Study on deep dewatering and heavy metal stabilization of stocked sludge

-

摘要:

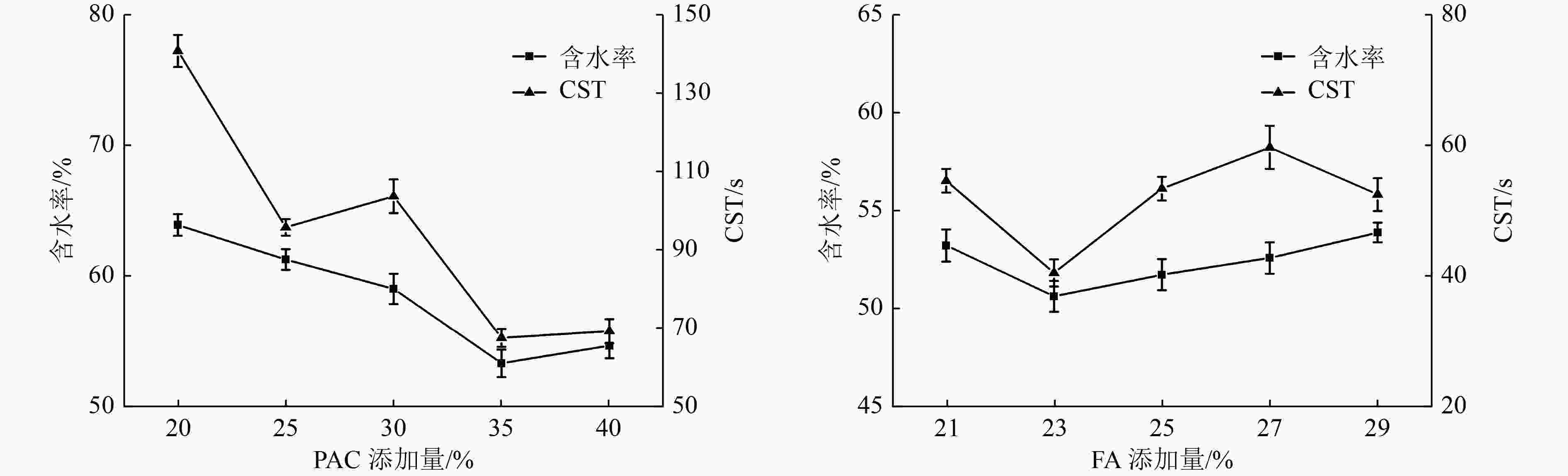

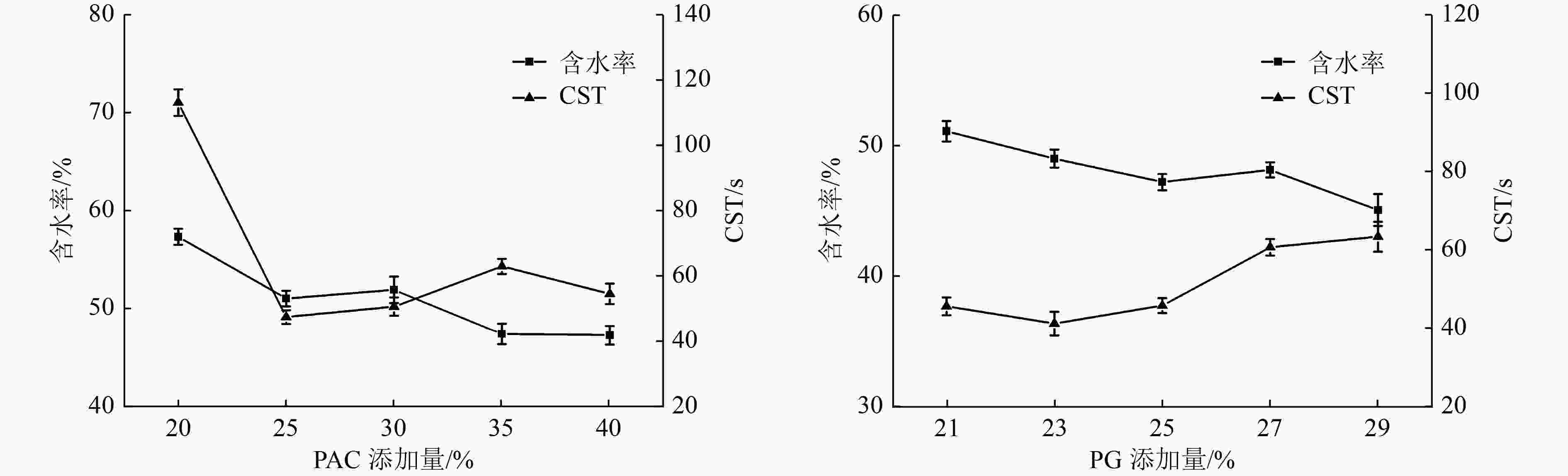

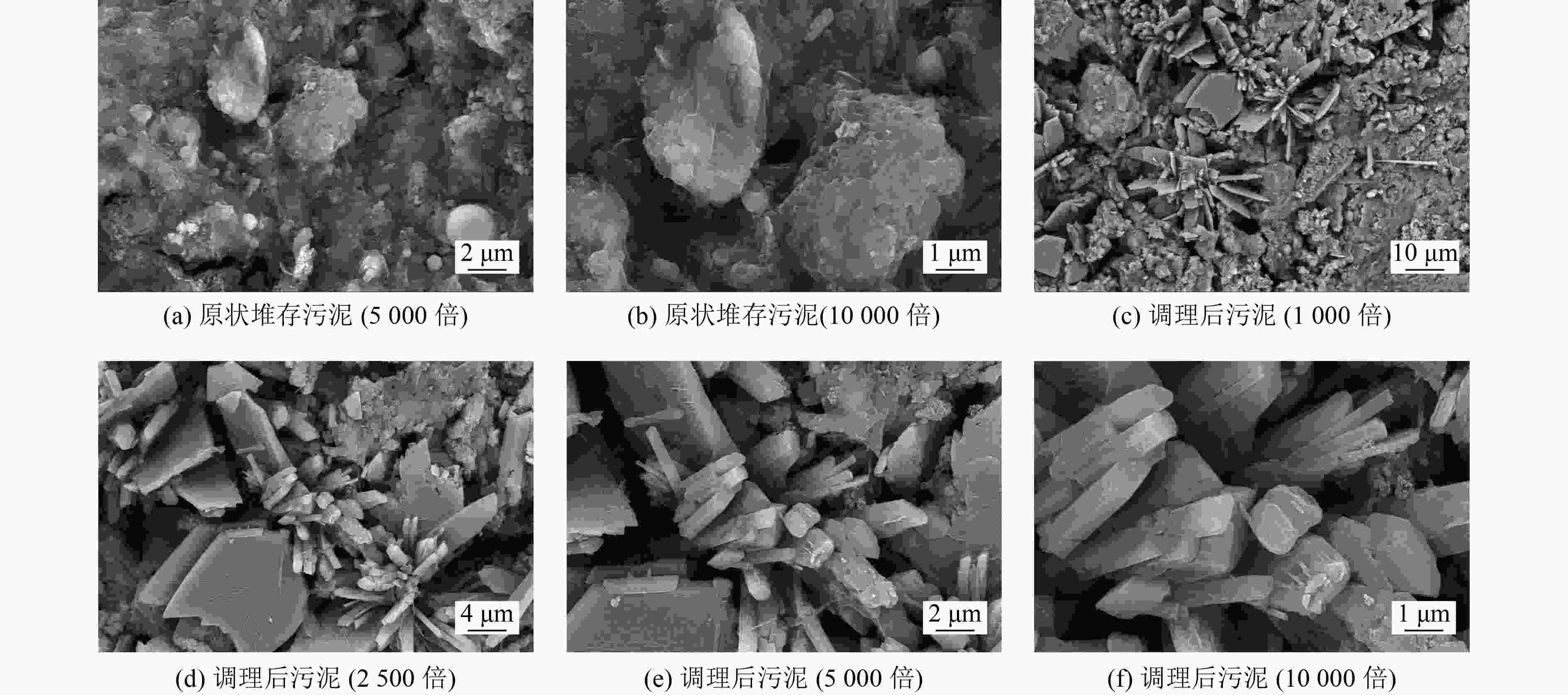

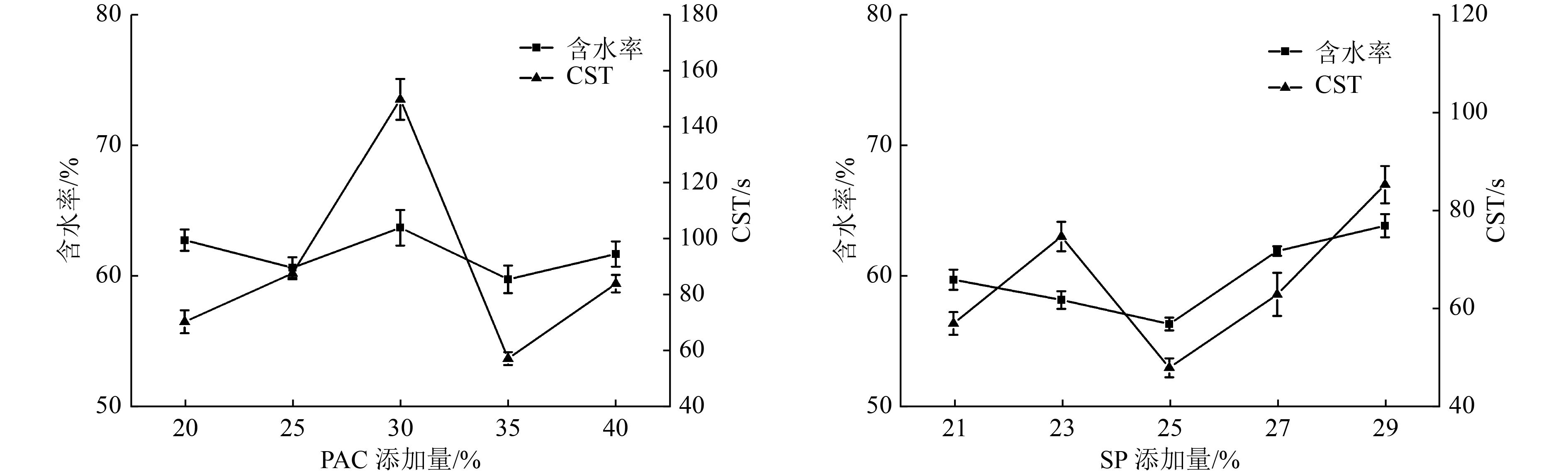

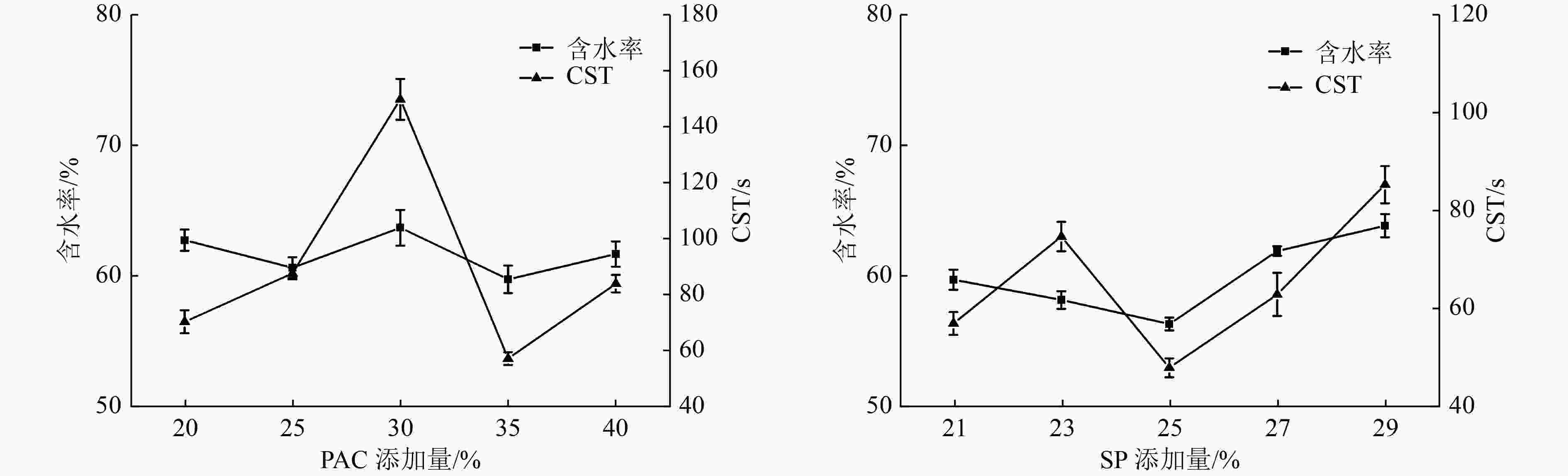

堆存污泥具有高含水率和潜在重金属污染特征,对堆存填埋场及周边环境可能产生潜在生态风险。以秸秆(SP)、粉煤灰(FA)、磷石膏(PG)3种固体废物材料搭配2种常用脱水剂氧化钙(CaO)、聚合氯化铝(PAC)组成联合调理剂,对堆存污泥进行脱水以及对其中重金属进行稳定化效果研究,并通过电镜-能谱探究加入调理剂后污泥的微观结构及物质构成。结果表明:添加固体废物材料的联合调理剂对污泥脱水及重金属稳定化效果显著,其中添加PG的组合最优。当CaO、PAC、PG添加量(干基比)分别为20%、25%、23%时,毛细吸水时间为42.1 s,泥饼含水率为49.00%;PG中丰富的孔隙结构及磷酸盐物质对重金属有很好的吸附和沉淀作用;微观结构分析显示,经过调理后CaSO4或Al2(SO4)3构建了污泥的骨架结构。

Abstract:The stocked sludge has the characteristics of high moisture content and potential heavy metal pollution, which may pose potential ecological risks to the landfill site and the surrounding environment. Three solid waste materials, straw powder (SP), fly ash (FA) and phosphogypsum (PG), combined with two common dehydrators, quick lime (CaO) and polyaluminium chloride (PAC), were used to dehydrate the stocked sludge and study the stabilization effect of heavy metals. In addition, the microstructure and composition of the dehydrated sludge cake were studied by SEM-EDS. The results showed that the combined conditioner with solid waste materials had significant effects on sludge dewatering and heavy metal stabilization, and the group with PG was the best. When the addition of CaO, PAC and PG (dry basis ratio) were 20%, 25% and 23% respectively, the capillary water absorption time was 42.1 s and the moisture content of mud cake was 49.00%. The rich pore structure and phosphate impurities in PG had good adsorption and precipitation effects on heavy metals. The microstructure analysis showed that CaSO4 or Al2(SO4)3 formed the skeleton structure of treated sludge.

-

Key words:

- stocked sludge /

- solid waste materials /

- deep dewatering /

- heavy metals stabilization /

- microstructure

-

表 1 堆存污泥中重金属浓度

Table 1. Heavy metal parameters of stocked sludge

mg/kg As Cd Cr Cu Ni Pb Zn 17.6 1.7 119.8 524.3 78.3 62.1 802.9 表 2 3种脱水泥饼浸出液中的重金属浓度

Table 2. Heavy metal content in three kinds of leaching solution of dehydrated sludge cake

mg/kg 重金属 CaO-PAC-SP CaO-PAC-FA CaO-PAC-PG As 2.4 1.2 0.2 Cd 0.3 0.1 0.3 Cr 6.7 0.8 0.3 Cu 13.5 5.1 4.3 Ni 0.9 0.6 0.1 Pb 3.3 0.3 1.2 Zn 18.1 4.5 3.2 -

[1] 住房和城乡建设部. 中国城市建设统计年鉴(2020年)[M]. 北京: 中国统计出版社, 2021. [2] 姚金玲, 王海燕, 于云江, 等.城市污水处理厂污泥重金属污染状况及特征[J]. 环境科学研究,2010,23(6):696-702. doi: 10.13198/j.res.2010.06.33.yaojl.007YAO J L, WANG H Y, YU Y J, et al. Pollution status and characteristics of heavy metals in sewage sludge from municipal wastewater treatment plants[J]. Research of Environmental Sciences,2010,23(6):696-702. doi: 10.13198/j.res.2010.06.33.yaojl.007 [3] 张辰, 谭学军, 王磊, 等.我国重点流域城市污泥重与溯源研究[J]. 给水排水,2019,45(2):39-44.ZHANG C, TANG X J, WANG L, et al. Heavy metals concentrations and their traceability in municipal sludge in major river basins of China[J]. Water & Wastewater Engineering,2019,45(2):39-44. [4] CHEN H, TENG Y, LU S, et al. Contamination features and health risk of soil heavy metals in China[J]. Science of the Total Environment,2015,512:143-153. [5] 张惠芳, 孙玲, 蔡申健, 等.城市污泥中重金属的去除及稳定化技术研究进展[J]. 环境工程,2014,32(12):82-86. doi: 10.13205/j.hjgc.201412019ZHANG H F, SUN L, CAI S J, et al. Research progress on immobilization and removal of heavy metals from municipal sludge[J]. Environmental Engineering,2014,32(12):82-86. doi: 10.13205/j.hjgc.201412019 [6] 朱英, 赵由才, 李鸿江, 等.污泥填埋稳定化过程中的物理, 化学性状变化[J]. 生态环境学报,2009,18(4):1207-1212. doi: 10.3969/j.issn.1674-5906.2009.04.001ZHU Y, ZHAO Y C, LI H J, et al. Transformation on the sludge physical and chemical properties in the landfill stability process[J]. Ecological and Environmental Sciences,2009,18(4):1207-1212. doi: 10.3969/j.issn.1674-5906.2009.04.001 [7] 顾晋饴, 张俊, 王俊杰, 等.江苏省光伏电池行业污泥产排污特征[J]. 环境工程技术学报,2018,8(3):343-348. doi: 10.3969/j.issn.1674-991X.2018.03.045GU J Y, ZHANG J, WANG J J, et al. Characteristics of sludge generation and discharge from photovoltaic cell industry in Jiangsu Province[J]. Journal of Environmental Engineering Technology,2018,8(3):343-348. doi: 10.3969/j.issn.1674-991X.2018.03.045 [8] 陈静涵, 何岩, 乔赵超, 等.不同调理方法强化污水厂污泥脱水性能的对比[J]. 环境工程,2019,37(2):84-89. doi: 10.13205/j.hjgc.201902015CHEN J H, HE Y, QIAO Z C, et al. Comparison of enhancement of sewage sludge dewaterability in wastewater treatment plants by different conditioning methods[J]. Environmental Engineering,2019,37(2):84-89. doi: 10.13205/j.hjgc.201902015 [9] HAROUN M, IDRIS A, OMAR S. Analysis of heavy metals during composting of the tannery sludge using physicochemical and spectroscopic techniques[J]. Journal of Hazardous Materials,2009,165(1/2/3):111-119. [10] 石万里, 张大鹏, 赵泽华, 等.化学法调理生化污泥脱水效果研究[J]. 环境工程技术学报,2020,10(2):273-279. doi: 10.12153/j.issn.1674-991X.20190114SHI W L, ZHANG D P, ZHAO Z H, et al. Study on the effect of chemical conditioning method on the dewatering effect of biochemical sludge[J]. Journal of Environmental Engineering Technology,2020,10(2):273-279. doi: 10.12153/j.issn.1674-991X.20190114 [11] SHI Q, LU Y, GUO W, et al. Application of a cellulose filter aid in municipal sewage sludge dewatering and drying: jar, pilot, and factory scale[J]. Water Environment Research,2020,92(4):495-503. doi: 10.1002/wer.1254 [12] 沈蔚然, 周俊, 李想, 等.不同调理剂对厌氧石化污泥脱水性能的影响研究[J]. 环境工程,2017,35(9):117-121. doi: 10.13205/j.hjgc.201709023SHEN W R, ZHOU J, LI X, et al. Effect of different conditioning agents on the petrochemical anaerobic sludge's dewatering performance[J]. Environmental Engineering,2017,35(9):117-121. doi: 10.13205/j.hjgc.201709023 [13] AMIR S, HAFIDI M, MERLINA G, et al. Sequential extraction of heavy metals during composting of sewage sludge[J]. Chemosphere,2005,59(6):801-810. doi: 10.1016/j.chemosphere.2004.11.016 [14] 毛芸. 污泥重金属稳定化初步研究[D]. 广州: 中山大学, 2005. [15] ZHAO Y. Enhancement of alum sludge dewatering capacity by using gypsum as skeleton builder[J]. Colloids and Surfaces A:Physicochemical and Engineering Aspects,2002,211(2/3):205-212. [16] LIN Y F, JING S R, LEE D Y. Recycling of wood chips and wheat dregs for sludge processing[J]. Bioresource Technology,2001,76(2):161-163. doi: 10.1016/S0960-8524(00)00098-5 [17] 刘强, 陈晓欢, 傅金祥, 等.粉煤灰与生石灰复合调理剂对市政污泥深度脱水性能的影响[J]. 环境工程学报,2015,9(7):3468-3472. doi: 10.12030/j.cjee.20150763LIU Q, CHEN X H, FU J X, et al. Effect of fly ash combined quicklime composite conditioners on dewatering of sewage sludge[J]. Chinese Journal of Environmental Engineering,2015,9(7):3468-3472. doi: 10.12030/j.cjee.20150763 [18] WONG J, SELVAM A. Speciation of heavy metals during co-composting of sewage sludge with lime[J]. Chemosphere,2006,63(6):980-986. doi: 10.1016/j.chemosphere.2005.08.045 [19] 曹亚丽, 钱光人.利用城市垃圾焚烧飞灰稳定固化含重金属工业污泥的试验研究[J]. 环境工程,2008,26(增刊 1):235-240.CAO Y L, QIAN G R. Research on the utilization of MSWI fly ash for stabilization and solidification of heavy metals-bearing industrial sludge[J]. Environmental Engineering,2008,26(Suppl 1):235-240. [20] 徐聪珑, 尹秀玲, 张文卿, 等.不同钝化剂对城市地下固体废弃物重金属的钝化作用[J]. 科学技术与工程,2016,16(19):305-308. doi: 10.3969/j.issn.1671-1815.2016.19.053XU C L, YIN X L, ZHANG W Q, et al. Passivation effect of stabilitying materials on heavy metals in municipal solid waste[J]. Science Technology and Engineering,2016,16(19):305-308. doi: 10.3969/j.issn.1671-1815.2016.19.053 [21] 王建新, 李晶, 赵仕宝, 等.中国粉煤灰的资源化利用研究进展与前景[J]. 硅酸盐通报,2018,37(12):3833-3841. doi: 10.16552/j.cnki.issn1001-1625.2018.12.020WANG J X, LI J, ZHAO S B, et al. Research progress and prospect of resource utilization of fly ash in China[J]. Bulletin of the Chinese Ceramic Society,2018,37(12):3833-3841. doi: 10.16552/j.cnki.issn1001-1625.2018.12.020 [22] 吴琼慧, 刘志学, 陈业阳, 等.长江经济带“三磷”行业环境管理现状及对策建议[J]. 环境科学研究,2020,33(5):1233-1240. doi: 10.13198/j.issn.1001-6929.2020.03.28WU Q H, LIU Z X, CHEN Y Y, et al. Status and countermeasures of environmental management of the "Three Phosphorus" industry in the Yangtze River Economic Belt[J]. Research of Environmental Sciences,2020,33(5):1233-1240. doi: 10.13198/j.issn.1001-6929.2020.03.28 [23] 王永振, 高辉, 赵江, 等.秸秆资源综合利用技术概述[J]. 环境工程,2014,32(增刊 1):730-733. doi: 10.13205/j.hjgc.2014.s1.243WANG Y Z, GAO H, ZHAO J, et al. Summary of the comprehensive utilization of straw resources[J]. Environmental Engineering,2014,32(Suppl 1):730-733. doi: 10.13205/j.hjgc.2014.s1.243 [24] 杨耿, 秦延文, 马迎群, 等.沱江流域磷石膏的磷形态组成及潜在释放特征[J]. 环境工程技术学报,2018,8(6):610-616. doi: 10.3969/j.issn.1674-991X.2018.06.081YANG G, QIN Y W, MA Y Q, et al. Phosphorus forms and potential release characteristics of phosphogypsum in Tuojiang River Basin[J]. Journal of Environmental Engineering Technology,2018,8(6):610-616. doi: 10.3969/j.issn.1674-991X.2018.06.081 [25] WANG H F, WANG H J, HU H, et al. Applying rheological analysis to understand the mechanism of polyacrylamide (PAM) conditioning for sewage sludge dewatering[J]. RSC advances,2017,7(48):30274-30282. doi: 10.1039/C7RA05202B [26] KIM H C, HONG J H, LEE S. Fouling of microfiltration membranes by natural organic matter after coagulation treatment: a comparison of different initial mixing conditions[J]. Journal of Membrane Science,2006,283(1/2):266-272. [27] 徐露露, 马友华, 马铁铮, 等.钝化剂对土壤重金属污染修复研究进展[J]. 农业资源与环境学报,2013,30(6):25-29. doi: 10.3969/j.issn.1005-4944.2013.06.005XU L L, MA Y H, MA T Z, et al. Passivating agents on remediation of heavy metal pollution in soils[J]. Journal of Agricultural Resources and Environment,2013,30(6):25-29. doi: 10.3969/j.issn.1005-4944.2013.06.005 [28] 钟倩云, 曾敏, 廖柏寒, 等.2种固化剂对重金属和砷复合污染底泥的稳定化处理效果[J]. 水土保持学报,2012,26(6):190-193. doi: 10.13870/j.cnki.stbcxb.2012.06.012ZHONG Q Y, ZENG M, LIAO B H, et al. Effect of two immobilization materials on stabilization treatment for heavy metal and arsenic compound polluted sediment[J]. Journal of Soil and Water Conservation,2012,26(6):190-193. ⊗ doi: 10.13870/j.cnki.stbcxb.2012.06.012 -

下载:

下载: