Pollution characteristics and effect of integrated treatment technology of solid wastes from water-based drilling for natural gas exploitation: taking Sulige Gas Field as an example

-

摘要:

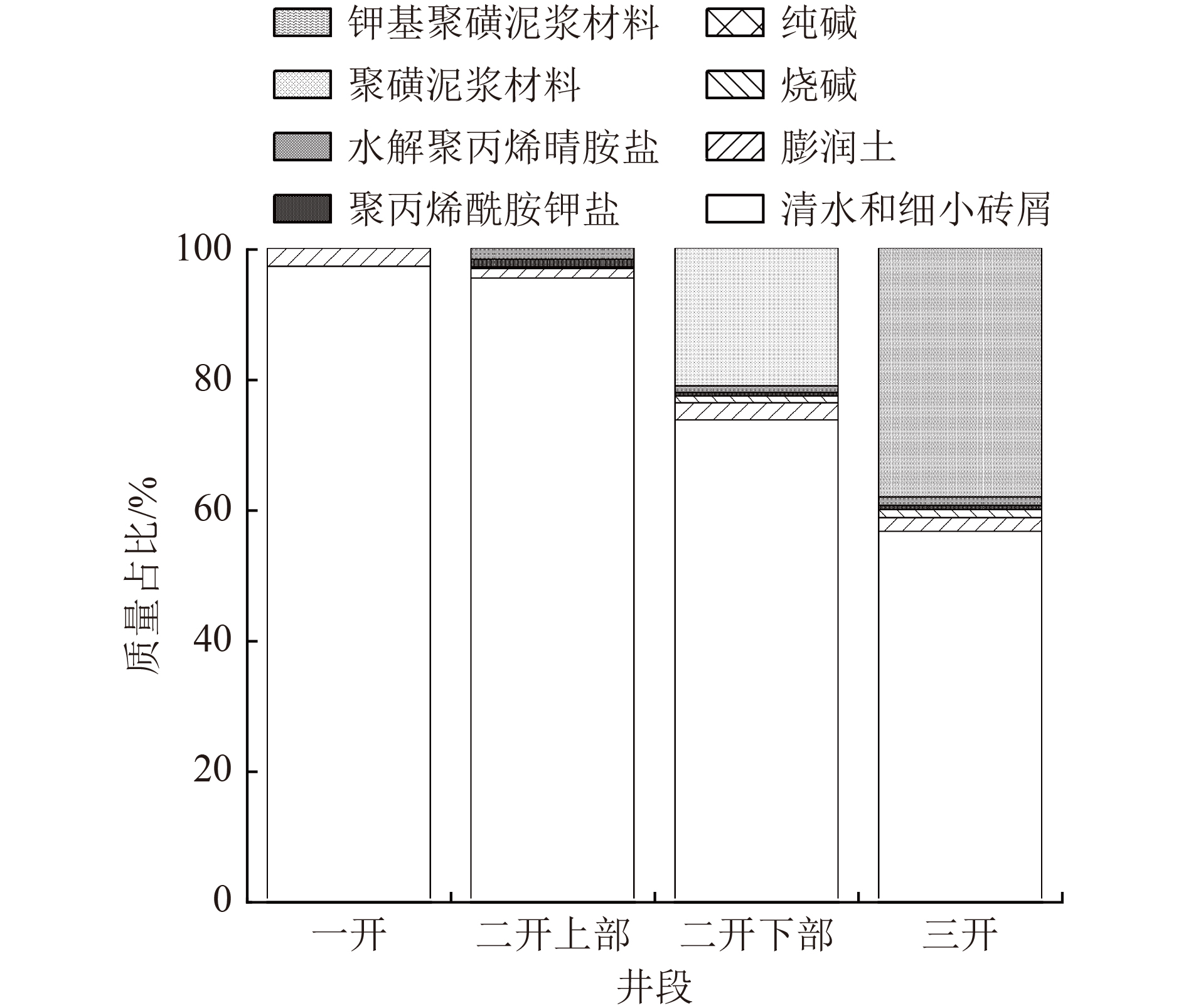

天然气开采过程产生大量的钻井固体废物,其中含有石油烃、无机盐及难降解有机物等有毒有害物质。对苏里格气田5个区块典型钻井现场不同井型、不同井段产生的固体废物进行采样,分析其性能特征、污染特点,研究钻井固体废物分类管控—稳定化预处理—高温氧化一体化处理技术工艺参数,分析利用该技术工艺处理前后钻井固体废物污染物浓度变化情况。结果表明:通过精细化的稳定化预处理技术处理,浅表层钻井固体废物及浸出液中,污染物浓度符合GB 8978—1996《污水综合排放标准》最高允许限值要求;深层井段钻井固体废物中石油烃的削减率均在98.6%以上,浓度符合GB 36600—2018《土壤环境质量 建设用地土壤污染风险管控标准(试行)》建设用地土壤污染第二类用地筛选值要求,残渣中重金属和有机物浓度显著降低,符合GB 8978—1996《污水综合排放标准》限值要求。另外,固体废物体积缩减41.2%。该一体化处理技术可从源头上解决天然气开采钻井固体废物处理处置问题,与现有传统不分类处理技术相比较,整体成本降低52%,具有较好的推广前景。

Abstract:shIn the process of natural gas exploitation, a large amount of drilling solid wastes are produced, which contains toxic and harmful substances such as petroleum hydrocarbon, inorganic salt and refractory organic matter. The solid wastes produced by different well types, different well sections at typical drilling sites in five blocks of Sulige Gas Field were sampled, their performance characteristics and pollution characteristics were analyzed, the technical parametshers of the integrated process of classified management and control, stabilization pretreatment and high-temperature incineration and oxidation of drilling solid wastes were studied, and the variations of drilling solid waste pollutant concentration before and after treatment with this technology were analyzed. The results showed that the concentrations of pollutants in the solid wastes and leachates of shallow surface drilling met the requirements of the maximum allowable limits of Integrated Wastewater Discharge Standard (GB 8978-1996) after treatment by fine stabilization pretreatment technology. The reduction rate of petroleum hydrocarbons in drilling solid wastes in the deep well section was more than 98.6%, and the concentrations met the screening value requirements of category Ⅱ of construction land soil pollution in Soil Environmental Quality Risk Control Standard for Soil Contamination of Development Land (GB 36600-2018). In the meanwhile, the concentrations of heavy metals and organic matter in the residue decreased significantly, which were in line with the limit requirements of GB 8978-1996. Moreover, the volume of solid wastes was reduced by 41.2%. The integrated treatment technology of ‘classified control-stabilization pretreatment-high temperature oxidation’ could solve the problem of solid wastes treatment and disposal of natural gas exploitation and drilling from the source. Compared with the existing traditional unclassified treatment technologies, the overall cost of the integrated technology was reduced by 52%, which had a good prospect for promotion.

-

表 1 钻井固体废物样品的石油烃浓度及pH

Table 1. Petroleum hydrocarbons content and pH of drilling solid waste samples

钻井固体废物 样品编号 石油烃浓度/(mg/kg) pH 浅表层井段 1 828 9.41 2 952 9.50 3 536 9.47 4 738 9.62 5 822 9.45 深层井段 6 6 390 9.82 7 6 120 9.94 8 7 200 10.05 9 9 120 10.12 10 7 120 9.78 -

[1] 杨德敏, 袁建梅, 程方平, 等.油气开采钻井固体废物处理与利用研究现状[J]. 化工环保,2019,39(2):129-136. doi: 10.3969/j.issn.1006-1878.2019.02.003YANG D M, YUAN J M, CHENG F P, et al. Current situation of treatment and utilization of drilling solid waste in oil and gas exploitation[J]. Environmental Protection of Chemical Industry,2019,39(2):129-136. doi: 10.3969/j.issn.1006-1878.2019.02.003 [2] 李开环. 涪陵地区页岩气开采固体废物污染特性及资源化环境风险研究[D]. 重庆: 重庆交通大学, 2018. [3] 王之超, 何洁, 张曼丽, 等.油基钻井岩屑固化体中多环芳烃释放特征[J]. 环境工程技术学报,2020,10(4):647-652. doi: 10.12153/j.issn.1674-991X.20200013Zhichao WANG, Jie HE, Manli ZHAN, et al. Release characteristics of PAHs in oil-based drilling cuttings solidified body[J]. Journal of Environmental Engineering Technology,2020,10(4):647-652. doi: 10.12153/j.issn.1674-991X.20200013 [4] 吴明霞. 废弃水基钻井液环境影响及固化处理技术研究[D]. 大庆: 东北石油大学, 2012. [5] 罗伟. 钻井废弃泥浆固化路基材料性能研究[D]. 成都: 西南石油大学, 2015. [6] 童刚强. 川东北地区钻井固废的处置研究[D]. 成都: 西南交通大学, 2014. [7] 王松, 刘罡, 李谷.江汉油田废弃水基钻井液对环境的影响研究[J]. 油气田环境保护,1998(3):30-32.WANG S, LIU G, LI G. Research on the effect of abandoned water-based drilling fluid upon environment in Jianghan oilfield[J]. Environmental Protection of Oil & Gas Fields,1998(3):30-32. [8] 王茂仁. 新疆油田钻井水基固液废弃物不落地处理技术研究[D]. 成都: 西南石油大学, 2017: 3-5. [9] 张媛媛, 祝威, 王利君.油气田企业固体废物处理处置及资源化技术展望[J]. 油气田环境保护,2018,28(1):1-3. doi: 10.3969/j.issn.1005-3158.2018.01.001ZHANG Y Y, ZHU W, WANG L J. Prospect of oily solid waste treatment and resource utilization technology in oil and gas field enterprises[J]. Environmental Protection of Oil & Gas Fields,2018,28(1):1-3. doi: 10.3969/j.issn.1005-3158.2018.01.001 [10] 杜春蕾. 油田钻井废弃泥浆中重金属分布特征与污染评价 : 以中石油塔里木分公司塔北井区为例[D]. 乌鲁木齐: 新疆大学, 2015: 1-2. [11] KOGBARA R B, DUMKHANA B B, AYOTAMUNO J M, et al. Recycling stabilised/solidified drill cuttings for forage production in acidic soils[J]. Chemosphere,2017,184:652-663. doi: 10.1016/j.chemosphere.2017.06.042 [12] SERRANO S, VLASSOPOULOS D, BESSINGER B, et al. Immobilization of Hg(Ⅱ) by coprecipitation in sulfate-cement systems[J]. Environmental Science & Technology,2012,46(12):6767-6775. [13] KUMPIENE J, LAGERKVIST A, MAURICE C. Stabilization of As, Cr, Cu, Pb and Zn in soil using amendments: a review[J]. Waste Management,2008,28(1):215-225. doi: 10.1016/j.wasman.2006.12.012 [14] IRYNA A, LEONID P. The immobilization of heavy metals during drilling sludge utilization[J]. Environmental Technology & Innovation,2016,6:123-131. [15] 何敏, 张思兰, 张春, 等.钻井与热脱附过程对油基泥浆中矿物油组分变化的影响[J]. 环境工程技术学报,2018,8(3):290-296. doi: 10.3969/j.issn.1674-991X.2018.03.038HE M, ZHANG S L, ZHANG C, et al. Effects of drilling and thermal desorption process on the change of mineral oil compositions in oil-based mud[J]. Journal of Environmental Engineering Technology,2018,8(3):290-296. doi: 10.3969/j.issn.1674-991X.2018.03.038 [16] WAN S Y, YU S Y, HE T P, et al. Application of microbial treatment on waterbased drilling waste[J]. Environmental Protection of Oil & Gas Fields,2019,29(2):33-36. [17] 李世刚, 吴明霞, 王宝辉, 等.废弃油基钻井液处理技术研究进展[J]. 化学工业与工程技术,2012,33(5):33-37.LI S G, WU M X, WANG B H, et al. Research progress on treating technology of waste oil-based drilling fluid[J]. Journal of Chemical Industry & Engineering,2012,33(5):33-37. [18] SANTOS N B C, FAGUNDES F M, de OLIVEIRA AROUCA F, et al. Sedimentation of solids in drilling fluids used in oil well drilling operations[J]. Journal of Petroleum Science and Engineering,2018,162:137-142. doi: 10.1016/j.petrol.2017.12.026 [19] FENG D, LORENZEN L, ALDRICH C, et al. Ex situ diesel contaminated soil washing with mechanical methods[J]. Minerals Engineering,2001,14(9):1093-1100. doi: 10.1016/S0892-6875(01)00114-5 [20] CONNER J R, HOEFFNER S L. A critical review of stabilization/solidification technology[J]. Critical Reviews in Environmental Science and Technology,1998,28(4):397-462. doi: 10.1080/10643389891254250 [21] 苏勤, 何青水, 张辉, 等.国外陆上钻井废弃物处理技术[J]. 石油钻探技术,2010,38(5):106-110.SU Q, HE Q S, ZHANG H, et al. Foreign onshore drilling waste treatment technology[J]. Petroleum Drilling Techniques,2010,38(5):106-110. [22] 韩桂梅, 周长波, 方刚, 等.天然气开采钻井固体废物处理处置及资源化技术的应用现状及展望[J]. 环境工程技术学报,2021,11(3):583-590.HAN G M, ZHOU C B, FANG G, et al. Application status and prospects of solid waste disposal and resource utilization technology in natural gas extraction drilling[J]. Journal of Environmental Engineering Technology,2021,11(3):583-590. [23] 生态环境部, 国家市场监督管理总局. 土壤环境质量 建设用地土壤污染风险管控标准: GB 36600—2018[S]. 北京: 中国标准出版社, 2018. [24] ORESHKIN D V, CHEBOTAEV A N, PERFILOV V A. Disposal of drilling sludge in the production of building materials[J]. Procedia Engineering,2015,111:607-611. doi: 10.1016/j.proeng.2015.07.053 [25] 王朝强, 林晓燕, 梅绪东, 等. 我国页岩气开采钻井岩屑处理处置现状: 以重庆地区为例[C]. 2017油气田勘探与开发国际会议(IFEDC2017)论文集, 2017. [26] 吕倩楠.大牛地气田水基钻井岩屑危险特性鉴别[J]. 石油与天然气化工,2018,47(5):112-116.LYU Q N. Research on hazard identification of water-based drilling cuttings in Daniudi gas field[J]. Chemical Engineering of Oil & Gas,2018,47(5):112-116. [27] 龚选波, 王广才.石油烃污染场地健康风险评价[J]. 中国水利技术信息中心,2009,6:127-132. [28] 丁安军, 王雨辰, 廖长君, 等.钻井含油污泥高温热解处理技术研究应用[J]. 石油地质与工程,2018,32(5):119-120. doi: 10.3969/j.issn.1673-8217.2018.05.032DING A J, WANG Y C, LIAO C J, et al. Study and application of high temperature pyrolysis technology for drilling oily sludge[J]. Petroleum Geology and Engineering,2018,32(5):119-120. doi: 10.3969/j.issn.1673-8217.2018.05.032 [29] 黄慧, 聂志强, 孟棒棒, 等.不同处理工艺页岩气钻井岩屑的污染特性[J]. 环境科学研究,2020,33(3):777-782.HUANG H, NIE Z Q, MENG B B, et al. Pollution characteristics of typical field shale gas drilling cuttings with different treatment processes[J]. Research of Environmental Sciences,2020,33(3):777-782. [30] 黄思雨, 王嫣云, 周博逊, 等.页岩气开发油基钻屑-单组分生物质共热解特性[J]. 环境科学研究,2019,32(6):1074-1080.HUANG S Y, WANG Y Y, ZHOU B X, et al. Co-pyrolysis characteristics of oil-based drill cuttings and one-component biomass in shale gas exploitation[J]. Research of Environmental Sciences,2019,32(6):1074-1080. [31] 王丽芳. 废弃油基钻屑焚烧处理特征研究[D]. 西安: 陕西科技大学, 2017. [32] 宋薇, 刘建国, 聂永丰.含油污泥组成及其对热解特性的影响[J]. 环境科学,2008,29(7):2063-2067. doi: 10.3321/j.issn:0250-3301.2008.07.051SONG W, LIU J G, NIE Y F. Components of oil sludge and their influence on pyrolysis behaviors[J]. Environmental Science,2008,29(7):2063-2067. doi: 10.3321/j.issn:0250-3301.2008.07.051 [33] WANG X D, LI C X, ZHANG B, et al. Migration and risk assessment of heavy metals in sewage sludge during hydrothermal treatment combined with pyrolysis[J]. Bioresource Technology,2016,221:560-567. doi: 10.1016/j.biortech.2016.09.069 [34] DE LUAN J, LI A M, SU T, et al. Translocation and toxicity assessment of heavy metals from circulated fluidized-bed combustion of oil shale in Huadian, China[J]. Journal of Hazardous Materials,2009,166(2/3):1109-1114. ⊕ -

下载:

下载: