Application of a new-type double medium pneumatic atomization spray system in odour treatment in a municipal wastewater treatment plant

-

摘要:

以城市污水厂格栅间为研究对象,在分析恶臭气体产生特性的基础上,研发出新型双介质气动雾化喷淋系统,并对系统运行参数进行了优化。将该系统应用于北京市某城市污水厂格栅间,考察了其对硫化氢和氨的去除效果。结果表明,该系统对污水厂格栅间的硫化氢和氨的去除率分别为90.54%~97.80%和93.75%~99.42%,取得了较好的除臭效果。该系统投资费用为95万元,运行费用为3.62万元/a,其中水费占运行费用的51.10%。新型双介质气动雾化喷淋系统较好适用于城市污水厂分散点源恶臭气体的原位处理。

Abstract:Taking the screen room in municipal sewage treatment plants (MSTPs) as the object, a new-type double medium pneumatic atomization spray system was developed based on the characterisctics of odour from scattered sources in MSTPs, and the operating parameters of the system were optimized. The system was applied in a MSTP in Beijing and its performence was studied. The results showed that the removal efficiency of hydrogen sulfide and ammonia in the screen room were 90.54%-97.80% and 93.75%-99.42%, respectively with a good deodorization effect. The investment cost of the system was 950 000 yuan, and the operating cost was 36 200 yuan/a. The water cost accounted for 51.10% of the operating cost. The new-type double medium pneumatic atomization spray system is suitable for the in-situ treatment of odour from scattered sources in MSTPs.

-

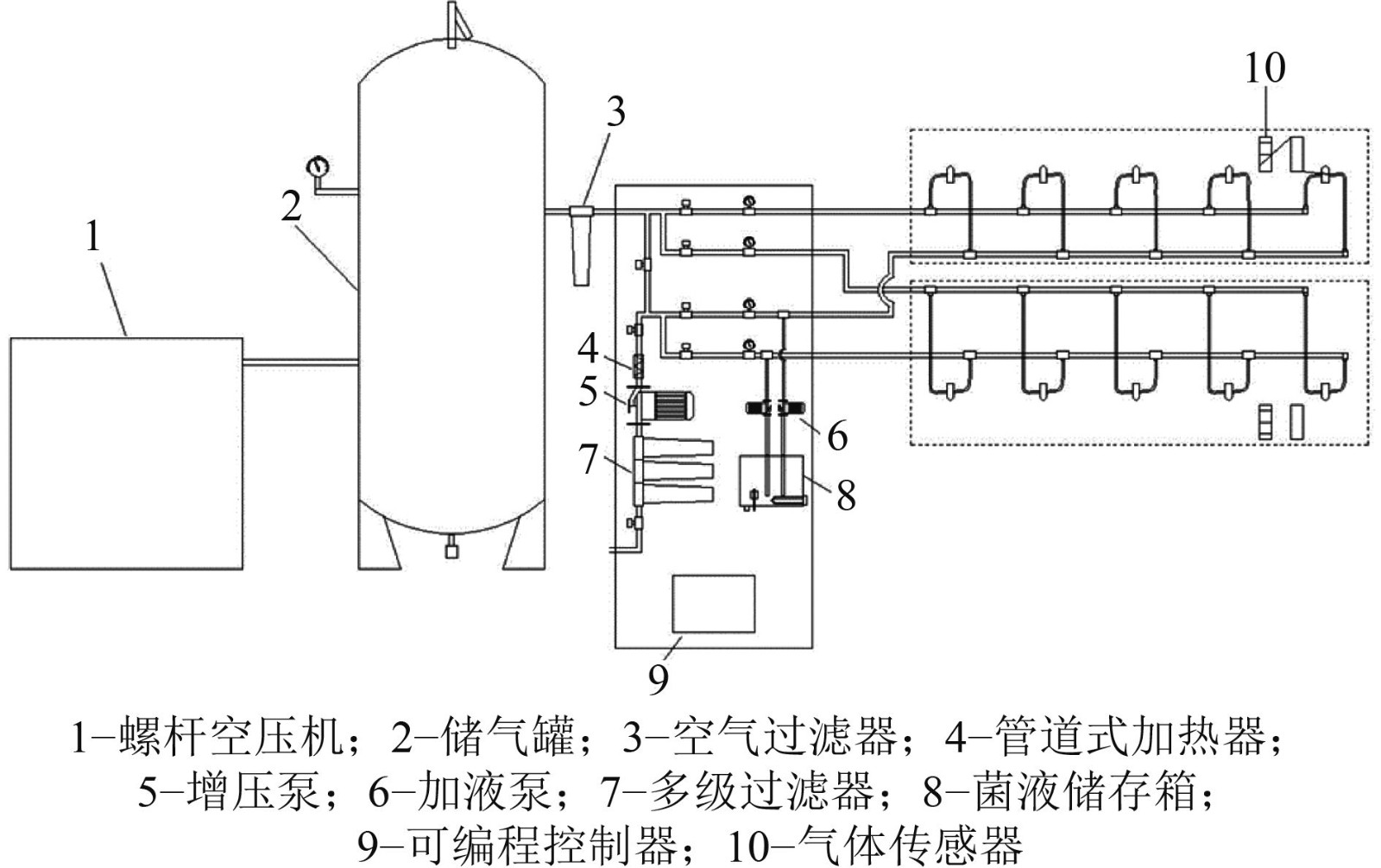

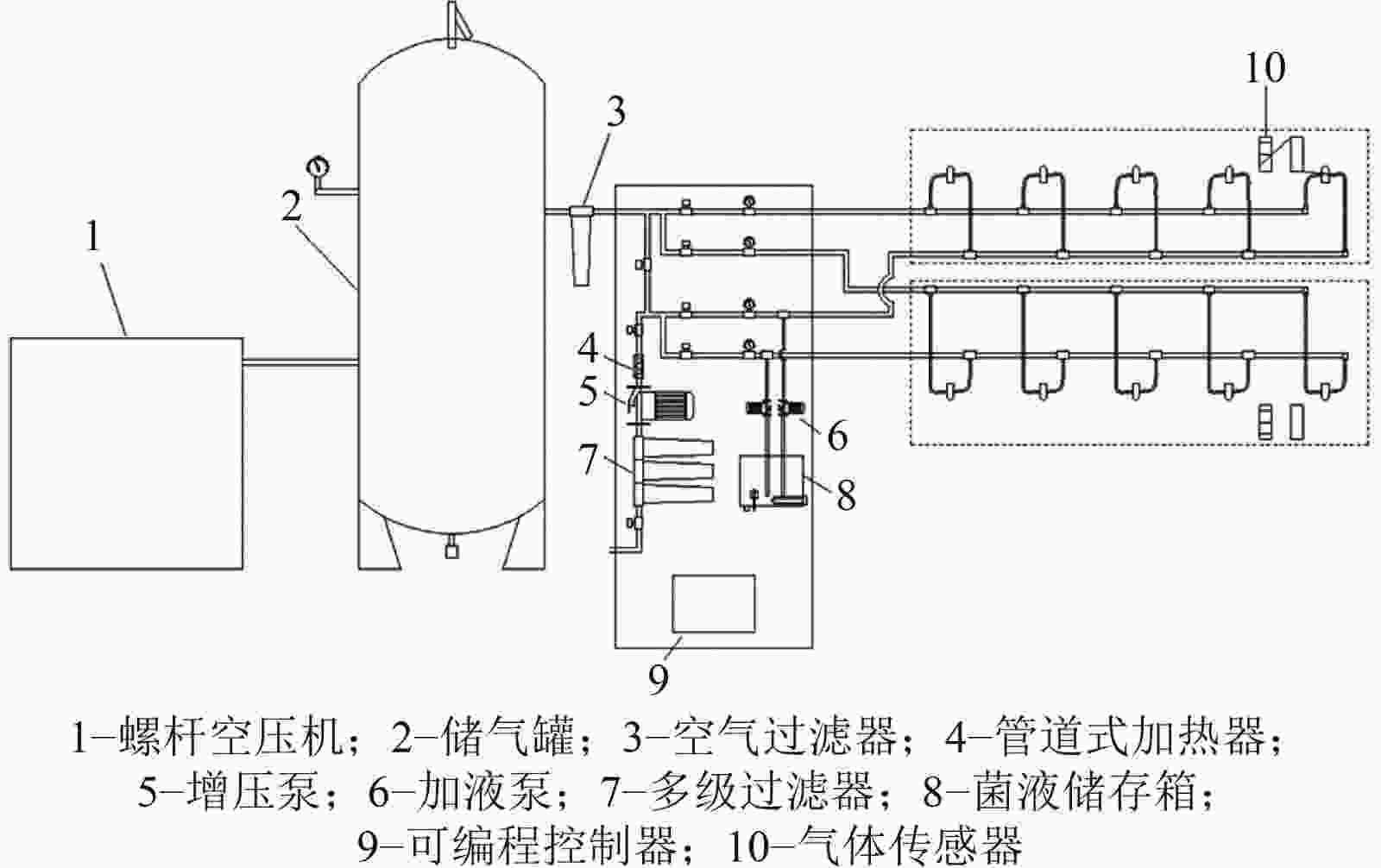

表 1 双介质气动雾化喷淋系统主要部件及参数

Table 1. Main components and parameters of the double medium pneumatic atomization spray system

部件 数量/个 设计参数 设备主体 1 长×宽×高为90 cm×70 cm×130 cm 多级过滤器 1 三级PPF滤芯 加液泵 1 可调配比例为0.1%~10% 菌液储存箱 1 容积为20 L 增压泵 1 压力为100~300 kPa,流量为1~3 m³/h 管道式加热器 1 加热温度为10~40 ℃ 螺杆空压机 1 螺杆式,产气量≥1 000 L/min 储气罐 1 立式,容积为300 L 空气过滤器 1 滤芯有效过滤面积为0.01 m2 超声雾化喷头 12~18 产雾量为2.8~4.2 L/h 表 2 某城市污水厂格栅间产生的硫化氢和氨浓度

Table 2. Concentration of hydrogen sulfide and ammonia produced in screen room in a MSTP

mg/m3 格栅状态 硫化氢 氨 浓度 平均浓度 浓度 平均浓度 运行时 0.03~1.58 0.23±0.02 0~5.47 3.32±0.24 停止运行后1 h 0.01~0.18 0.04±0.01 0~0.23 0.14±0.02 表 3 不同孔径雾化喷头的喷雾压力和喷雾流量

Table 3. Spraying pressure and spraying flow of spraying nozzles with different apertures

编号 孔径/mm 喷雾压力/(kg/cm2) 喷雾流量/(mL/min) 1# 0.15 15~90 20~46 2# 0.20 15~90 49~89 3# 0.30 10~90 80~145 4# 0.40 10~90 95~178 5# 0.50 10~90 130~243 表 4 双介质气动雾化喷淋系统对硫化氢和氨的去除率

Table 4. Removal efficiency of hydrogen sulfide and ammonia by the double medium pneumatic atomization spray system

运行时间/d 硫化氢 氨 喷淋前浓度/(mg/m3) 喷淋后浓度/(mg/m3) 去除率/% 喷淋前浓度/(mg/m3) 喷淋后浓度/(mg/m3) 去除率/% 1 1.26 0.05 96.20 1.58 0.10 93.76 8 0.69 0.03 95.45 2.65 0.16 94.14 17 0.27 0.01 97.70 0.88 0.05 94.04 26 1.09 0.07 93.16 3.32 0.09 97.33 33 1.37 0.10 92.94 2.77 0.13 95.45 41 1.48 0.06 95.68 2.34 0.13 94.33 50 1.26 0.05 96.32 2.68 0.11 96.08 57 0.97 0.07 93.04 3.14 0.09 97.10 65 1.13 0.11 90.54 3.02 0.15 95.13 75 0.87 0.05 94.07 2.89 0.14 95.00 83 1.13 0.02 97.80 2.57 0.03 98.78 92 1.51 0.11 92.78 2.47 0.15 93.75 100 0.89 0.07 91.92 3.08 0.19 93.98 109 0.74 0.07 90.67 3.16 0.02 99.42 120 1.46 0.11 92.46 3.97 0.23 94.20 表 5 双介质气动雾化喷淋系统的投资费用

Table 5. Investment costs of the double medium pneumatic atomization spray system

万元 项目 费用 备注 设备工程 40 过滤单元、自动配比系统、增压系统、

自保护组件及其安装费用电气工程 20 智能控制系统、电器和电缆等费用 喷淋管线 20 内置管路系统、喷雾管路系统等费用 其他费用 15 安装和辅助材料等费用 合计 95 表 6 双介质气动雾化喷淋系统的运行费用

Table 6. Operating costs of the double medium pneumatic atomization spray system

项目 单位费用 总费用/

(万元/a)备注 电费 1.0元/(kW·h) 0.02 循环水泵功率为2.2 kW 水费 8.0元/m3 1.85 用水量为6.33 m3/d 除臭菌剂费 400元/m3 1.75 除臭菌剂使用量为0.015 m3/d 合计 3.62 -

[1] 李娟, 李金香, 杨妍妍.城镇污水处理厂污泥泥质监测及资源化风险评价[J]. 环境科学,2021,42(4):1956-1966.LI J, LI J X, YANG Y Y. Characteristics of sludge and associated risk assessment of urban sewage treatment plants[J]. Environmental Science,2021,42(4):1956-1966. [2] LI P Y, LI L, WANG Y J, et al. Characterization, factors, and UV reduction of airborne bacteria in a rural wastewater treatment station[J]. Science of the Total Environment,2021,751:141811. doi: 10.1016/j.scitotenv.2020.141811 [3] 杨庆, 李洋, 崔斌, 等.城市污水处理过程中恶臭气体释放的研究进展[J]. 环境科学学报,2019,39(7):2079-2087.YANG Q, LI Y, CUI B, et al. Research advances of odor released from municipal wastewater treatment process[J]. Acta Scientiae Circumstantiae,2019,39(7):2079-2087. [4] 翟增秀, 李伟芳, 邹克华, 等.愉悦度在恶臭污染感官评价中的应用[J]. 环境工程技术学报,2018,8(5):546-550.ZHAI Z X, LI W F, ZOU K H, et al. The application of hedonic tone in odour pollution sensory evaluation[J]. Journal of Environmental Engineering Technology,2018,8(5):546-550. [5] 夏湘勤, 席北斗, 黄彩红, 等.畜禽粪便堆肥臭气控制研究进展[J]. 环境工程技术学报,2019,9(6):649-657. doi: 10.12153/j.issn.1674-991X.2019.05.142XIA X Q, XI B D, HUANG C H, et al. Review on odor control of livestock and poultry manure composting[J]. Journal of Environmental Engineering Technology,2019,9(6):649-657. doi: 10.12153/j.issn.1674-991X.2019.05.142 [6] LI R Y, HAN Z L, SHEN H Z, et al. Volatile sulfur compound emissions and health risk assessment from an A2/O wastewater treatment plant[J]. Science of the Total Environment,2021,794:148741. doi: 10.1016/j.scitotenv.2021.148741 [7] 韩彩云, 张晶宇, 丁永伟, 等.曝气沉砂池H2S排放浓度的时间变化与影响因子[J]. 中国给水排水,2020,36(7):74-77.HAN C Y, ZHANG J Y, DING Y W, et al. Temporal variation characteristics and influencing factors of H2S emission concentration in aerated grit chamber[J]. China Water & Wastewater,2020,36(7):74-77. [8] HU X R, HAN M F, WANG C, et al. A short review of bioaerosol emissions from gas bioreactors: healththreats, influencing factors and control technologies[J]. Chemosphere,2020,253:126737. doi: 10.1016/j.chemosphere.2020.126737 [9] 黄力华, 刘建伟, 夏雪峰, 等.城市污水处理厂典型气体污染物产生特性研究[J]. 科学技术与工程,2015,15(3):295-299. doi: 10.3969/j.issn.1671-1815.2015.03.059HUANG L H, LIU J W, XIA X F, et al. Research of emission characteristics of gaseous pollutants in municipal wastewater treatment plant[J]. Science Technology and Engineering,2015,15(3):295-299. doi: 10.3969/j.issn.1671-1815.2015.03.059 [10] 赵茹涵,杨庆,彭赵旭,等.城市污水处理厂挥发性硫化物的释放特征与风险评价[J/OL]. 中国环境科学. doi: 10.19674/j.cnki.issn1000-6923.20210708.001.ZHAO R H,YANG Q,PENG Z X,et al.Release characteristics and risks evaluation of VSCs in municipal wastewater treatment plants [J/OL]. 中国环境科学. doi: 10.19674/j.cnki.issn1000-6923.20210708.001. [11] CODOLO M C, BIZZO W A. Experimental study of the SO2 removal efficiency and volumetric mass transfer coefficients in a pilot-scale multi-nozzle spray tower[J]. International Journal of Heat and Mass Transfer,2013,66:80-89. doi: 10.1016/j.ijheatmasstransfer.2013.07.011 [12] BEŠENIĆ T, BALETA J, PACHLER K, et al. Numerical modelling of sulfur dioxide absorption for spray scrubbing[J]. Energy Conversion and Management,2020,217:112762. doi: 10.1016/j.enconman.2020.112762 [13] EJIM C E, RAHMAN M A, AMIRFAZLI A, et al. Effects of liquid viscosity and surface tension on atomization in two-phase, gas/liquid fluid coker nozzles[J]. Fuel,2010,89(8):1872-1882. doi: 10.1016/j.fuel.2010.03.005 [14] WANG Y C, HAN M F, JIA T P, et al. Emissions, measurement, and control of odor in livestock farms: a review[J]. Science of the Total Environment,2021,776:145735. doi: 10.1016/j.scitotenv.2021.145735 [15] 空气和废气监测分析方法[M]. 4版. 北京: 中国环境科学出版社, 2003. [16] YANG K X, LI L, WANG Y J, et al. Airborne bacteria in a wastewater treatment plant: Emissioncharacterization, source analysis and health risk assessment[J]. Water Research,2019,149:596-606. doi: 10.1016/j.watres.2018.11.027 [17] POCHWAT, KIDA, ZIEMBOWICZ, et al. Odours in sewerage: a description of emissions and of technical abatement measures[J]. Environments,2019,6(8):89. doi: 10.3390/environments6080089 [18] LU F, HU T Y, WEI S Y, et al. Bioaerosolization behavior along sewage sludge biostabilization[J]. Frontiers of Environmental Science & Engineering,2020,15(3):1-14. [19] 李心月, 郑昀, 李洪枚, 等.城市污水处理厂空气硫化氢和氨初步健康风险评估[J]. 环境与健康杂志,2020,37(2):178-181.LI X Y, ZHENG Y, LI H M, et al. Health risk assessment of hydrogen sulfide and ammonia in air of municipal wastewater treatment plant[J]. Journal of Environment and Health,2020,37(2):178-181. [20] LIU Z Q, NIE W, PENG H T, et al. The effects of the spraying pressure and nozzle orifice diameter on the atomizing rules and dust suppression performances of an external spraying system in a fully-mechanized excavation face[J]. Powder Technology,2019,350:62-80. doi: 10.1016/j.powtec.2019.03.029 [21] 刘建伟, 高柳堂, 韩昌福, 等.养殖场典型功能区恶臭气体处理工艺选择与工程实例[J]. 安全与环境工程,2019,26(3):109-114.LIU J W, GAO L T, HAN C F, et al. Process selection and engineering example of odorous gas treatment in typical functional areas of farm[J]. Safety and Environmental Engineering,2019,26(3):109-114. [22] YANG S B, NIE W, LÜ S S, et al. Effects of spraying pressure and installation angle of nozzles on atomization characteristics of external spraying system at a fully-mechanized mining face[J]. Powder Technology,2019,343:754-764. □ doi: 10.1016/j.powtec.2018.11.042 -

下载:

下载: