Study on natural water loss characteristics and mathematical model of CaO conditioned sludge

-

摘要:

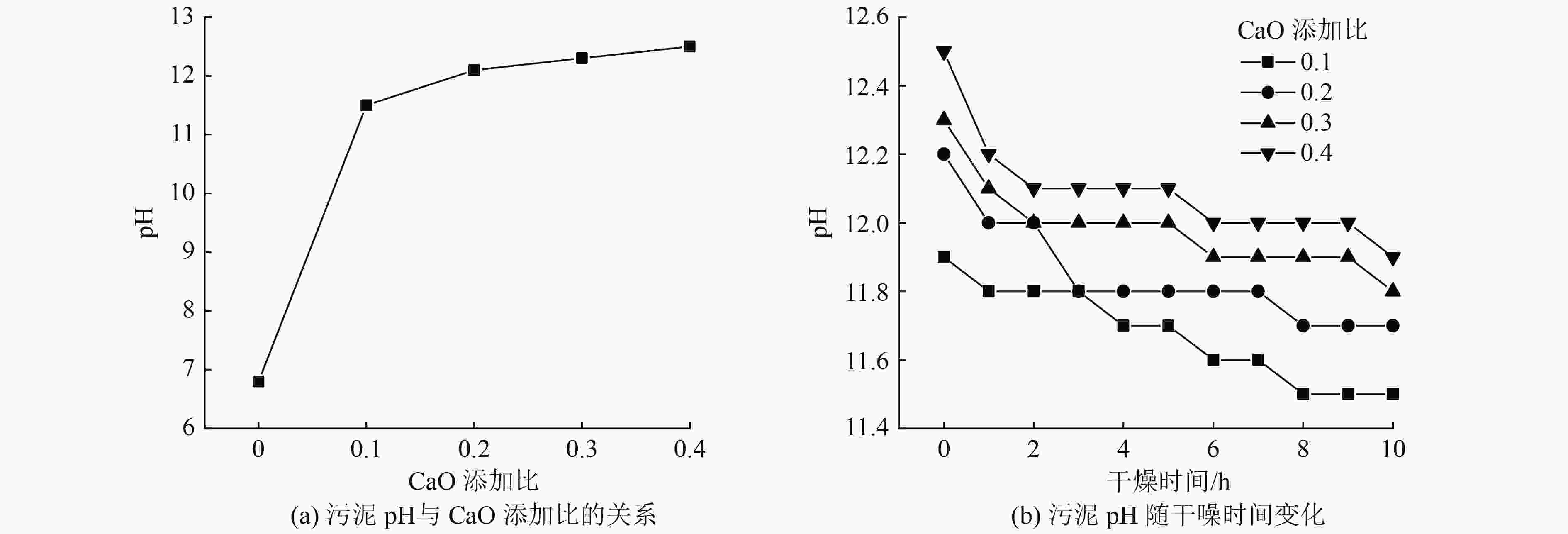

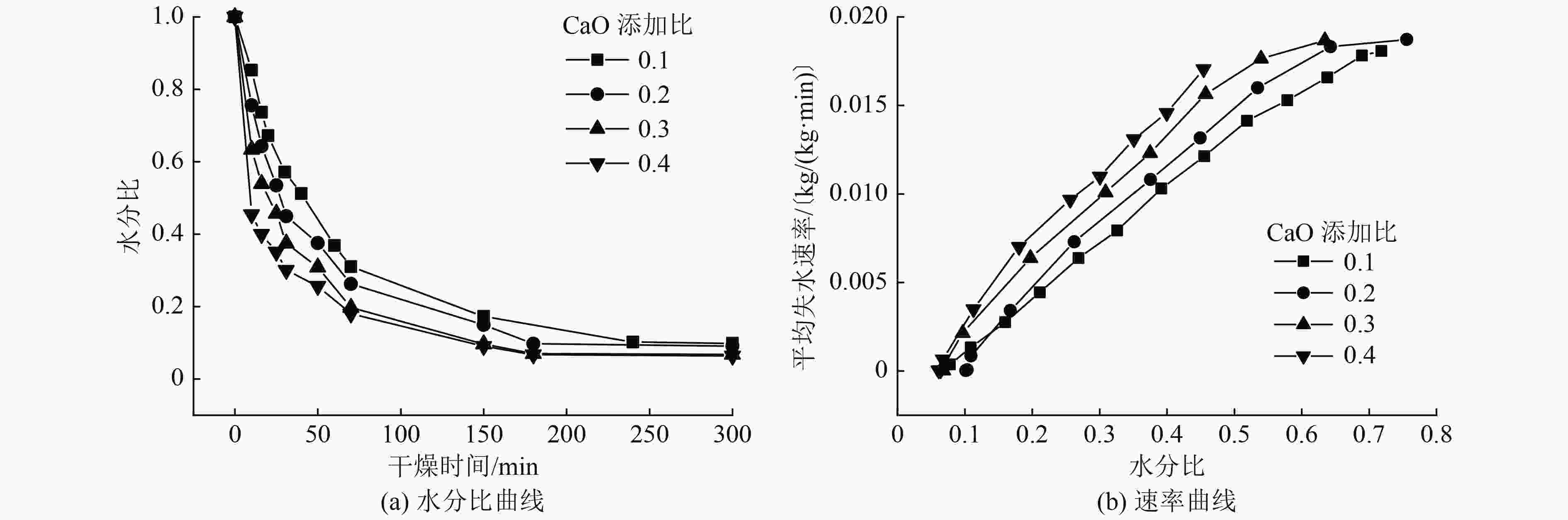

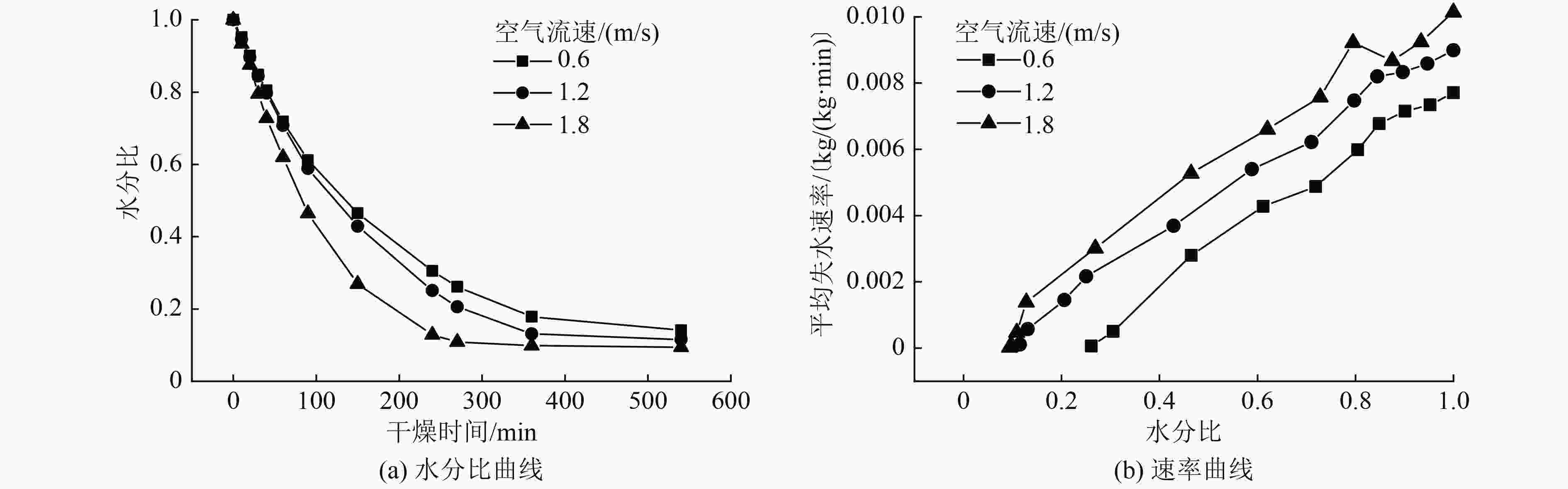

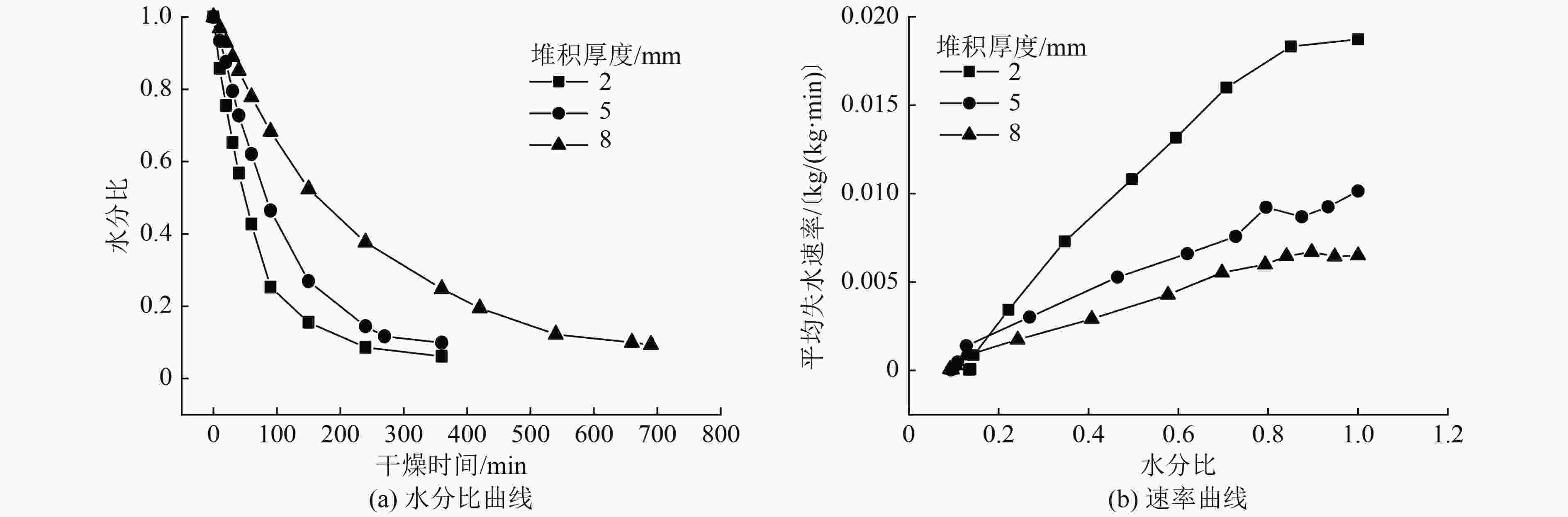

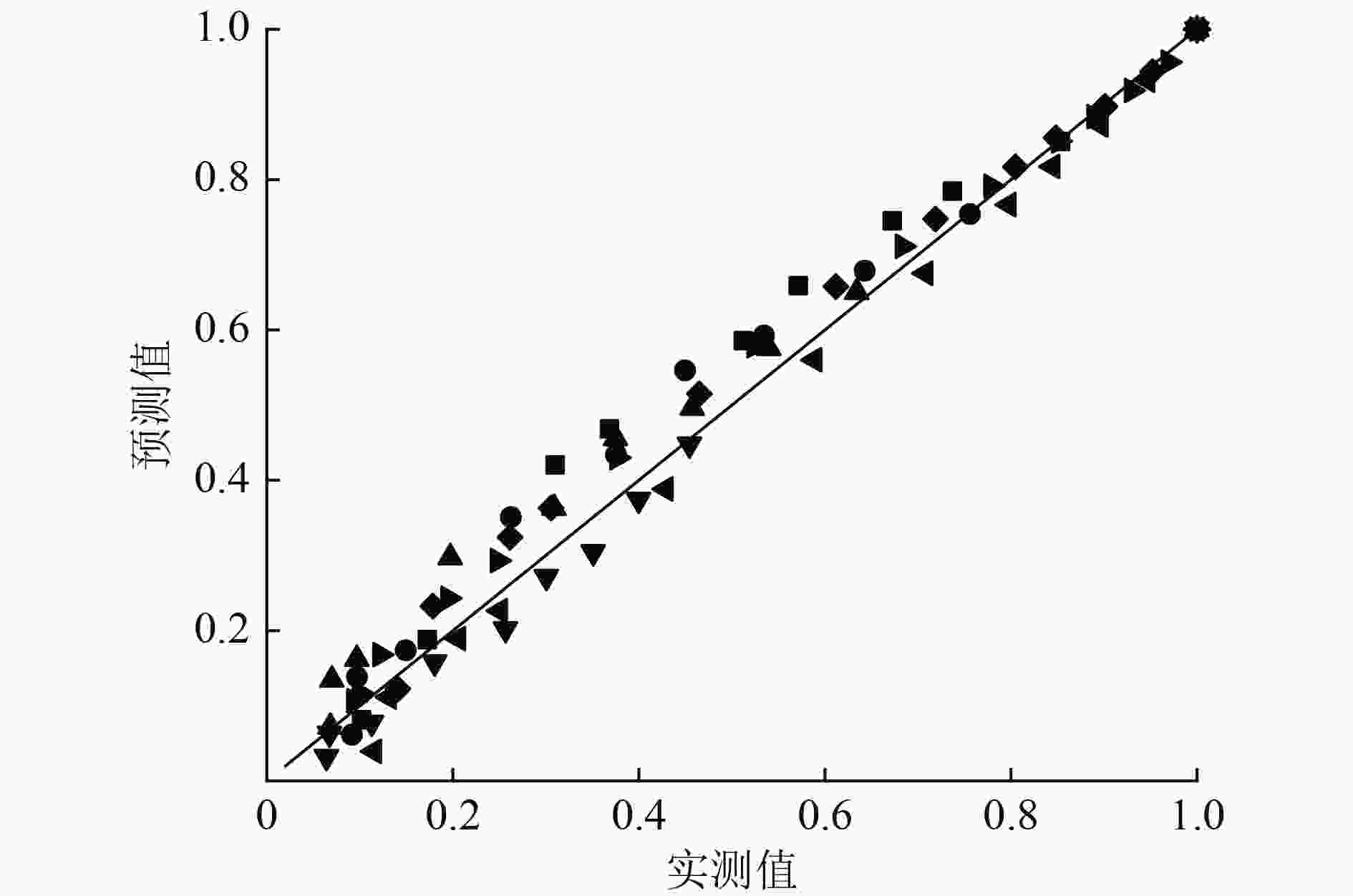

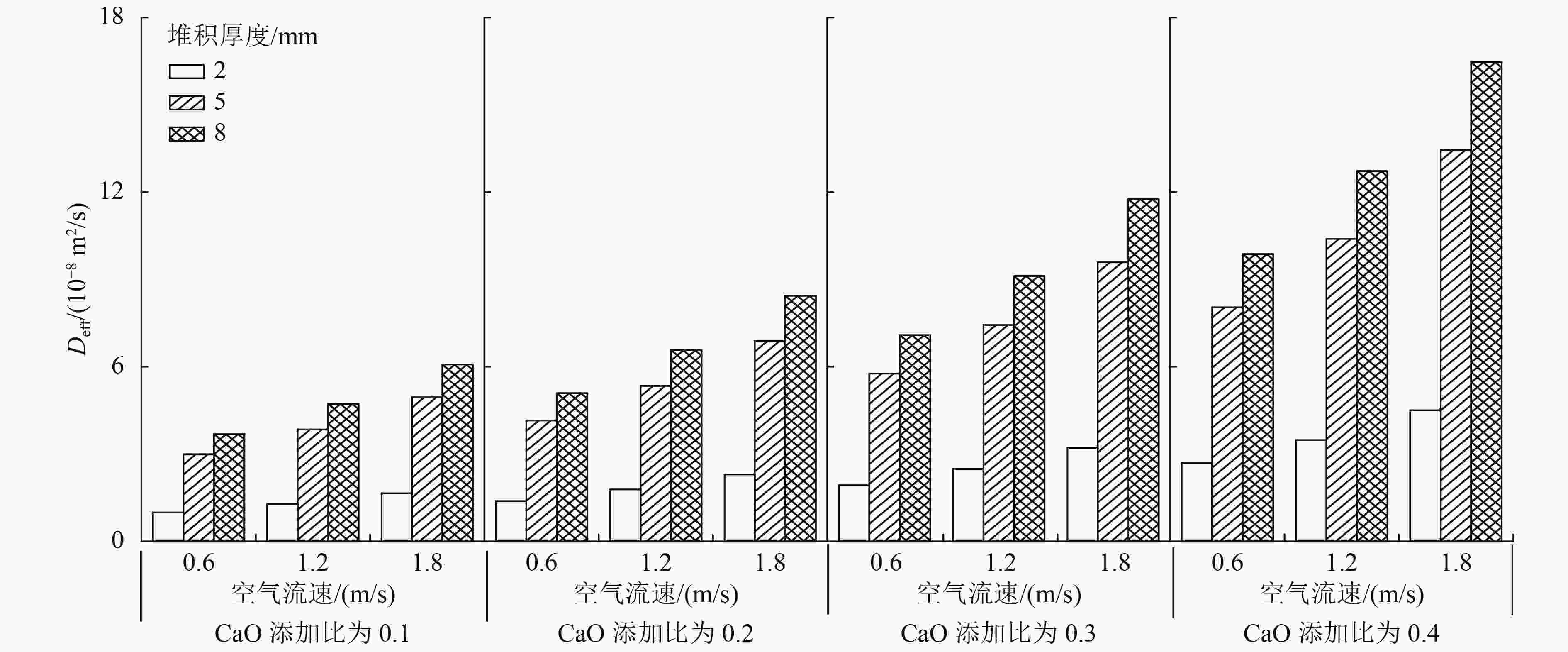

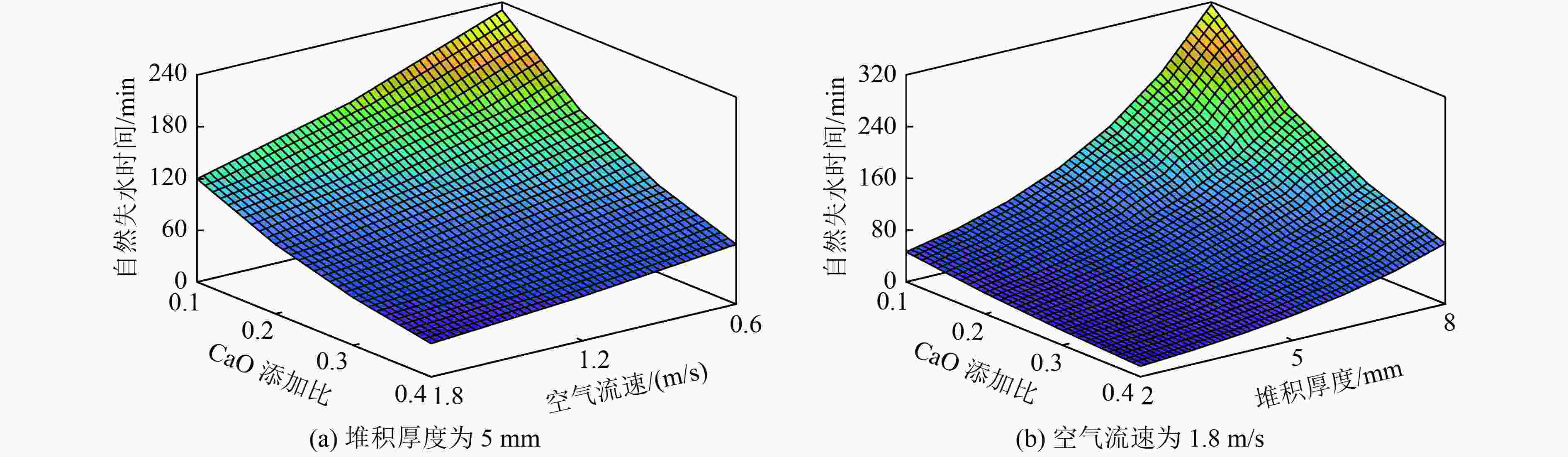

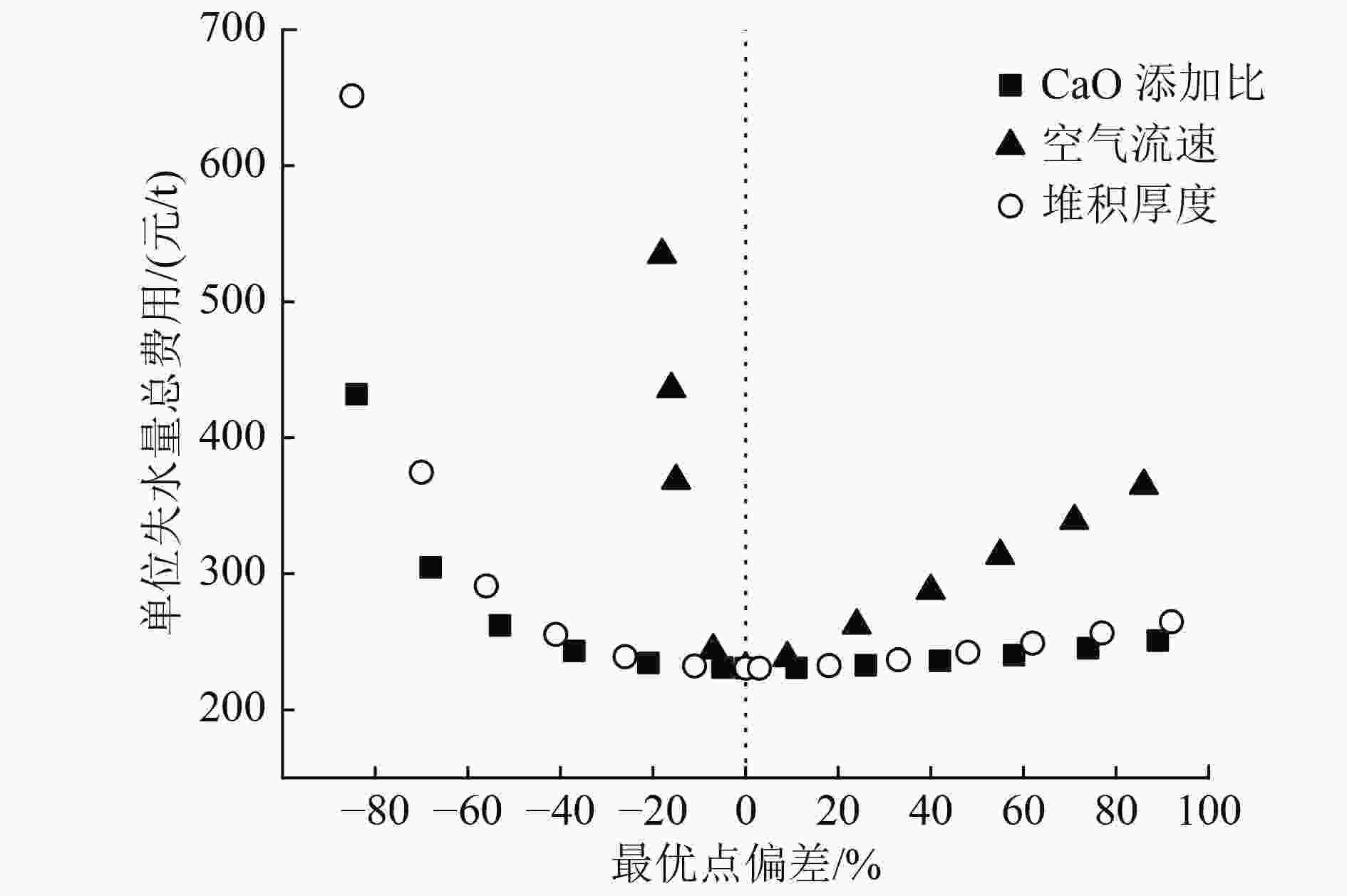

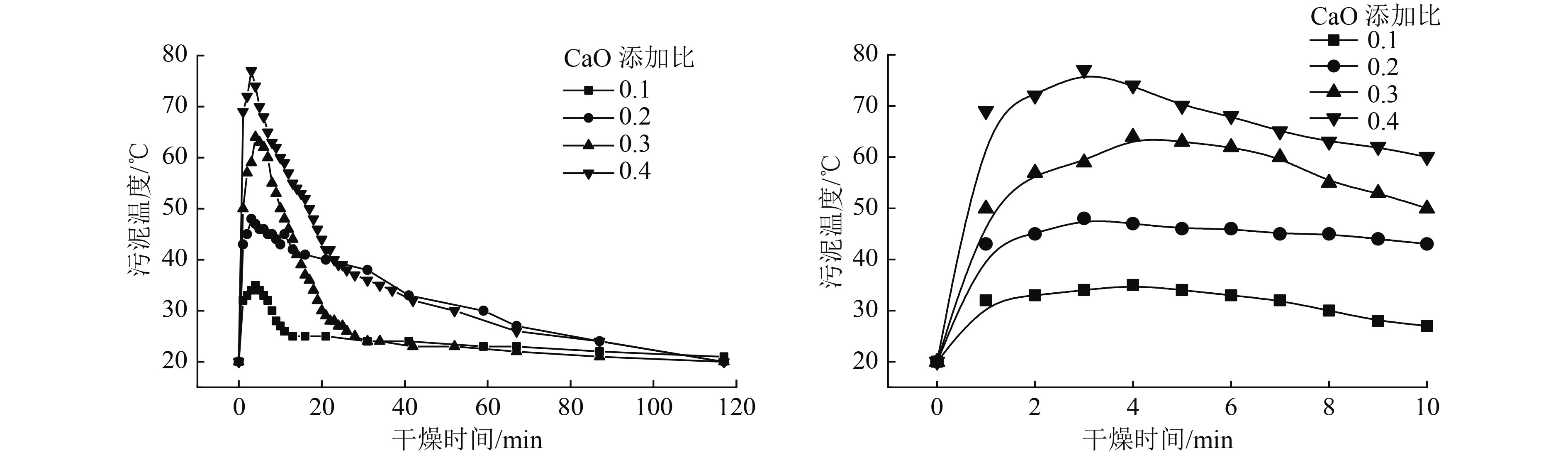

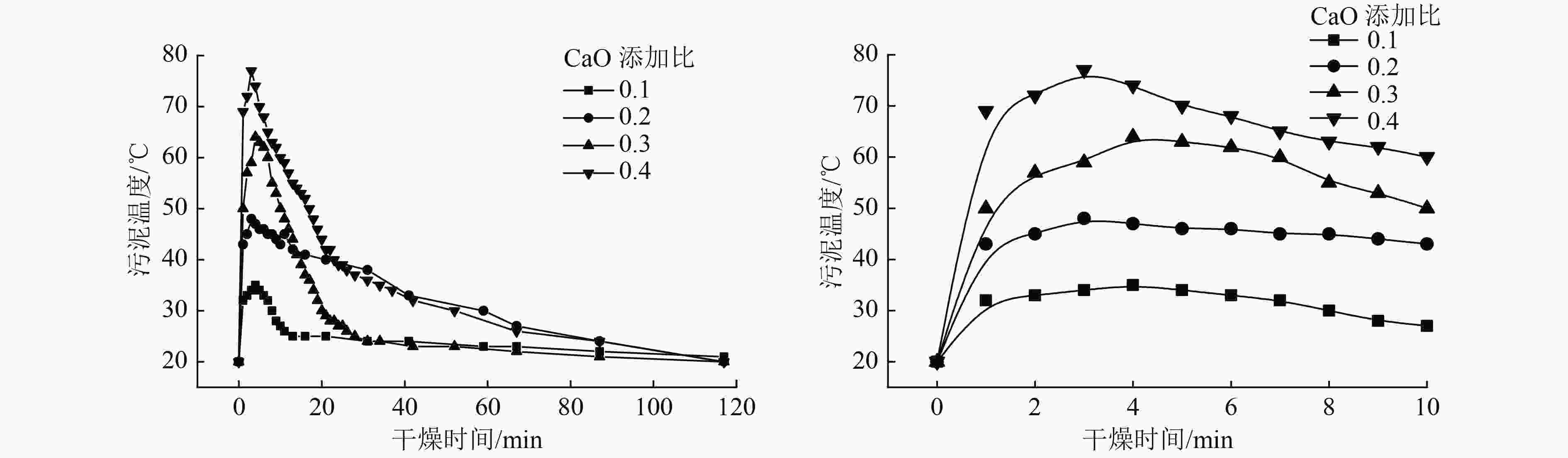

以城市污泥为对象,研究CaO添加比、空气流速及污泥堆积厚度对CaO调质污泥自然失水特性的影响。结果表明:污泥失水速率与空气流速、CaO添加比成正比,与堆积厚度成反比。基于Page模型建立的通用模型拟合值与实测值吻合较好,均方根误差为6.34%,能较好地模拟CaO调质污泥自然失水过程。根据Page模型计算出的污泥有效水分扩散系数为9.96×10−9~1.65×10−7,自然失水时间与CaO添加比、空气流速呈正相关,与污泥堆积厚度呈负相关。以单位失水量总费用为评价指标,采用MATLAB软件中Fmincon函数计算出单位失水量总费用最低时的最优干燥参数组合:CaO添加比为0.02,空气流速为0.6 m/s,污泥堆积厚度为7 mm。

Abstract:The effects of CaO addition ratio, airflow rate and bulking thickness on the natural water loss characteristics of municipal sludge treated by CaO were studied. The results showed that sludge water loss rate was proportional to airflow rate and CaO addition ratio, but inversely proportional to bulking thickness. The experimental data were well fitted by the general model based on the Page model with the root mean square error of 6.34%, which could better simulate the natural dewatering process of CaO-treated sludge. The effective water diffusion coefficient of the sludge calculated using the Page model was 9.96×10−9-1.65×10−7. The natural water loss time was positively correlated with the CaO addition ratio and airflow rate, and negatively correlated with the bulking thickness. Using the total cost per unit water loss as the evaluation index, the Fmincon function in MATLAB software was applied to calculate the optimal drying parameters under the condition of the lowest total cost per unit water loss. The optimal combination of drying parameters was: CAO addition ratio 0.02, airflow rate 0.6 m/s, sludge accumulation thickness 7 mm.

-

Key words:

- sludge /

- CaO conditioning /

- natural water loss /

- mathematical model /

- parameter optimization

-

表 1 常用薄层干燥模型及拟合结果

Table 1. Common thin-layer drying models and fitting results

表 2 Page模型统计分析结果

Table 2. Statistical analysis results of Page model

模型方程 CaO添加比 空气流速/(m/s) 堆积厚度/mm R2 χ2 模型参数 k n MR=exp(−ktn) 0.1 1.8 2 0.989 7 8.9×10−4 0.041 4 0.763 0.2 1.8 2 0.992 3 9.8×10−4 0.048 7 0.784 0.3 1.8 2 0.995 8 3.7×10−4 0.057 6 0.803 0.4 1.8 2 0.997 5 1.9×10−4 0.073 9 0.834 0.2 0.6 5 0.996 6 3.4×10−4 0.017 8 0.755 0.2 1.2 5 0.999 9 2.8×10−6 0.018 6 0.766 0.2 1.8 5 0.996 7 3.9×10−4 0.023 3 0.777 0.2 1.8 8 0.998 8 1.5×10−4 0.014 6 0.765 -

[1] 栗志翔.市政污泥的处置及资源化利用综述[J]. 科技风,2021(7):121-122. [2] 魏亮, 金星, 马丽萍.污水厂剩余污泥处理处置技术研究进展[J]. 农业与技术,2021,41(8):8106-8108. [3] 石万里, 张大鹏, 赵泽华, 等.化学法调理生化污泥脱水效果研究[J]. 环境工程技术学报,2020,10(2):273-279. doi: 10.12153/j.issn.1674-991X.20190114SHI W L, ZHANG D P, ZHAO Z H, et al. Study on the effect of chemical conditioning method on the dewatering effect of biochemical sludge[J]. Journal of Environmental Engineering Technology,2020,10(2):273-279. doi: 10.12153/j.issn.1674-991X.20190114 [4] 纪秀俊. CaO调质城市污泥热干化过程及其建模研究[D]. 兰州: 兰州理工大学, 2018. [5] 汪曌, 马晓茜, 彭晓为, 等.CaO改善印染污泥干化效果的微观研究[J]. 可再生能源,2016,34(3):462-468.WANG Z, MA X Q, PENG X W, et al. Microscopic study on CaO improving dryness of dyeing sludge based on directional random walk method[J]. Renewable Energy Resources,2016,34(3):462-468. [6] DENG W Y, SU Y X. Experimental study on agitated drying characteristics of sewage sludge under the effects of different additive agents[J]. Journal of Environmental Sciences,2014,26(7):1523-1529. doi: 10.1016/j.jes.2014.05.019 [7] LIU H, LIU P, HU H Y, et al. Combined effects of Fenton peroxidation and CaO conditioning on sewage sludge thermal drying[J]. Chemosphere,2014,117:559-566. doi: 10.1016/j.chemosphere.2014.09.038 [8] 丁晶, 葛仕福, 杨叙军, 等.石灰调质污泥恒温干燥特性及动力学模型研究[J]. 化工装备技术,2013,34(6):18-22. doi: 10.3969/j.issn.1007-7251.2013.06.005DING J, GE S F, YANG X J, et al. Study on isothermal drying characteristics and kinetics model of lime sludge[J]. Chemical Equipment Technology,2013,34(6):18-22. doi: 10.3969/j.issn.1007-7251.2013.06.005 [9] 章华熔, 芦佳, 叶兴联, 等.污泥热干化技术应用综述[J]. 中国环保产业,2020(1):56-59.ZHANG H R, LU J, YE X L, et al. Application and characteristic analysis on sludge thermal dewatering technology[J]. China Environmental Protection Industry,2020(1):56-59. [10] HARYANTO B, SINUHAJI T F, TARIGAN E A, et al. Simulation of natural drying kinetics of carrot (Daucus carota L.) on thickness variation[J]. IOP Conference Series:Earth and Environmental Science,2021,782(3):032086. doi: 10.1088/1755-1315/782/3/032086 [11] FORTIER J, TRUAX B, GAGNON D, et al. Natural drying and chemical characteristics of hybrid poplar firewood produced from agricultural bioenergy buffers in southern Québec, Canada[J]. Forests,2021,12(2):122. doi: 10.3390/f12020122 [12] 周登健, 林超.污泥自然干化过程中的影响因素[J]. 科技创新导报,2011,8(34):79,81. [13] 曾庆洋, 伍健东, 周兴求, 等.污泥厚度和风速对污泥常温干燥的影响及干燥模型分析[J]. 科学技术与工程,2017,17(12):55-61. doi: 10.3969/j.issn.1671-1815.2017.12.010ZENG Q Y, WU J D, ZHOU X Q, et al. Effects of sludge thickness and air velocity on sludge drying at room temperature and drying models analysis[J]. Science Technology and Engineering,2017,17(12):55-61. doi: 10.3969/j.issn.1671-1815.2017.12.010 [14] 曾庆洋, 伍健东, 周兴求, 等.石灰投加比对污泥低温干燥特性及冷凝液性质的影响[J]. 环境工程学报,2017,11(10):5603-5608. doi: 10.12030/j.cjee.201611158ZENG Q Y, WU J D, ZHOU X Q, et al. Effects of lime addition ratio on sludge lime drying at low temperature and the properties of condensate[J]. Chinese Journal of Environmental Engineering,2017,11(10):5603-5608. doi: 10.12030/j.cjee.201611158 [15] 曹秀芹, 杨华, 甘一萍, 等.污泥石灰干化作用机理及应用研究[J]. 水工业市场,2011(8):44-48. [16] 冯凯, 黄鸥.石灰调质与石灰干化工艺在污泥脱水中的应用[J]. 给水排水,2011,47(5):7-10. doi: 10.3969/j.issn.1002-8471.2011.05.002 [17] 闫景武, 杨朝晖, 黄兢, 等.添加CaO脱水污泥的微波干燥特性[J]. 环境工程学报,2016,10(9):5128-5132. doi: 10.12030/j.cjee.201504069YAN J W, YANG Z H, HUANG J, et al. Microwave drying characteristics and kinetic model of thin-layer dehydrated sludge with CaO addition[J]. Chinese Journal of Environmental Engineering,2016,10(9):5128-5132. doi: 10.12030/j.cjee.201504069 [18] 梁晓辉, 司洪宇, 赵玉晓, 等.市政剩余污泥CaO处理及生物干化过程的细菌群落变化[J]. 山东科学,2020,33(6):72-78. doi: 10.3976/j.issn.1002-4026.2020.06.010 [19] 吴生礼, 陶乐仁, 谷志攀, 等.污泥薄层干燥特性及动力学模型分析[J]. 净水技术,2017,36(12):33-37.WU S L, TAO L R, GU Z P, et al. Characteristics of thin-layer drying and analysis of kinetic model for sewage sludge[J]. Water Purification Technology,2017,36(12):33-37. [20] 冯金钻, 陶乐仁, 黄理浩, 等.市政污泥干燥特性的实验研究和模拟分析[J]. 能源研究与信息,2021,37(1):10-16.FENG J Z, TAO L R, HUANG L H, et al. Experimental study and simulation analysis on drying characteristics of municipal sludge[J]. Energy Research and Information,2021,37(1):10-16. [21] 孔令波, 杨兴, 董继先, 等.造纸污泥薄层干燥模型的研究进展[J]. 中国造纸,2019,38(11):70-75. doi: 10.11980/j.issn.0254-508X.2019.11.011KONG L B, YANG X, DONG J X, et al. Research progress of thin-layer drying model for paper sludge[J]. China Pulp & Paper,2019,38(11):70-75. doi: 10.11980/j.issn.0254-508X.2019.11.011 [22] 张绪坤, 刘胜平, 吴青荣, 等.污泥低温干燥动力学特性及干燥参数优化[J]. 农业工程学报,2017,33(17):216-223. doi: 10.11975/j.issn.1002-6819.2017.17.029ZHANG X K, LIU S P, WU Q R, et al. Drying kinetics and parameters optimization of sludge drying at low temperature[J]. Transactions of the Chinese Society of Agricultural Engineering,2017,33(17):216-223. doi: 10.11975/j.issn.1002-6819.2017.17.029 [23] ERBAY Z, ICIER F. A review of thin layer drying of foods: theory modeling, and experimental results[J]. Critical Reviews in Food Science and Nutrition,2010,50(5):441-464. doi: 10.1080/10408390802437063 [24] PAGE G E. Factors influencing the maximum rates of air drying shelled corn in thin layers[D]. West Lafayette: Purdue University, 1949. [25] HENDORSON S M, PABIS S. Grain drying theory: I. temperature effect on drying coefficient[J]. Journal of Agricultural Engineering Research,1961,6(3):169. [26] JUN H L, HUI J K. Vacuum drying kinetics of Asian white radish (Raphanus sativus L.) slices[J]. Food Science and Technology,2008,42(1):180-186. [27] ERTEKIN C, YALDIZ O. Drying of eggplant and selection of a suitable thin layer drying model[J]. Food Engineer,2004,63:349-359. ⊗ doi: 10.1016/j.jfoodeng.2003.08.007 -

下载:

下载: