Characteristics and environmental impact of VOCs and greenhouse gas emissions from ground flares of typical petrochemical enterprises

-

摘要:

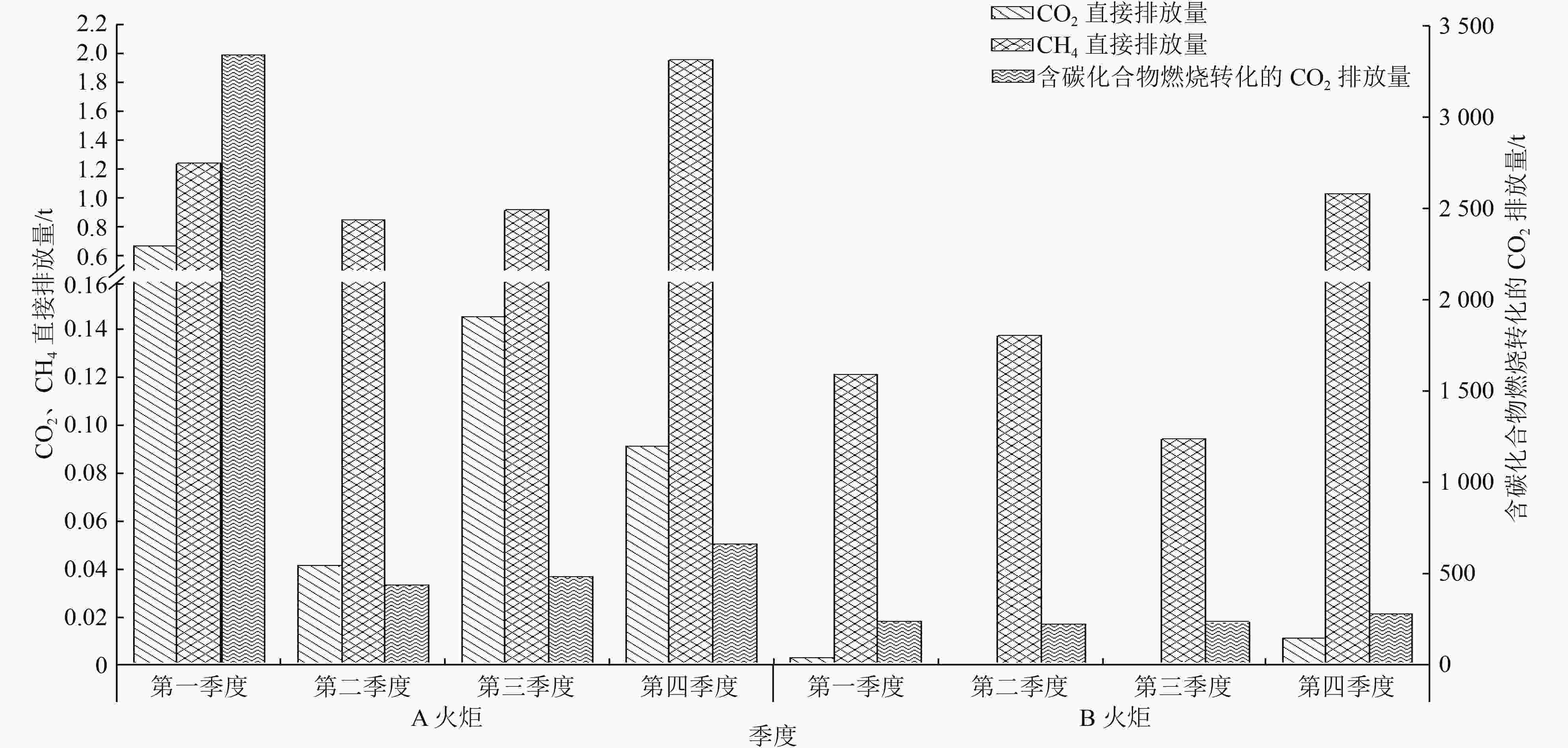

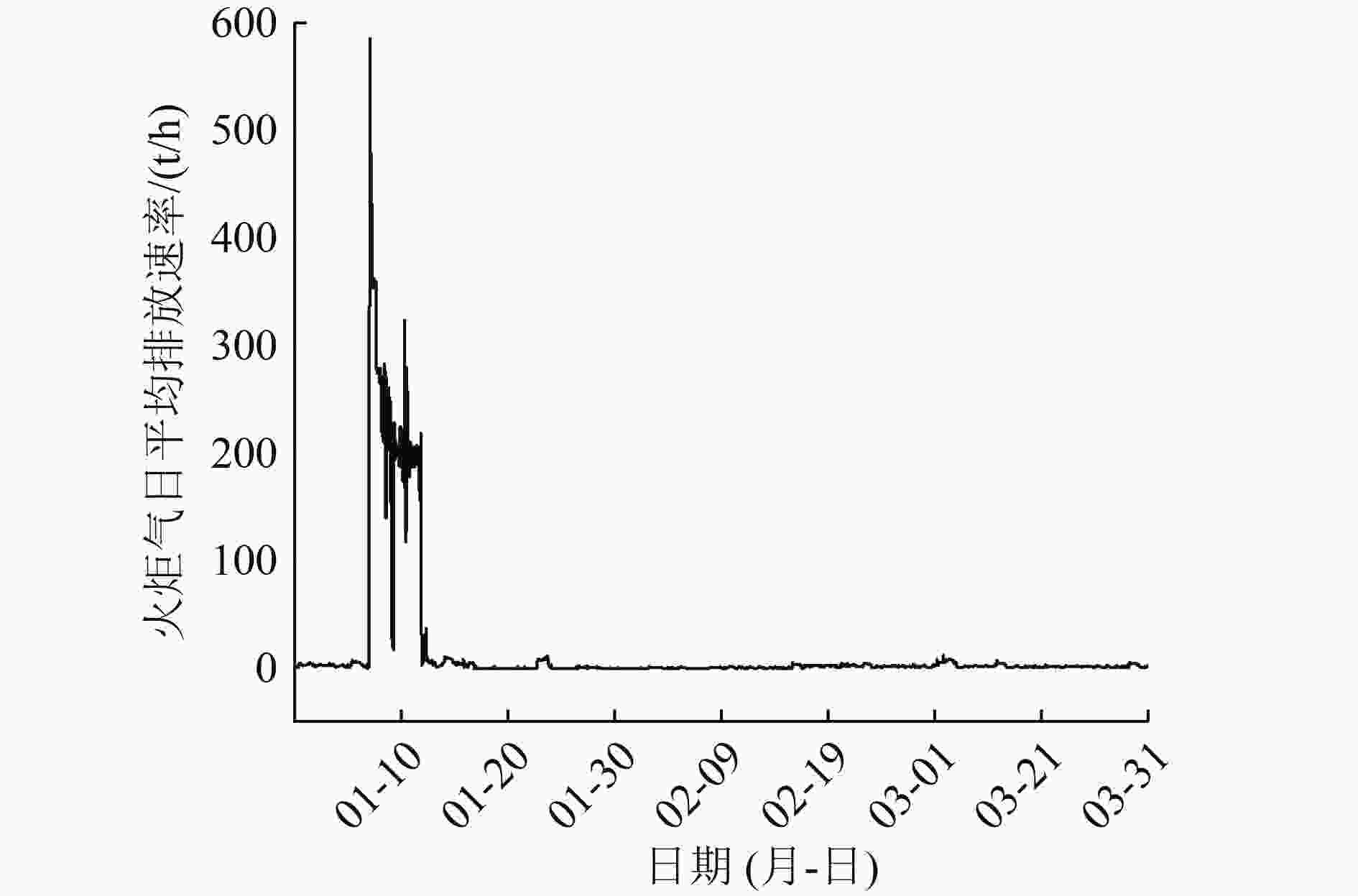

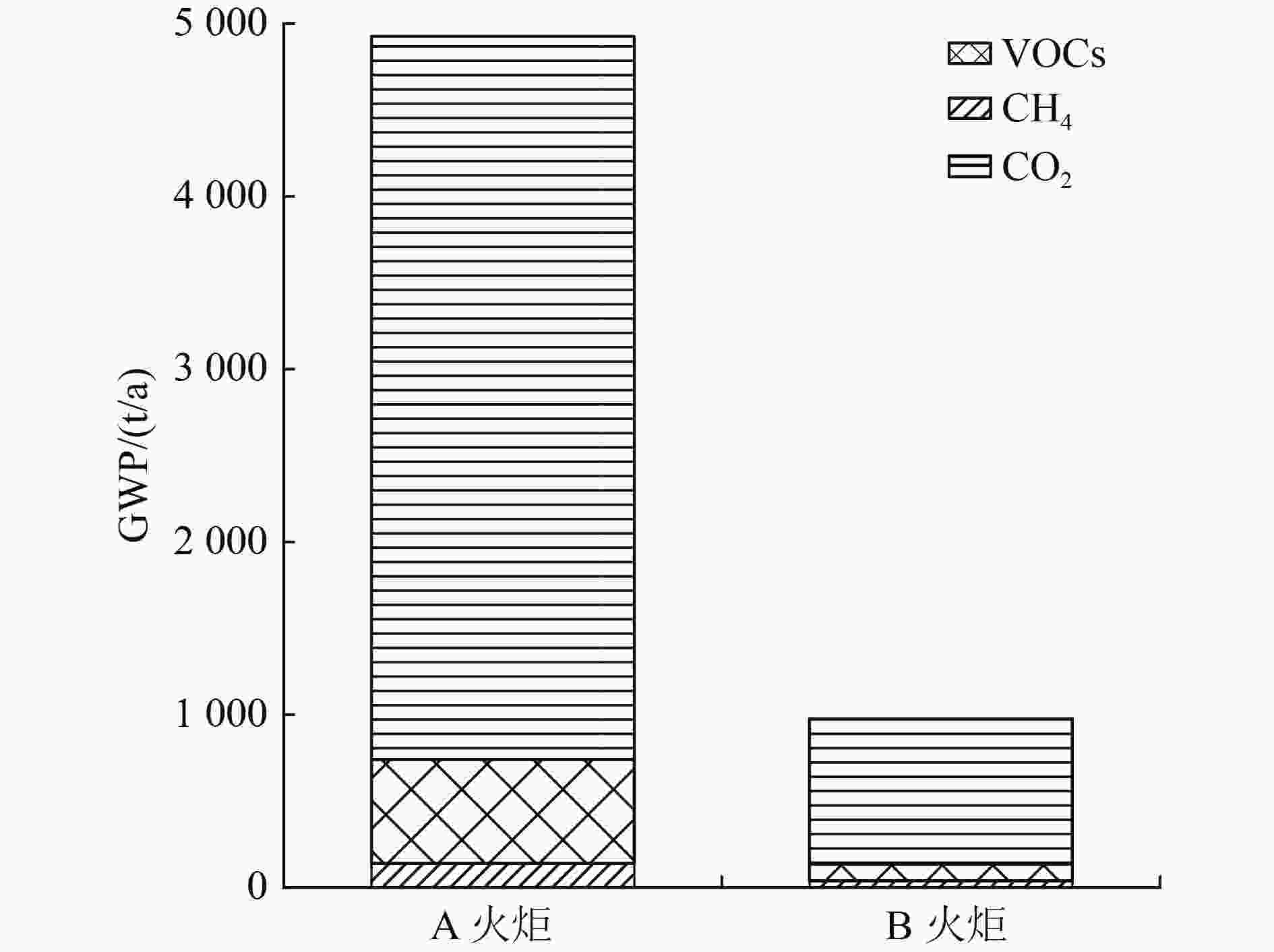

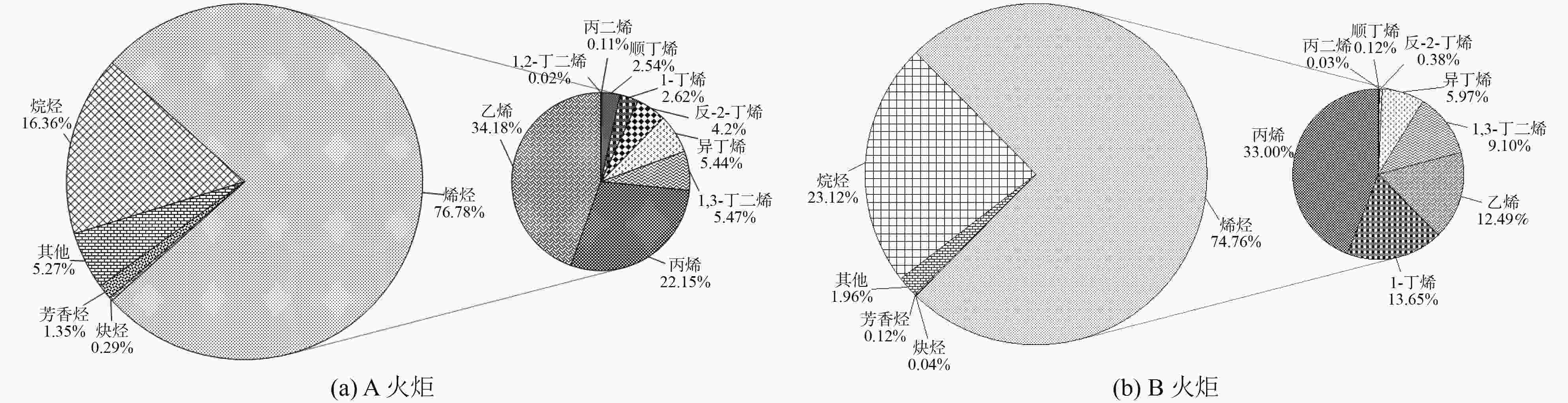

针对我国石化行业减污降碳形势严峻的现实,以具有百万吨乙烯裂解能力的某石化企业中2座地面火炬为研究对象,通过现场采样监测和模型计算,系统探讨了火炬燃烧过程中挥发性有机物(VOCs)和温室气体的排放特征。结果表明:A、B 2座火炬2021年VOCs排放量分别为310.56和77.38 t/a,烯烃是主要排放组分;温室气体排放以含碳化合物燃烧转化产生的CO2为主,排放量约占火炬CO2排放总量的99.98%;2座火炬的臭氧生成潜势(OFP)分别为3 011.72和628.97 t/a,乙烯和丙烯分别是A、B火炬OFP的主要贡献者,贡献率分别为39.52%和44.91%;2座火炬年全球增温潜势(GWP)分别为5 806.92和1 148.46 t/a(以CO2当量计),其中CO2的贡献最大,其导致的直接温室效应是CH4的25.12~35.46倍,是VOCs排放间接导致温室效应的6.64~7.24倍。

Abstract:In response to the severe situation of pollution and carbon reduction in China's petrochemical industry, two ground flares in a petrochemical company with millions of tons of ethylene cracking capacity were studied. Through on-site sampling monitoring and model calculation, the emission characteristics of volatile organic compounds (VOCs) and greenhouse gases from the flares during the combustion process were systematically explored. The results showed that VOCs emissions from Flare A and B in 2021 were 310.56 and 77.38 t/a, respectively, with olefins as the main emitted components. Greenhouse gas emissions were dominated by CO2 generated from the conversion of carbon-containing compounds into combustion, accounting for about 99.98% of the total CO2 emissions from flares. The ozone formation potential (OFP) of Flare A and B was 3 011.72 and 628.97 t/a, respectively, and ethylene and propylene were the main contributors to OFP of Flare A and B, with contribution rate of 39.52% and 44.91%, respectively. The global warming potential (GWP) of the two flares was 5 806.92 and 1 148.46 t/a CO2eq, respectively, with CO2 contributing the most, leading to a direct greenhouse effect which was 25.12-35.46 times that of CH4, and 6.64-7.24 times that of the greenhouse effect indirectly caused by VOCs emissions.

-

表 1 研究对象的基本信息

Table 1. Basic information of research objects

火炬 具体组成 最大设计流量/(t/h) 进口压力/

kPa最大允

许背压/kPaA 由烯烃装置区的火炬总管、分液罐及凝液泵、水封罐、燃烧装置组成 1 800 100 200 B 由苯乙烯装置、聚烯烃装置以及来自球罐区、燃料气系统、低温罐区、乙烯管网、丙烯码头管线、天然气计量站、氢气计量站的火炬总管、分液罐、凝液泵、水封罐、燃烧装置组成 800 100 200 表 2 火炬气组分中具有温室气体效应的VOCs物种CO2排放量转换系数

Table 2. Conversion factors for CO2 emissions of VOCs species with an indirect effect on GHGs in the flares

VOCs 分子式 α 乙烷 C2H6 5.5 乙烯 C2H4 3.7 丙烯 C3H6 1.8 丙烷 C3H8 3.3 异丁烷 C4H10 4.0 正丁烷 C4H10 4.0 甲苯 C7H8 3.7 表 3 火炬VOCs排放量贡献前10位的VOCs物种

Table 3. Top 10 VOCs species contributing to VOCs emissions from flares

t/a 排名 A火炬 B火炬 VOCs物种 2021年排放量 VOCs物种 2021年排放量 1 乙烯 106.16 丙烯 25.54 2 丙烯 68.8 1-丁烯 10.57 3 乙烷 29.26 乙烯 9.66 4 1,3-丁二烯 16.98 1,3-丁二烯 7.04 5 异丁烯 16.88 乙烷 5.97 6 C5~C8类 16.37 正戊烷 4.74 7 正丁烷 13.11 异丁烯 4.62 8 反-2-丁烯 13.05 丙烷 2.68 9 1-丁烯 8.15 正丁烷 1.92 10 顺丁烯 7.87 异戊烷 1.72 -

[1] 马超, 薛志钢, 李树文, 等. VOCs排放、污染以及控制对策[J]. 环境工程技术学报,2012,2(2):103-109.MA C, XUE Z G, LI S W, et al. VOCs emission, pollution and control measures[J]. Journal of Environmental Engineering Technology,2012,2(2):103-109. [2] ZHENG H, KONG S F, YAN Y Y, et al. Compositions, sources and health risks of ambient volatile organic compounds (VOCs) at a petrochemical industrial park along the Yangtze River[J]. Science of the Total Environment,2020,703:135505. doi: 10.1016/j.scitotenv.2019.135505 [3] 张钢锋, 卜梦雅, 李杰. 我国挥发性有机物(VOCs)研究进展与态势分析[J]. 安全与环境学报,2023,23(3):951-961.ZHANG G F, BU M Y, LI J. Research progress and trend analysis of volatile organic compounds in China[J]. Journal of Safety and Environment,2023,23(3):951-961. [4] YEN C H, HORNG J J. Volatile organic compounds (VOCs) emission characteristics and control strategies for a petrochemical industrial area in middle Taiwan[J]. Journal of Environmental Science and Health, Part A,2009,44(13):1424-1429. doi: 10.1080/10934520903217393 [5] 江梅, 张国宁, 邹兰, 等. 有机溶剂使用行业VOCs排放控制标准体系的构建[J]. 环境工程技术学报,2011,1(3):221-225.JIANG M, ZHANG G N, ZOU L, et al. Study on emission control standard system of VOCs from the use of organic solvents in industries[J]. Journal of Environmental Engineering Technology,2011,1(3):221-225. [6] 费波, 卜梦雅, 张钢锋. 典型石化装置挥发性有机物排放特征及臭氧生成潜势[J]. 环境工程,2023,41(5):172-178.FEI B, BU M Y, ZHANG G F. Research on vocs emission characteristics and ozone formation potential of typical petrochemical plants[J]. Environmental Engineering,2023,41(5):172-178. [7] RAVANCHI M T, SAHEBDELFAR S, ZANGENEH F T. Carbon dioxide sequestration in petrochemical industries with the aim of reduction in greenhouse gas emissions[J]. Frontiers of Chemical Science and Engineering,2011,5(2):173-178. doi: 10.1007/s11705-010-0562-1 [8] GAI H L, WANG A N, FANG J, et al. Clean combustion and flare minimization to reduce emissions from process industry[J]. Current Opinion in Green and Sustainable Chemistry,2020,23:38-45. doi: 10.1016/j.cogsc.2020.04.006 [9] PIKELNAYA O, FLYNN J H, TSAI C, et al. Imaging DOAS detection of primary formaldehyde and sulfur dioxide emissions from petrochemical flares[J]. Journal of Geophysical Research:Atmospheres,2013,118(15):8716-8728. doi: 10.1002/jgrd.50643 [10] 王震东, 沈晓波, 修光利, 等. 国内外石化行业火炬污染排放控制标准与规范研究[J]. 环境科学研究,2019,32(9):1456-1463.WANG Z D, SHEN X B, XIU G L, et al. Domestic and global standards and specifications for gas flare emission control in petrochemical industry[J]. Research of Environmental Sciences,2019,32(9):1456-1463. [11] ALLEN D, MURPHY C, KIMURA Y, et al. Variable industrial VOC emissions and their impact on ozone formation in the Houston Galveston area[R]. Texas: Texas Environmental Research Consortium, 2004. [12] THOMAS R, SMITH J, JONES M, et al. Emissions modeling of specific highly reactive volatile organic compounds (HRVOC) in the Houston-Galveston-Brazoria ozone nonattainment area[C]//17th annual international emission inventory conference: inventory evolution. Portland: Portal to Improved Air Quality, 2008. [13] US EPA. Greenhouse gas reporting program industrial profile: petroleum refineries sector[EB/OL]. [2023-08-15]. https://www.epa.gov/sites/default/files/2019-10/documents/petroleum_refineries_industrial_profile9252019.pdf. [14] 高元. 大型化工装置火炬系统防回火技术的研究与探讨[J]. 化工进展,2014,33(增刊1):322-325.GAO Y. Research and discussion on anti-backfire technology of flare system in large chemical plant[J]. Chemical Industry and Engineering Progress,2014,33(Suppl 1):322-325. [15] 薛超, 吴昊, 何懿伦, 等. 油田火炬管网系统设计及优化研究[J]. 油气田地面工程,2023,42(9):8-13.XUE C, WU H, HE Y L, et al. Design and optimization of oilfield flare pipe network system[J]. Oil-Gas Field Surface Engineering,2023,42(9):8-13. [16] 翟鹏, 韩玉恒. 苯抽提装置火炬管线冻堵的原因及解决措施[J]. 石油化工安全环保技术,2009,25(1):35-36.ZHAI P, HAN Y H. The causation of the benzene extraction unit torch pipeline freeze blockage and its resolution measures[J]. Petrochemical Safety and Environmental Protection Technology,2009,25(1):35-36. [17] 申元鹏, 刘剑, 杨涛. 炼油区火炬总管大检修动火施工安全管控措施[J]. 石油化工安全环保技术,2020,36(2):18-21.SHEN Y P, LIU J, YANG T. Safety control measures for hot work construction of torch main pipe overhaul in oil refining area[J]. Petrochemical Safety and Environmental Protection Technology,2020,36(2):18-21. [18] 焦厚骏. 火炬气回收装置水封阀系统应用分析[J]. 化工技术经济,2003,21(1):44-49.JIAO H J. Water seal arrangement for flare gas recovery and its improvement[J]. Chemical Techno-Economics,2003,21(1):44-49. [19] 束长好. 炼油厂火炬气回收利用的分析[J]. 化学工业与工程技术,2009,30(6):52-54. [20] 姚亚娟. 火炬气回收利用的研究进展[J]. 石油化工技术与经济,2016,32(2):58-62.YAO Y J. Research advance of recovery of flare gas recycling[J]. Techno-Economics in Petrochemicals,2016,32(2):58-62. [21] 陈国华, 黄庭枫, 梁栋. 分区域-多点源的高架火炬安全距离计算新模型[J]. 天然气工业,2013,33(12):168-172.CHEN G H, HUANG T F, LIANG D. A new safety distance calculation model of vertical jet fires based on sub-regions and multi-point sources[J]. Natural Gas Industry,2013,33(12):168-172. [22] 秦琴, 王玮, 张磊. 长输天然气管道放空火炬热辐射距离计算方法探讨[J]. 化工机械,2009,36(6):566-569.QIN Q, WANG W, ZHANG L. Discussions on the calculation methods of the thermal radiation distance of the flare stack in long distance natural gas pipelines[J]. Chemical Engineering & Machinery,2009,36(6):566-569. [23] 王栋成, 林国栋, 王静. 火炬源大气环境影响评价技术方法研究及应用[J]. 环境工程,2010,28(增刊1):322-325.WANG D C, LIN G D, WANG J. Research and application of technical method of the torch source of atmospheric environmental impact assessment[J]. Environmental Engineering,2010,28(Suppl 1):322-325. [24] 马卫东, 仝纪龙, 潘峰, 等. 石化高架火炬污染源的大气环境影响评价要点[J]. 化工环保,2013,33(3):255-258.MA W D, TONG J L, PAN F, et al. Key points in atmospheric environmental impact assessment of elevated flare pollution sources in petrochemical plants[J]. Environmental Protection of Chemical Industry,2013,33(3):255-258. [25] 郑逸璇, 宋晓晖, 周佳, 等. 减污降碳协同增效的关键路径与政策研究[J]. 中国环境管理,2021,13(5):45-51.ZHENG Y X, SONG X H, ZHOU J, et al. Synergetic control of environmental pollution and carbon emissions: pathway and policy[J]. Environmental Conformity Assessment,2021,13(5):45-51. [26] 杨儒浦, 王敏, 胡敬韬, 等. 工业园区减污降碳协同增效评价方法及实证研究[J]. 环境科学研究,2023,36(2):422-430.YANG R P, WANG M, HU J T, et al. Evaluation method and empirical study on synergistic reduction of pollution and carbon emissions in industrial parks[J]. Research of Environmental Sciences,2023,36(2):422-430. [27] 甘凤丽, 江霞, 常玉龙, 等. 石化行业碳中和技术路径探索[J]. 化工进展,2022,41(3):1364-1375.GAN F L, JIANG X, CHANG Y L, et al. Exploration of carbon neutral technology path in petrochemical industry[J]. Chemical Industry and Engineering Progress,2022,41(3):1364-1375. [28] RAHIMPOUR M R, JAMSHIDNEJAD Z, JOKAR S M, et al. A comparative study of three different methods for flare gas recovery of Asalooye Gas Refinery[J]. Journal of Natural Gas Science and Engineering,2012,4:17-28. doi: 10.1016/j.jngse.2011.10.001 [29] Office of the Federal Register, N. A. and R. A. National emission standards for hazardous air pollutants and new source performance standards: petroleum refinery sector amendments: 83 FR 15458[S/OL]. [2023-05-12]. https://www.govinfo.gov/app/details/FR-2018-04-10/2018-06223. [30] BEIGIPARAST S, TAHOUNI N, ABBASI M, et al. Flare gas reduction in an olefin plant under different start-up procedures[J]. Energy,2021,214:118927. doi: 10.1016/j.energy.2020.118927 [31] 葛安卡, 张礼敬, 张杰东, 等. 基于三元组分法的火炬气燃烧机制[J]. 南京工业大学学报(自然科学版),2019,41(1):52-56.GE A K, ZHANG L J, ZHANG J D, et al. Burning reason of flare gas based on ternary component chart[J]. Journal of Nanjing University of Technology (Natural Science Edition),2019,41(1):52-56. [32] 刘强. 石化企业火炬事故状态下大气环境污染分析[J]. 资源节约与环保,2017(7):24-25.LIU Q. Analysis of atmospheric environmental pollution under torch accident in petrochemical enterprises[J]. Resources Economization & Environmental Protection,2017(7):24-25. [33] 周粉慧. 火炬气在线监测系统选型及工程应用[J]. 化工设计通讯,2023,49(1):73-75.ZHOU F H. Selection and engineering application of online flare gas monitoring system[J]. Chemical Engineering Design Communications,2023,49(1):73-75. [34] 上海市生态环境局. 上海市石化行业VOCs排放量计算方法(试行)[S/OL]. [2023-08-15]. https://sthj.sh.gov.cn/hbzhywpt1133/hbzhywpt1135/20170308/0024-103293.html. [35] HERNDON S C, NELSON D D Jr, WOOD E C, et al. Application of the carbon balance method to flare emissions characteristics[J]. Industrial & Engineering Chemistry Research,2012,51(39):12577-12585. [36] 生态环境部. 石化行业VOCs污染源排查工作指南[S/OL]. [2023-08-15]. https://www.mee.gov.cn/gkml/hbb/bgt/201511/W020151124546327744099.pdf. [37] DENG Y Y, LI J, LI Y Q, et al. Characteristics of volatile organic compounds, NO2, and effects on ozone formation at a site with high ozone level in Chengdu[J]. Journal of Environmental Sciences,2019,75:334-345. doi: 10.1016/j.jes.2018.05.004 [38] CARTER W P L. Development of ozone reactivity scales for volatile organic compounds[J]. Air & Waste,1994,44(7):881-899. [39] 王学臣, 王帅, 刘大喜, 等. 典型工业源挥发性有机物排放特征及臭氧生成潜势分析[J]. 环境污染与防治,2020,42(11):1387-1391.WANG X C, WANG S, LIU D X, et al. VOCs emission characteristics and ozone formation potential analysis of typical industrial sources[J]. Environmental Pollution and Control,2020,42(11):1387-1391. [40] 国家发展和改革委员会. 中国石油化工企业温室气体排放核算方法与报告指南(试行)[S/OL]. [2023-08-15]. https://www.ndrc.gov.cn/xxgk/zcfb/tz/201502/W020190905507323633548.pdf. [41] 国家发展和改革委员会. 中国石油天然气生产企业温室气体排放核算方法与报告指南(试行)[S/OL]. [2023-08-15]. https://www.ndrc.gov.cn/xxgk/zcfb/tz/201502/W020190905507323097054.pdf. [42] ALLAN R P, ACHUTARAO K M. Climate change 2021: the physical science basis: Working Group Ⅰ contribution to the sixth assessment report of the Intergovernmental Panel on climate change[M].Cambridge: Cambridge University Press, 2021: 1-2391. [43] IPCC. Climate change 2021: the physical science basis[M]. Cambridge: Cambridge University Press, 2021: 4-41. [44] COLLINS W J, DERWENT R G, JOHNSON C E, et al. The oxidation of organic compounds in the troposphere and their global warming potentials[J]. Climatic Change,2002,52(4):453-479. doi: 10.1023/A:1014221225434 [45] FORSTER P, RAMASWAMY V. Chapter 2: changes in atmospheric constituents and in radiative forcing[S]. Cambridge: IPCC, 2005. [46] 吴宗进, 吴宜展. 六轻工业园区推动排燃烧塔废气回收及促进循环经济之成效检讨[J]. 环境工程会刊,2016(3):1-7. [47] ZADAKBAR O, VATANI A, KARIMPOUR K. Flare gas recovery in oil and gas refineries[J]. Oil & Gas Science and Technology,2008,63(6):705-711. [48] FISHER P W, BRENNAN D. Minimize flaring with flare gas recovery[J]. Hydrocarbon Processing,2002,81(6):83-85. □ -

下载:

下载: