]. 2020-06-30. [25] 申屠云奇, 宋煜晨, 尹俊连, 等.扩散角对文丘里管内湍流影响的试验研究[J]. 核动力工程,2021,42(2):16-22.SHENTU Y Q, SONG Y C, YIN J L, et al. Experimental study on effect of diffusion angle on turbulence in Venturi tube[J]. Nuclear Power Engineering,2021,42(2):16-22. [26] ABBAS-SHIROODI Z, SADEGHI M T, BARADARAN S. Design and optimization of a cavitating device for Congo red decolorization: experimental investigation and CFD simulation[J]. Ultrasonics Sonochemistry,2021,71:105386. doi: 10.1016/j.ultsonch.2020.105386 [27] SAYYAADI H. Assessment of tandem Venturi on enhancement of cavitational chemical reaction[J]. Journal of Fluids Engineering,2009,131(1):011301. doi: 10.1115/1.3026731 [28] SAYYAADI H. Instability of the cavitating flow in a Venturi reactor[J]. Fluid Dynamics Research,2010,42(5):055503. doi: 10.1088/0169-5983/42/5/055503 [29] VASILEV M P, ABIEV R S. Dispersion of carbon nanotubes clusters in pulsating and vortex in-line apparatuses[J]. Chemical Engineering Science,2017,171:204-217. doi: 10.1016/j.ces.2017.05.036 [30] VASILEV M P, ABIEV R S. Turbulent droplets dispersion in a pulsating flow type apparatus: new type of static disperser[J]. Chemical Engineering Journal,2018,349:646-661. doi: 10.1016/j.cej.2018.05.104 [31] VASILEV M P, ABIEV R S. Intensity and efficiency of droplet dispersion: pulsating flow type apparatus vs. static mixers[J]. Chemical Engineering Research and Design,2018,137:329-349. doi: 10.1016/j.cherd.2018.07.029 [32] 赵梁, 孙立成, 莫政宇, 等. 一种多文丘里结构的文丘里式气泡发生装置: CN109433035A[P]. 2019-03-08. [33] 韩桂华, 杨旭东, 陈德裕, 等.探究串联文丘里管空化特性[J]. 哈尔滨理工大学学报,2022(2):55-62. doi: 10.15938/j.jhust.2022.02.007HAN G H, YANG X D, CHEN D Y, et al. Research on cavitation characteristics of series Venturi[J]. Journal of Harbin University of Science and Technology,2022(2):55-62. doi: 10.15938/j.jhust.2022.02.007 [34] 李文杰.化学制药企业废水处理工程实例[J]. 环境工程技术学报,2020,10(4):606-612. doi: 10.12153/j.issn.1674-991X.20200074LI W J. An example of wastewater treatment project in a chemical pharmaceutical enterprise[J]. Journal of Environmental Engineering Technology,2020,10(4):606-612. doi: 10.12153/j.issn.1674-991X.20200074 [35] 徐峰, 黄海, 杨勇, 等.挥发性有机物污染地下水吹脱处理的中小试研究[J]. 环境工程技术学报,2017,7(4):457-462. doi: 10.3969/j.issn.1674-991X.2017.04.062XU F, HUANG H, YANG Y, et al. Lab and pilot study on treatment of volatile organic compounds contaminated underground water with air stripping method[J]. Journal of Environmental Engineering Technology,2017,7(4):457-462. doi: 10.3969/j.issn.1674-991X.2017.04.062 [36] JIANG X, YASUNOBU T, NAKAMURA A, et al. Miniaturization of bubbles by shock waves in gas-liquid two-phase flow in the Venturi tube[J]. Journal of Thermal Science,2021,30(3):1068-1076. doi: 10.1007/s11630-021-1432-5 [37] 赵梁, 杜敏, 莫政宇, 等.文丘里式气泡发生器渐扩段内单气泡输运过程研究[J]. 原子能科学技术,2019,53(6):1021-1028. doi: 10.7538/yzk.2018.youxian.0537ZHAO L, DU M, MO Z Y, et al. Transportation of individual bubble in diverging section of Venturi-type bubble generator[J]. Atomic Energy Science and Technology,2019,53(6):1021-1028. doi: 10.7538/yzk.2018.youxian.0537 [38] 邓仁健, 唐智娥, 任伯帜, 等.响应曲面法优化Fe(Ⅲ)改性卡氏变形杆菌吸附去除Sb(Ⅴ)及其机理[J]. 环境科学研究,2020,33(12):2888-2897.DENG R J, TANG Z E, REN B Z, et al. Optimization and mechanism of Sb(Ⅴ) removal from aqueous solution by Fe(Ⅲ) modified proteus cibarius with response surface methodology[J]. Research of Environmental Sciences,2020,33(12):2888-2897. [39] WU H T, XU Y, WANG J H, et al. Gas-liquid two-phase flowrate measurement in pseudo-slug flow with Venturi[J]. Flow Measurement and Instrumentation,2021,78:101887. doi: 10.1016/j.flowmeasinst.2021.101887 [40] DENG R, HU K, LIANG D, et al. Simulation and analysis of dual Venturi multiphase flowmeter[J]. Scientific Journal of Intelligent Systems Research,2021,3(3):219-226. [41] SOUBIRAN J, SHERWOOD J D. Bubble motion in a potential flow within a Venturi[J]. International Journal of Multiphase Flow,2000,26(11):1771-1796. doi: 10.1016/S0301-9322(99)00113-5 [42] 刘桂凤. 涡流空气分级机内气流及气固两相流的数值模拟研究[D]. 北京: 北京化工大学, 2011. [43] 秦金为, 周骛, 蔡小舒, 等.自洁式餐饮油烟颗粒物浓度测量管段设计及影响因素分析[J]. 环境工程技术学报,2020,10(2):183-191. doi: 10.12153/j.issn.1674-991X.20190107QIN J W, ZHOU W, CAI X S, et al. Design of self-cleaning pipe segment for concentration measurement of cooking fume particulate matter and analysis of influencing factors[J]. Journal of Environmental Engineering Technology,2020,10(2):183-191. doi: 10.12153/j.issn.1674-991X.20190107 [44] 李浩, 韩启彪, 黄修桥, 等.基于多孔介质模型下微灌网式过滤器CFD湍流模型选择及流场分析[J]. 灌溉排水学报,2016,35(4):14-19.LI H, HAN Q B, HUANG X Q, et al. Turbulence model selection and flow field analysis of the micro irrigation screen filter based on porous medium using CFD[J]. Journal of Irrigation and Drainage,2016,35(4):14-19. [45] HINZE J. Fundamentals of hydrodynamic mechanism of splitting in dispersion processes[J]. AICHE,1955,1:289-295. doi: 10.1002/aic.690010303 [46] MARTINEZ-BAZAN C, LASHERAS J C. Turbulent dispersion of bubbles in a plane, free shear layer[J]. Experimental Thermal and Fluid Science,2001,25:437-445. □ doi: 10.1016/S0894-1777(01)00097-8 -

下载:

下载: