Effect of sludge-rice husk co-incineration on the recovery efficiency of sludge phosphorus resources

-

摘要:

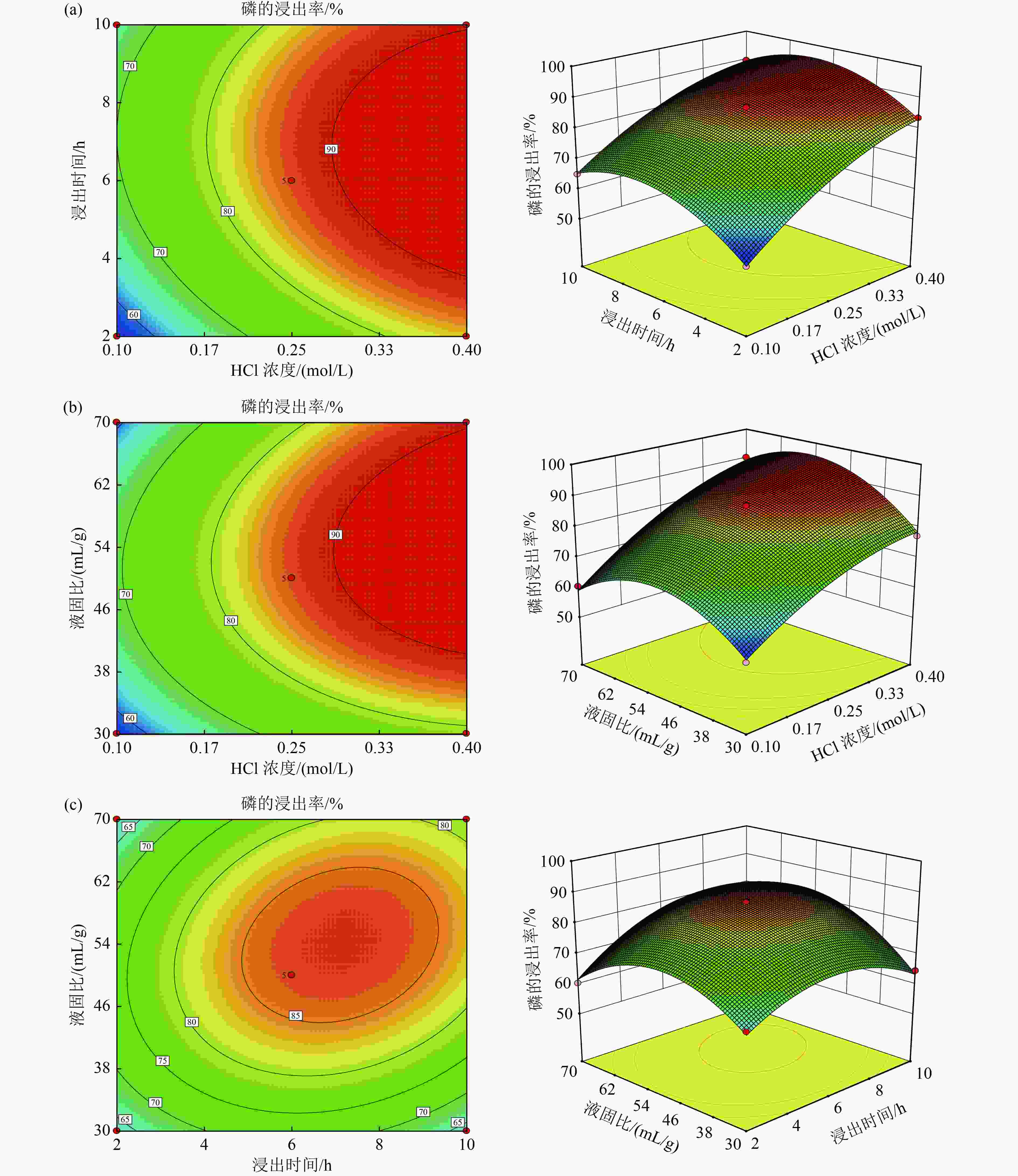

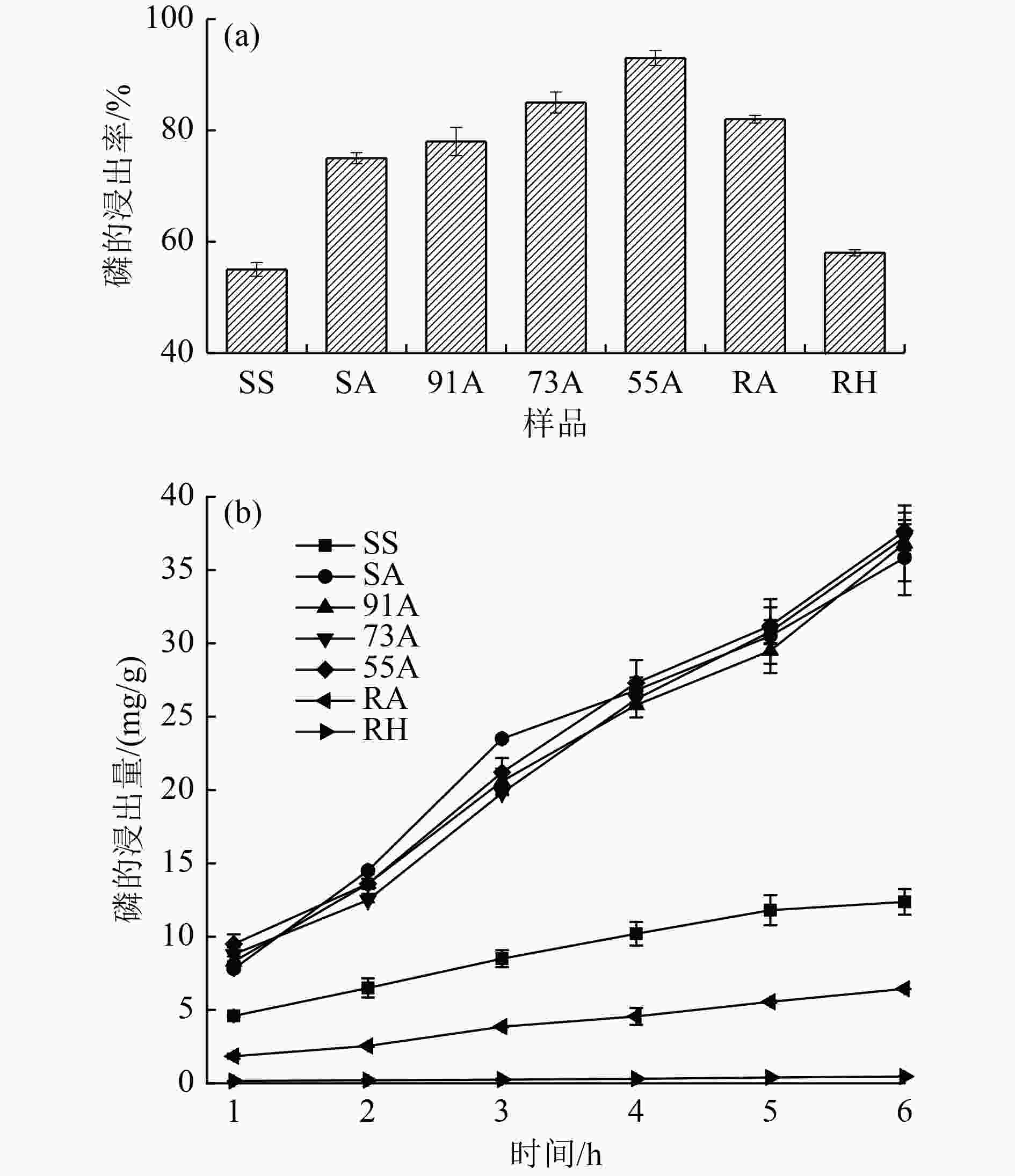

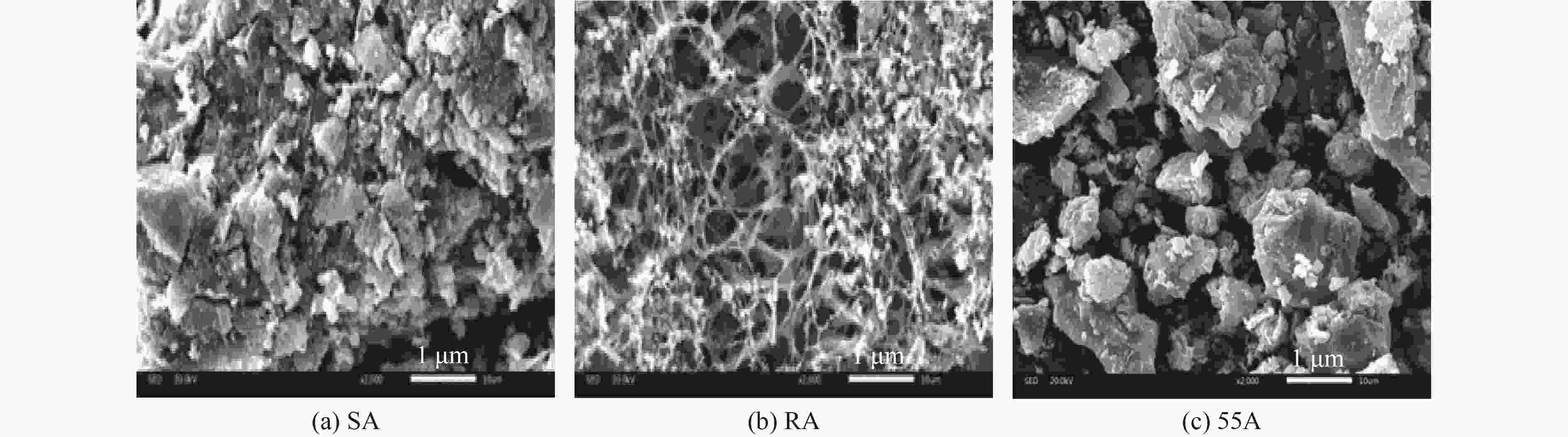

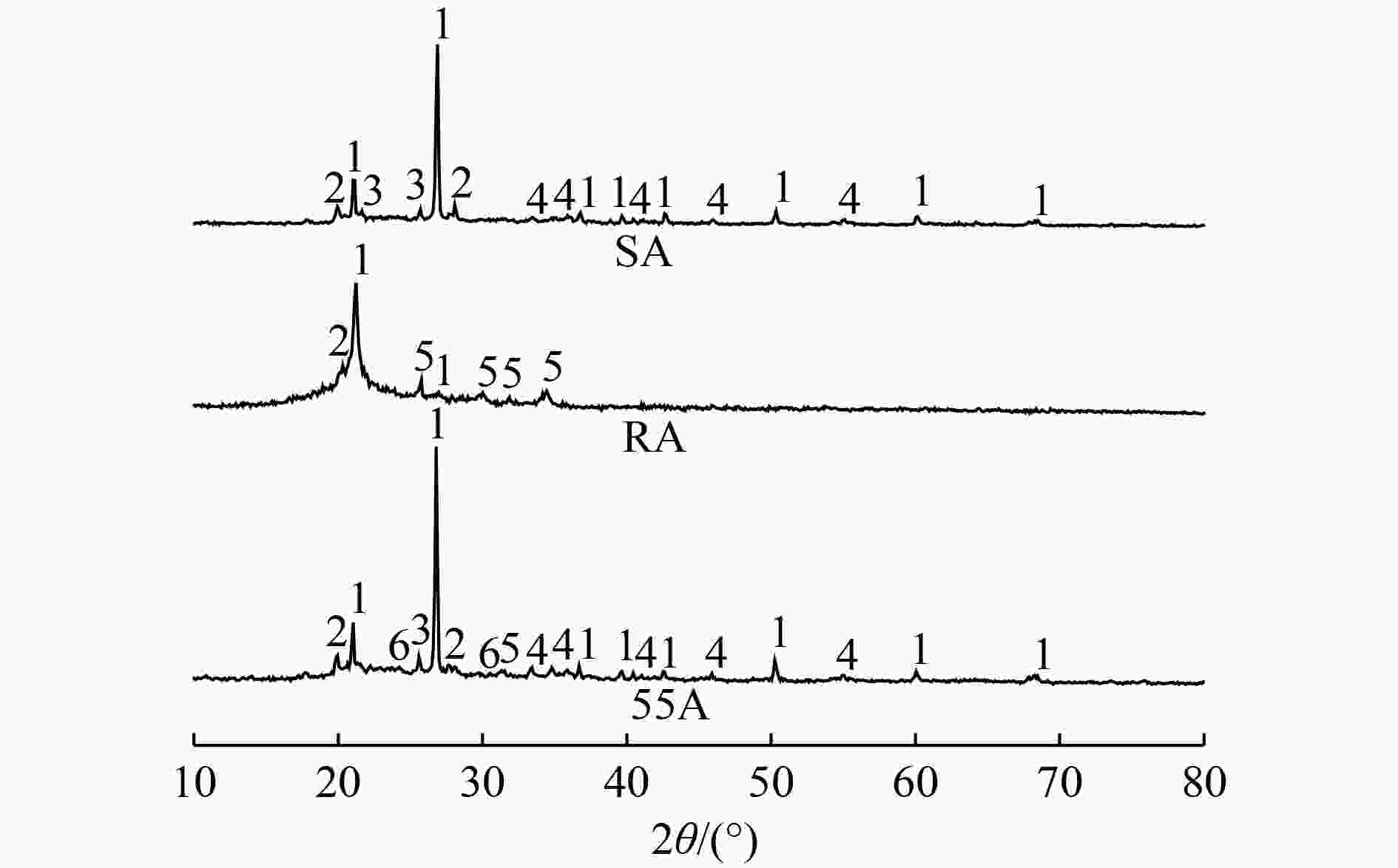

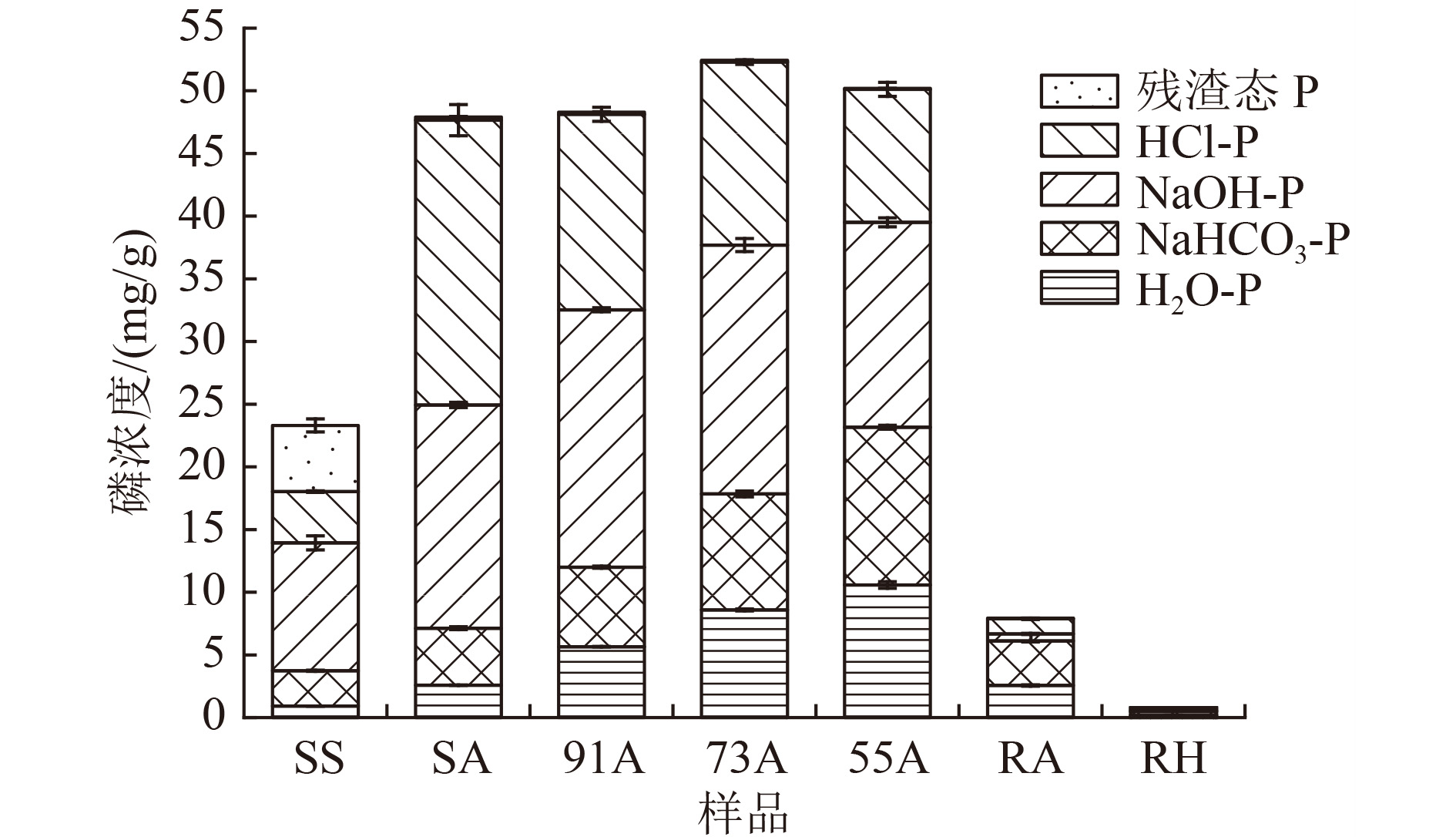

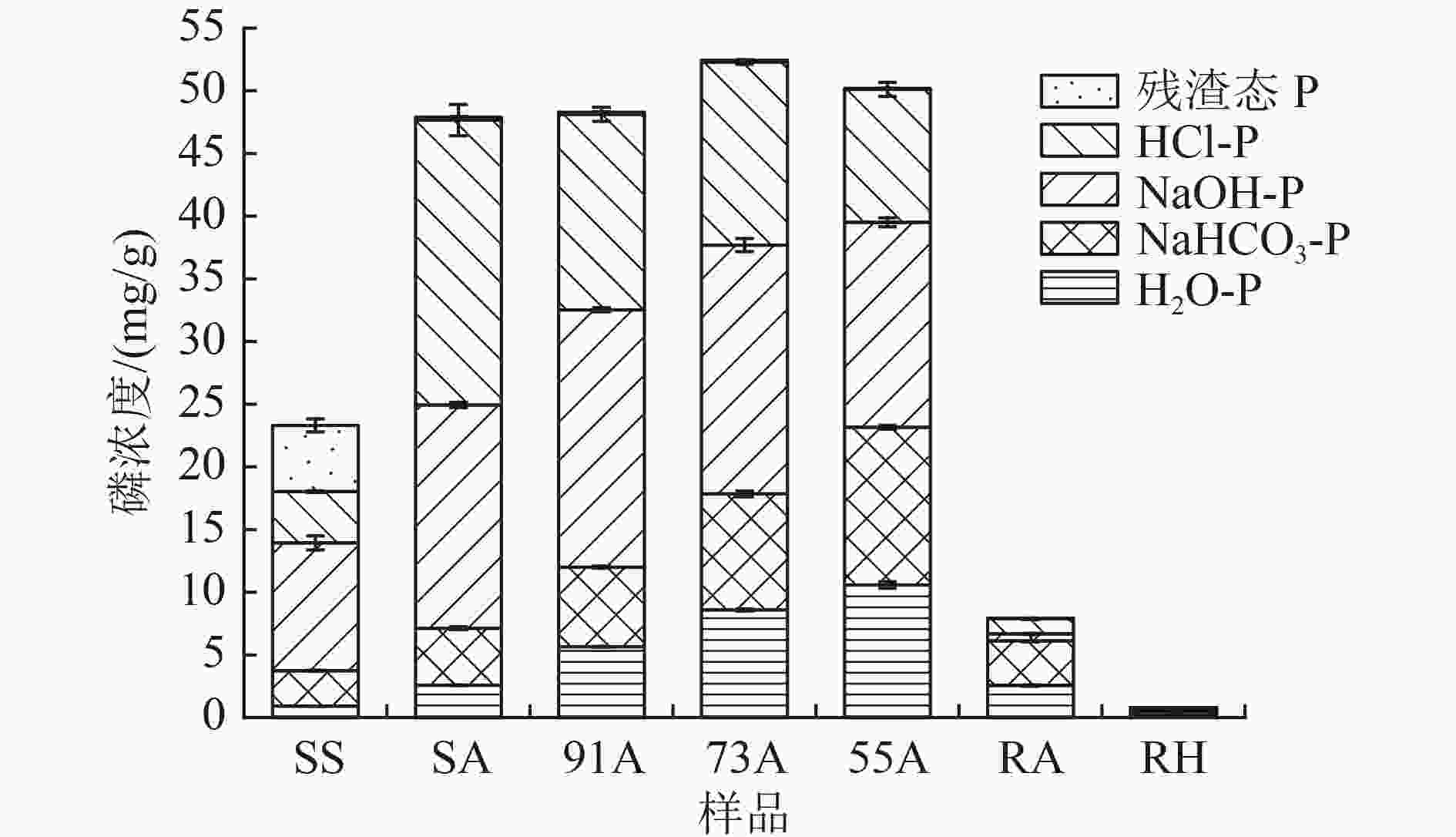

污水处理厂污泥中含有丰富的营养元素磷,回收其中的磷在一定程度上能缓解磷资源的衰竭。利用焚烧法处理污泥,以稻壳作为添加物,采用Hedley逐级提取法和酸浸出法考察污泥-稻壳焚烧灰中磷的形态和浸出效果的变化,并探讨稻壳添加量对焚烧灰中磷形态的影响。结果表明:当稻壳添加量为总质量的50%时,磷的生物可利用性最高;响应曲面法优化结果表明,最佳试验条件是HCl浓度、浸出时间和液固比分别为0.33 mol/L,6.4 h和50 mL/g,该条件下,磷的浸出率达93%,与污泥焚烧灰相比提高了20%;比较污泥灰、稻壳灰及污泥-稻壳混烧灰的理化性质可知,污泥-稻壳协同焚烧并未改变污泥灰和稻壳灰的主要组分,但出现了新的物相,形貌也发生了一定变化。污泥-稻壳协同焚烧能提高焚烧灰中磷的浸出率,从而有利于从污泥中回收磷资源。

Abstract:The sludge of sewage treatment plants is rich in phosphorus and recycling phosphorus from sludge can alleviate phosphorus depletion to a certain extent. Sludge was treated by incineration, with rice husk as an additive, and the variation of phosphorus fraction and extraction efficiency in sludge-rice husk incineration ash were investigated by using Hedley's stepwise extraction method and acid extraction method. The effect of rice husk dose on phosphorus fraction in incineration ash was explored. The results showed that the phosphorus bioavailability was the best when the dose of rice husk was 50% of the total mass. Based on the optimization by response surface method, the optimal condition was found that HCl concentration, extraction time, and the ratio of liquid and solid were 0.33 mol/L, 6.4 h, and 50 mL/g, respectively. The phosphorus extraction efficiency at the optimal experimental condition was as high as 93%, which was 20% higher than that of sludge incineration ash. Through comparing the physical and chemical properties of sludge ash, rice husk ash and ash of co-incineration, it was found that the co-incineration of sludge and rice husk did not change the main components of sludge ash and rice husk ash, but the new phase was generated and the morphology changed. The results illustrated that the co-incineration of sludge and rice husk could improve the phosphorus extraction efficiency of incineration ashes, which was beneficial to the recovery of phosphorus resources from sludge.

-

Key words:

- sludge /

- rice husk /

- incineration ash /

- phosphorus /

- acid extraction /

- co-incineration

-

表 1 污泥与稻壳的基本性质

Table 1. Basic properties of sludge and rice husk

样品 含水率/% pH 污泥 56.68±0.50 6.84±0.05 稻壳 8.25±0.40 7.45±0.03 表 2 污泥和稻壳的工业分析和元素分析

Table 2. Proximate analysis and elemental analysis of sludge and rice husk

% 样品 灰分 挥发分 固定碳 C H N O 污泥 47.35 40.25 12.40 28.41 4.62 4.75 14.84 稻壳 11.25 78.56 10.19 40.61 5.83 0.80 41.57 表 3 污泥和稻壳的化学组成

Table 3. Chemical composition of sludge and rice husk

% 样品 SiO2 MgO Fe2O3 Na2O CaO Al2O3 K2O SO3 P2O3 LOI1) 污泥 17.0 0.94 3.79 3.79 2.43 8.59 1.15 0.34 5.34 56.98 稻壳 8.40 0.11 0.08 0.03 0.16 2.32 0.60 0.22 0.22 87.75 1) LOI表示1 200 ℃时的质量损失率。 表 4 不同焚烧灰的产率和总磷浓度

Table 4. Yield and total phosphorus content of different incineration ashes

试验组 焚烧灰产率/% 总磷浓度/(mg/g) SA 48.4±1.05 47.8±1.25 91A 44.7±0.78 47.2±0.85 73A 37.2±0.56 43.8±0.56 55A 29.7±0.49 40.5±0.35 RA 11.2±0.25 7.85±0.78 表 5 BBD试验设计因素和水平

Table 5. Design factors and levels in BBD experiments

因素 编号 水平范围 低 高 −1 1 HCl浓度/(mol/L) A 0.1 0.4 浸出时间/h B 2 10 液固比/(mL/g) C 30 70 表 6 BBD试验设计和磷去除效果

Table 6. BBD experimental design and phosphorus removal efficiency

序号 编号 Pe/% A B C 1 0.10 10 50 65.1 2 0.10 6 30 55.8 3 0.25 6 50 86.5 4 0.25 2 70 60.4 5 0.40 10 50 89.7 6 0.25 6 50 87.1 7 0.40 2 50 83.6 8 0.40 6 70 90.2 9 0.25 10 70 77.0 10 0.25 6 50 86.4 11 0.25 6 50 86.9 12 0.25 6 50 87.2 13 0.40 6 30 77.2 14 0.25 2 30 64.1 15 0.25 10 30 64.6 16 0.10 6 70 60.5 17 0.10 2 50 55.1 表 7 SA、RA、55A的化学组成

Table 7. Chemical composition of SA, RA and 55A

% 样品 SiO2 MgO Fe2O3 Na2O CaO Al2O3 K2O SO3 P2O3 SA 42.5 1.89 7.98 5.25 4.12 17.28 2.52 1.02 9.83 RA 82.5 0.95 0.85 0.28 0.95 5.68 4.95 0.85 1.85 55A 55.8 1.75 7.66 3.56 2.59 14.9 3.61 0.92 7.65 -

[1] STEEN I. Phosphorus availability in the 21st century: management of a non-renewable resource[J]. Phosphorus and Potassium,1998,217:25-31. [2] 魏金山, 刘雪瑜, 宋永会, 等.氧化镁与白云石石灰对不同来源废水中磷的回收效果[J]. 环境科学研究,2015,28(11):1734-1740. doi: 10.13198/j.issn.1001-6929.2015.11.11WEI J S, LIU X Y, SONG Y H, et al. Phosphorus recovery from wastewaters of different sources with magnesium and dolomite lime[J]. Research of Environmental Sciences,2015,28(11):1734-1740. doi: 10.13198/j.issn.1001-6929.2015.11.11 [3] ZHU W, XU Z R, LI L, et al. The behavior of phosphorus in sub- and super-critical water gasification of sewage sludge[J]. Chemical Engineering Journal,2011,171(1):190-196. doi: 10.1016/j.cej.2011.03.090 [4] SOMMERS L E. Chemical composition of sewage sludges and analysis of their potential use as fertilizers[J]. Journal of Environmental Quality,1977,6(2):225-232. [5] XU Y F, HU H, LIU J Y, et al. pH dependent phosphorus release from waste activated sludge: contributions of phosphorus speciation[J]. Chemical Engineering Journal,2015,267:260-265. doi: 10.1016/j.cej.2015.01.037 [6] 冯春, 杨光, 杜俊, 等.污水污泥堆肥重金属总量及形态变化[J]. 环境科学研究,2008,21(1):97-102. doi: 10.13198/j.res.2008.01.103.fengch.022FENG C, YANG G, DU J, et al. Study on the changes of total contents and the status of heavy metals for sewage sludge composting[J]. Research of Environmental Sciences,2008,21(1):97-102. doi: 10.13198/j.res.2008.01.103.fengch.022 [7] 刘敬勇, 孙水裕.城市污泥焚烧过程中重金属形态与分布的热力学平衡分析[J]. 中国有色金属学报,2010,20(8):1645-1655. doi: 10.19476/j.ysxb.1004.0609.2010.08.031LIU J Y, SUN S Y. Thermodynamic equilibrium analysis of heavy metals speciation transformation and distribution during sewage sludge incineration[J]. The Chinese Journal of Nonferrous Metals,2010,20(8):1645-1655. doi: 10.19476/j.ysxb.1004.0609.2010.08.031 [8] WANG Q M, LI J S, TANG P, et al. Sustainable reclamation of phosphorus from incinerated sewage sludge ash as value-added struvite by chemical extraction, purification and crystallization[J]. Journal of Cleaner Production,2018,181:717-725. doi: 10.1016/j.jclepro.2018.01.254 [9] 王腾. 污泥-稻壳混烧灰熔融特性及自固化机理研究[D]. 武汉: 武汉大学, 2017. [10] WZOREK Z, JODKO M, GORAZDA K, et al. Extraction of phosphorus compounds from ashes from thermal processing of sewage sludge[J]. Journal of Loss Prevention in the Process Industries,2006,19(1):39-50. doi: 10.1016/j.jlp.2005.05.014 [11] HEDLEY M J, STEWART J W B, CHAUHAN B S. Changes in inorganic and organic soil phosphorus fractions induced by cultivation practices and by laboratory incubations[J]. Soil Science Society of America Journal,1982,46(5):970-976. doi: 10.2136/sssaj1982.03615995004600050017x [12] TURNER B L, LEYTEM A B. Phosphorus compounds in sequential extracts of animal manures: chemical speciation and a novel fractionation procedure[J]. Environmental Science & Technology,2004,38(22):6101-6108. [13] SMITH A M, SINGH S, ROSS A B. Fate of inorganic material during hydrothermal carbonisation of biomass: influence of feedstock on combustion behaviour of hydrochar[J]. Fuel,2016,169:135-145. doi: 10.1016/j.fuel.2015.12.006 [14] LI M, TANG Y Y, LU X Y, et al. Phosphorus speciation in sewage sludge and the sludge-derived biochar by a combination of experimental methods and theoretical simulation[J]. Water Research,2018,140:90-99. doi: 10.1016/j.watres.2018.04.039 [15] HUANG R X, TANG Y Z. Evolution of phosphorus complexation and mineralogy during (hydro) thermal treatments of activated and anaerobically digested sludge: insights from sequential extraction and P K-edge XANES[J]. Water Research,2016,100:439-447. doi: 10.1016/j.watres.2016.05.029 [16] FERREIRA S L C, BRUNS R E, FERREIRA H S, et al. Box-Behnken design: an alternative for the optimization of analytical methods[J]. Analytica Chimica Acta,2007,597(2):179-186. doi: 10.1016/j.aca.2007.07.011 [17] XIONG Q, WU X, LV H, et al. Influence of rice husk addition on phosphorus fractions and heavy metals risk of biochar derived from sewage sludge[J]. Chemosphere,2021,280:130566. doi: 10.1016/j.chemosphere.2021.130566 [18] 陈昊铭. 市政污泥焚烧过程磷形态转变及焚烧灰草酸浸出磷回收的研究[D]. 武汉: 华中科技大学, 2019. [19] LI L M, YU C J, BAI J S, et al. Heavy metal characterization of circulating fluidized bed derived biomass ash[J]. Journal of Hazardous Materials,2012,233/234:41-47. doi: 10.1016/j.jhazmat.2012.06.053 [20] JIN J W, LI Y N, ZHANG J Y, et al. Influence of pyrolysis temperature on properties and environmental safety of heavy metals in biochars derived from municipal sewage sludge[J]. Journal of Hazardous Materials,2016,320:417-426. doi: 10.1016/j.jhazmat.2016.08.050 [21] WANG T, XUE Y J, ZHOU M, et al. Effect of addition of rice husk on the fate and speciation of heavy metals in the bottom ash during dyeing sludge incineration[J]. Journal of Cleaner Production,2020,244:118851. ⊗ doi: 10.1016/j.jclepro.2019.118851 -

下载:

下载: