Evaluation method of synergistic benefits enhancement technologies for pollution abatement and carbon reduction in the ironmaking process

-

摘要:

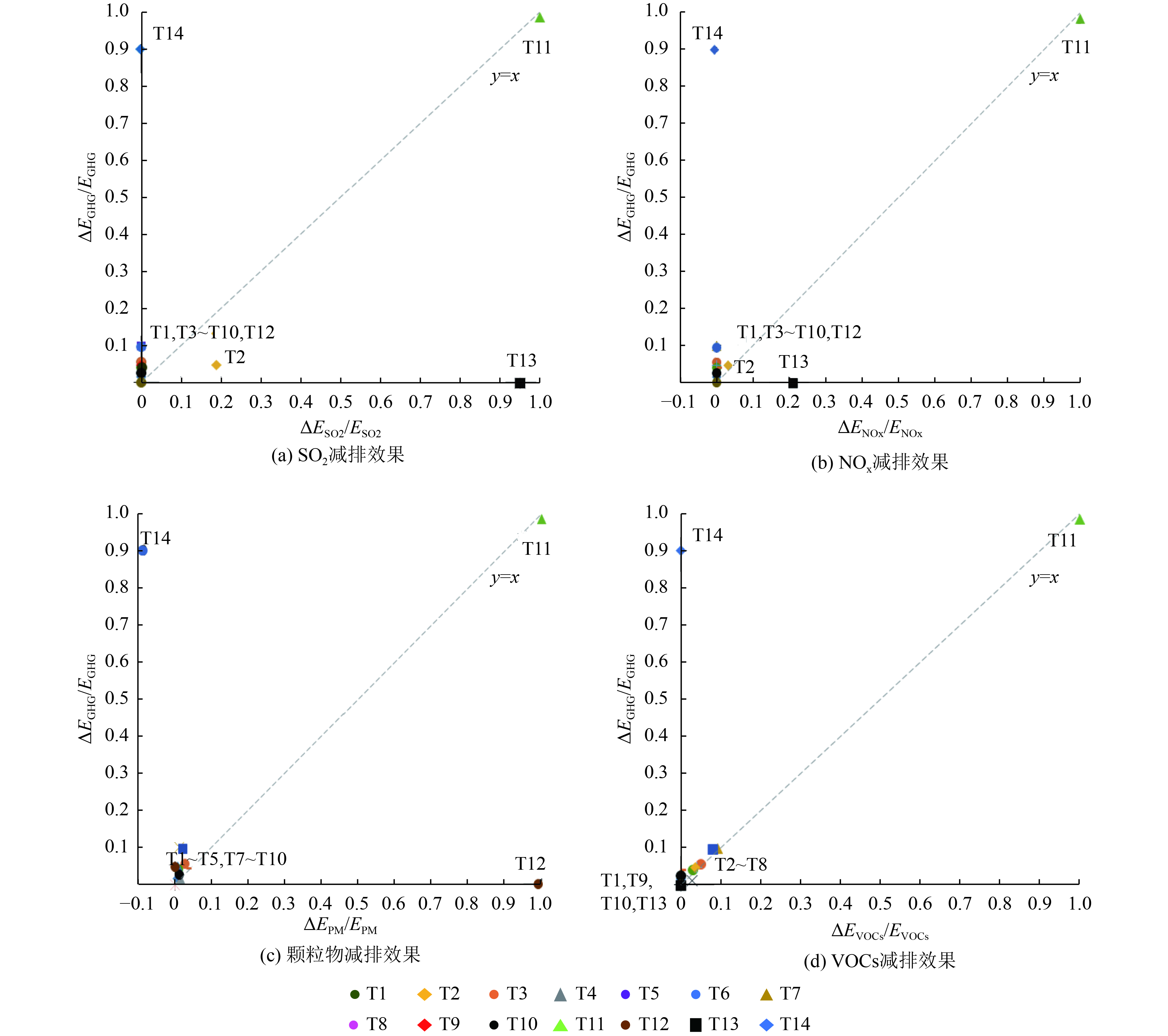

为推广减污降碳协同控制技术,以炼铁工序为研究对象,从协同度、成本收益和环境影响3个维度评价炼铁工序源头、过程节能技术、末端治理技术和低碳技术的协同控制效益。从污染物和碳排放协同度分析来看,源头、过程节能技术能有效推动炼铁工序污染物和碳排放的协同减排,而末端控制技术对污染物和温室气体的减排不具有协同性。绿氢冶炼技术和熔剂性球团制备技术污碳减排协同度较高,此外高炉喷吹焦炉煤气技术、高炉煤气回收技术和高炉热风炉双预热能协同减少VOCs和碳排放。在当前我国碳交易价格条件下,从成本收益分析来看节能技术和污染物末端治理技术具有可推广性。随着碳交易价格的上涨,绿氢冶炼和碳捕集(CCS)技术减排成本呈下降趋势。绿氢冶炼技术、污染物末端治理技术最能有效地减少环境影响,其他节能技术也能相应减少环境影响,而现有条件下CCS技术的实施会增加对环境的影响。综合污染物和温室气体协同减排的协同度、经济效益和环境效益评估,炼铁工序中源头防治和节能技术可作为我国现阶段减污降碳协同增效技术进行推广,随着未来碳交易价格的增长和能源的转型,绿氢冶炼技术和CCS技术具有较大应用前景。

Abstract:To promote the synergetic reduction technologies of pollution and carbon, the ironmaking process technology was taken as the research object, and the synergistic benefits of source and process-control technologies, end treatment technologies, and low-carbon technologies were evaluated from three perspectives of synergy level, cost-benefit, and environmental impact. In terms of synergy between pollution abatement and carbon reduction, the source and process-control energy-saving technologies could effectively promote the synergistic reduction of pollutants and carbon emissions of the ironmaking process, while end treatment technologies could not synergistically reduce pollutants and carbon emissions. Specifically, the green hydrogen smelting technology and flux-based pellet preparation technology had a high degree of synergy in reducing pollution and carbon emissions. The injection coke oven gas technology, blast-furnace gas recovery technology, and dual preheating of the hot blast furnace could synergistically reduce VOCs and carbon emissions. Under China's current carbon trading prices, energy-saving technologies and pollutant treatment technologies could be popularized according to the cost-benefit analysis. The cost of green hydrogen smelting and CCS technologies was declining with the rise of carbon trading prices. Green hydrogen smelting and pollutant treatment technologies were the most effective ways to reduce environmental impact, while other energy-saving technologies could also correspondingly reduce environmental impact. Under existing conditions, the implementation of CCS technologies would increase environmental impact. Based on the assessment of synergy between pollution abatement and carbon reduction, economic benefits and environmental benefits, the source prevention and energy-saving technologies in the ironmaking process could be promoted as China's current pollution reduction and carbon reduction synergy technologies. With the increase in carbon emission trading prices and green transformation in the future, green hydrogen smelting and CCS technologies would have great application prospects.

-

表 1 钢铁行业炼铁工序减排技术-经济参数

Table 1. Technological and economic parameters for emission reduction technologies in ironmaking process

技术类型 编号 技术名称 燃料-煤炭节约

量/(kg/t,以标煤计)电力节约

量/(kW·h/t)原料-焦炭节约

量/(kg/t)投资成本/

(元/t)运行成本/

(元/t)寿命/a 源头防治技术 T1 高炉鼓风除湿技术 8.73 0 25[27] 46.81[28] 4.77[29] 20[29] T2 熔剂性球团制备技术 11[29] 89.43 18 494.11[30] 0[29] 30[29] 过程控制技术 T3 高炉炉顶煤气干式余压发电技术(TRT) 0 54 0 20.06[29] 4.16[29] 15[29] T4 高炉喷煤技术 8.91 0 14 51.85[29] 4.55[29] 20[29] T5 高炉喷吹焦炉煤气技术 10.93 13.89 45.7[31] 35.50 0 20 T6 高炉煤气回收技术 19.12 0 40[32] 3.02 0 15 T7 高炉热风炉双预热 9.7 0 15[33] 5.21 0 20 T8 旋切式高风温顶燃热风炉节能 8.07 0 20[34] 56.15 0 15 T9 高炉富氧 30.82 0 0 2434[35] 9.3[29] 20[29] T10 高炉煤气燃气-蒸汽联合循环发电(CCPP) 0 88 0 32.1[29] 0[29] 25[29] T11 绿氢冶炼技术 0 −3480 0 4350[36] 24.75[29] 20[29] 减排技术 T12 高炉煤气干式除尘 0 −0.45 0 0.93 2.52 20 T13 石灰石-石膏湿法烟气脱硫技术 0 −6.8 0 25.14[37] 10.92[29] 30[29] T14 碳捕集技术(CCS) 0 −665.77 0 196.42[38] 23.44[29] 20[29] 表 2 减污降碳协同效应系数对应的协同状态

Table 2. Synergistic state corresponding to synergistic effect coefficient of pollution abatement and carbon reduction

协同状态 $ \Delta {\mathit{E}}_{\mathbf{L}\mathbf{A}\mathbf{P}} $ $ \Delta {\mathit{E}}_{\mathbf{G}\mathbf{H}\mathbf{G}} $ S 特征 协同减排 > 0 > 0 [0, 0.8) 污染物和碳均减排,污染物减排速度低于碳减排速度 > 0 > 0 [0.8, 1.2] 污染物和碳均减排且减排速度相当 > 0 > 0 (1.2,+∞) 污染物和碳均减排,污染物减排速度高于碳减排速度 协同增排 < 0 < 0 [0, 0.8) 污染物和碳均增排,污染物增排速度低于碳减排速度 < 0 < 0 [0.8, 1.2] 污染物和碳均增排且增排速度相当 < 0 < 0 (1.2,+∞) 污染物和碳均增排,污染物增排速度高于碳减排速度 不协同 > 0 < 0 (−∞,0) 污染物减排,碳增排 < 0 > 0 (−∞,0) 污染物增排,碳减排 表 3 污染物、CO2和能源对各环境影响类别的损害因子

Table 3. Damage factors of pollutants, greenhouse gases, and energy on various environmental impact categories

终点伤害类别 环境影响类别 项目 损害因子(空气中) 人均基础值[35] 人体健康 致癌作用[46] As 2.37×10−3 d/kg 0.019 d Cd 4.89×10−4 d/kg Cr 7.58×10−2 d/kg Ni 1.22×10−3 d/kg 气候变化[47] CO2当量 9.28×10−7 d/kg 细颗粒物形成[48] SO2 1.82×10−4 d/kg PM 6.29×10−4 d/kg NOx 6.92×10−5 d/kg 光化学臭氧形成[35] NOx 9.10×10−7 d/kg VOCs 1.64×10−7 d/kg 生态系统 生态毒性[36] As 8.94×10−7 species/kg 6.08×10−5 species Cd 2.69×10−6 species /kg Cr 1.35×10−9 species /kg Ni 1.29×10−6 species/kg 气候变化[37] CO2当量 2.80×10−9 species/kg 酸化[49] SO2 2.12×10−7 species/kg NOx 7.63×10−8 species/kg 光化学臭氧形成[35] NOx 1.29×10−7 species/kg VOCs 3.74×10−8 species/kg 资源 化石燃料[50] 煤炭 2.50×10−1 MJ/kg 2 467.42 MJ 表 4 技术减污降碳协同度

Table 4. Synergistic degree of pollution abatement and carbon reduction

技术 $S_{{\mathrm{SO}}_2} $ $S_{{\mathrm{NO}}_x} $ S颗粒物 SVOCs T1 1.36×10−2 2.68×10−2 4.73×10−1 0 T2 4.12 7.01×10−1 0 7.83×10−1 T3 1.39×10−2 2.51×10−2 4.83×10−1 9.08×10−1 T4 3.65×10−2 6.59×10−2 1.27 2.38 T5 3.50×10−3 6.30×10−3 1.22×10−1 9.32×10−1 T6 6.40×10−3 1.15×10−2 2.20×10−1 8.41×10−1 T7 7.90×10−3 1.40×10−2 2.72×10−1 7.69×10−1 T8 5.60×10−3 1.01×10−2 1.94×10−1 8.78×10−1 T9 2.39×10−2 4.92×10−2 8.29×10−1 0 T10 1.36×10−2 2.46×10−2 4.73×10−1 0 T11 1.02 1.02 1.02 1.02 T12 1.36×10−2 2.46×10−2 −7.95×103 0 T13 −5.05×102 −1.12×102 0 0 T14 −2.90×10−3 −5.20×10−3 −9.96×10−2 0 表 5 技术的环境影响核算结果

Table 5. Environmental impact of the technologies

技术 人体健康影响

减少量生态系统影响

减少量资源消耗

减少量环境影响

减少总量T1 3.33×10−2 5.54×10−3 9.11×10−4 2.15×10−2 T2 4.18×10−2 1.08×10−2 1.11×10−3 2.80×10−2 T3 1.35×10−2 1.57×10−3 6.73×10−4 8.58×10−3 T4 2.30×10−2 1.32×10−3 9.29×10−4 1.43×10−2 T5 4.35×10−2 9.69×10−3 1.14×10−3 2.87×10−2 T6 5.67×10−2 9.56×10−3 1.99×10−3 3.67×10−2 T7 2.63×10−2 3.96×10−3 1.01×10−3 1.69×10−2 T8 2.54×10−2 4.56×10−3 8.42×10−4 1.65×10−2 T9 6.12×10−2 4.52×10−3 3.21×10−3 3.84×10−2 T10 2.20×10−2 2.55×10−3 1.10×10−3 1.40×10−2 T11 6.03×10−2 1.50×10−1 −4.34×10−2 6.71×10−2 T12 6.71×10−2 −1.31×10−5 −5.61×10−6 4.03×10−2 T13 7.59×10−2 3.22×10−2 −8.47×10−5 5.36×10−2 T14 −1.03×10−1 4.45×10−2 −8.54×10−3 −5.18×10−2 表 6 不同贴现率下技术污碳减排成本

Table 6. Cost of the technologies synergetic reduction of pollution and carbon reduction under different discount rates

技术 减排成本/(元/t) 贴现率为5% 贴现率为10% 贴现率为15% T1 −23.76 −22.01 −20.03 T2 −16.07 4.21 27.04 T3 −54.47 −53.76 −52.97 T4 −51.45 −49.52 −47.33 T5 −53.87 −52.55 −51.05 T6 −64.19 −64.09 −63.97 T7 −31.03 −30.84 −30.62 T8 −22.55 −20.58 −18.36 T9 116.00 206.60 309.60 T10 −89.63 −88.37 −86.94 T11 3 505.00 3 667.00 3 851.00 T12 −9.12 −9.08 −9.04 T13 −53.72 −52.69 −51.53 T14 644.50 651.80 660.20 -

[1] CHENG J, TONG D, ZHANG Q, et al. Pathways of China's PM2.5 air quality 2015-2060 in the context of carbon neutrality[J]. National Science Review, 2021, 8(12): 78. [2] QIAN H Q, XU S D, CAO J, et al. Air pollution reduction and climate co-benefits in China's industries[J]. Nature Sustainability,2021,4(5):417-425. doi: 10.1038/s41893-020-00669-0 [3] SCHEFFE R, HUBBELL B, FOX T et al, The rationale for a multipollutant-multimedia air quality management framework[J]. Air & Waste Management Association, 2007, 5: 14 -20. [4] 姜华, 李艳萍, 高健. 双碳背景下煤基产业绿色低碳转型之路[J]. 环境工程技术学报,2022,12(5):1580-1583.JIANG H, LI Y P, GAO J. The road of green and low-carbon transformation of coal-based industry under carbon peak and carbon neutrality background[J]. Journal of Environmental Engineering Technology,2022,12(5):1580-1583. [5] 张剑, 刘景洋, 董莉, 等. 中国能源消费CO2排放的影响因素及情景分析[J]. 环境工程技术学报,2023,13(1):71-78. doi: 10.12153/j.issn.1674-991X.20210563ZHANG J, LIU J Y, DONG L, et al. Influencing factors and scenario analysis of China's CO2 emission of energy consumption[J]. Journal of Environmental Engineering Technology,2023,13(1):71-78. doi: 10.12153/j.issn.1674-991X.20210563 [6] 顾斌杰, 赵海霞, 骆新燎, 等, 基于文献计量的减污降碳协同减排研究进展与展望[J]. 环境工程技术学报, 2023, 13(1): 85-95.GU B J, ZHAO H X, LUO X L, et al. Research progress and prospect of collaborative reduction of pollution and carbon dioxide based on bibliometrics[J]. Journal of Environmental Engineering Technology, 2023, 13(1): 85-95. [7] ZHU J P, WU S H, XU J B. Synergy between pollution control and carbon reduction: China's evidence[J]. Energy Economics,2023,119:106541. doi: 10.1016/j.eneco.2023.106541 [8] IPPC Directive. BAT reference documents[EB/OL]. [2023-09-01]. http://eippcb.jrc.es/reference/. [9] The Low Carbon Innovation Co-ordination Group. LCICG strategic framework[EB/OL]. [2023-09-01]. https://www.gov.uk/guidance/ energy-innovation-evidence-the-low-carbon-innovation-co-ordination-group. [10] 生态环境部. 国家重点推广的低碳技术目录[EB/OL]. [2023-09-01]. https://www.mee.gov.cn/ywgz/ydqhbh/wsqtkz/201904/t20190419_700385.shtml. [11] 国家发展和改革委员会. 国家重点节能技术推广目录[EB/OL]. [2023-09-01]. https://www.ndrc.gov.cn/xxgk/zcfb/gg/201001/ t20100111_961442.html?code=&state=123. [12] 中央人民政府. 关于印发《绿色技术推广目录(2020年)》的通知[EB/OL]. [2023-09-01]. http://www.gov.cn/zhengce/zhengceku/2021-01/08/content_5578253.htm. [13] 生态环境部. 国家环境技术管理体系建设规划[EB/OL]. [2023-09-01]. https://www.mee.gov.cn/gkml/zj/wj/200910/W020071011272194709927.pdf. [14] 生态环境部. 关于印发2021年《国家先进污染防治技术目录》的通知[EB/OL]. [2023-09-01]. https://www.mee.gov.cn/xxgk2018/xxgk/xxgk06/202112/ t20211224_ 965183html. [15] RYPDAL K, RIVE N, ASTRÖM, et al. Nordic air quality co-benefits from European post-2012 climate policies[J]. Energy Policy,2007,35(12):6309-6322. doi: 10.1016/j.enpol.2007.07.022 [16] 王涵, 李慧, 王涵, 等. 我国减污降碳与地区经济发展水平差异研究[J]. 环境工程技术学报,2022,12(5):1584-1592. doi: 10.12153/j.issn.1674-991X.20210268WANG H, LI H, WANG H, et al. Research on the difference in air pollution and carbon dioxide reduction and regional economic development levels in China[J]. Journal of Environmental Engineering Technology,2022,12(5):1584-1592. doi: 10.12153/j.issn.1674-991X.20210268 [17] 杨儒浦, 王敏, 胡敬韬, 等. 工业园区减污降碳协同增效评价方法及实证研究[J]. 环境科学研究,2023,36(2):422-430.YANG R P, WANG M, HU J T, et al. Evaluation method and empirical study on synergistic reduction of pollution and carbon emissions in industrial parks[J]. Research of Environmental Sciences,2023,36(2):422-430. [18] 毛显强, 曾桉, 胡涛, 等. 技术减排措施协同控制效应评价研究[J]. 中国人口·资源与环境, 2011, 21(12): 1-6.MAO X Q, ZENG A, HU T, et al. Study of coordinate control effect assessment of technological measures for emissions reduction[J], Chinese Population Resources and Environment, 2011, 21(12): 1-7. [19] MAO X Q, ZENG A, HU T, et al, Co-control of local air pollutants and CO2 in the Chinese iron and steel industry[J]. Environmental Science & Technology, 2013, 47(21): 12002-12010. [20] 唐伟, 郑思伟, 何平, 等. 基于情景分析的杭州市机动车尾气排放控制协同效应研究[J]. 环境科学学报,2019,39(6):2033-2042. doi: 10.13671/j.hjkxxb.2019.0097TANG W, ZHENG S W, HE P, et al. Study on the co-benefit of motor vehicle emission control based on scenario analysis in Hangzhou[J]. Acta Scientiae Circumstantiae,2019,39(6):2033-2042. doi: 10.13671/j.hjkxxb.2019.0097 [21] MA D, CHEN W, YIN X, et al. Quantifying the co-benefits of decarbonisation in China's steel sector: an integrated assessment approach[J]. Applied Energy,2016,162:1225-1237. doi: 10.1016/j.apenergy.2015.08.005 [22] 工业和信息化部, 钢铁行业节能减排先进适用技术目录[EB/OL]. [2023-10-01]. http://www.miit.gov.cn/n1146285/n1146352/n3054355/n3057542/n3057545/c3650311/content.html, 2012-09-01/2017-06-01. [23] 国家发展和改革委员会. 国家重点节能低碳技术推广目录(第一批)[EB/OL]. [2023-10-01]. https://www.gov.cn/xinwen/2017-04/01/5182743/files/2bd3969838834328971fdb44a44f698d.pdf. [24] 国家发展和改革委员会. 国家重点节能低碳技术推广目录(第四批)[EB/OL]. [2023-09-01]. https://www.mee.gov.cn/xxgk2018/xxgk/xxgk06/202212/t20221221_1008424.html. [25] 任明. 京津冀地区钢铁行业能源、大气污染物和水协同控制研究[D]. 北京: 中国矿业大学(北京), 2019: 76-79. [26] IEA. Iron and steel technology roadmap: towards more sustainable steelmaking[EB/OL]. [2023-09-01]. https://doi.org/10.1787/3dcc2a1b-en. [27] 王思鹏. 高炉脱湿鼓风技术及其在新钢应用的可行性探讨[J]. 江西冶金,2017,37(6):44-47.WANG S P. BF Dehumidified blasting technology and its feasibility in Xinyu Steel[J]. Jiangxi Metallurgy,2017,37(6):44-47. [28] WU X C, ZHAO L, ZHANG Y X, et al. Cost and potential of energy conservation and collaborative pollutant reduction in the iron and steel industry in China[J]. Applied Energy,2016,184:171-183. doi: 10.1016/j.apenergy.2016.09.094 [29] 王新东, 李建新, 胡启晨. 基于高炉炉料结构优化的源头减排技术及应用[J]. 钢铁, 2019, 54(12): 104-110.WANG X D, LI J X, HU Q C. Application practice of source and process sulfur-nitrate reduction technology based on optimization of blast furnace charge structure[J]. Iron & Steel, 2019, 54(12): 104-110. [30] 许贵宾. 熔剂性球团矿的生产实践[C]//2014年全国炼铁生产技术会暨炼铁学术年会文集(上). 北京:中国金属学会, 2014:473-478. [31] 王鹤涛, 赵超, 易轰. 钢铁行业专题研究报告: 中国钢企低碳之路[EB/OL]. [2023-09-01]. 武汉: 长江证券. https://k.sina.com.cn/article_7426890874. [32] 周东东, 程树森, 程子建, 等. 高炉煤气利用率对焦比的影响研究[C]//全国大高炉炼铁学术年会. 北京: 中国金属学会, 2013: 456-461. [33] 董洪旺. 高炉冶炼炼铁技术工艺及应用分析[J]. 中国金属通报,2020(5):6. doi: 10.3969/j.issn.1672-1667.2020.05.004DONG H W. Analysis on the technology and application of blast furnace smelting and ironmaking[J]. China Metal Bulletin,2020(5):6. doi: 10.3969/j.issn.1672-1667.2020.05.004 [34] 姜凤山. 旋切式顶燃热风炉技术特点[J]. 炼铁,2010,29(4):11-14. doi: 10.3969/j.issn.1001-1471.2010.04.003JIANG F S. Technical features of cyclone type top combustion hot stove[J]. Ironmaking,2010,29(4):11-14. doi: 10.3969/j.issn.1001-1471.2010.04.003 [35] 杨见博. 钢铁企业氧气系统决策分析与优化模型研究[D]. 沈阳: 东北大学, 2012: 50-65. [36] VOGL V, ÅHMAN M, NILSSON L J. Assessment of hydrogen direct reduction for fossil-free steelmaking[J]. Journal of Cleaner Production,2018,203:736-745. doi: 10.1016/j.jclepro.2018.08.279 [37] 王志轩, 彭俊, 张家杰等. 石灰石-石膏法烟气脱硫费用分析[J]. 中国电力,2004,37(2):69-72.WANG Z X, PENG J, ZHANG J J, et al. Cost analysis of limestone-gypsum method flue gas desulfurization[J]. Electric Power,2004,37(2):69-72. [38] 王尧. 基于钢铁厂碳捕集的CCUS-EOR全流程项目技术经济评价研究[D]. 北京: 华北电力大学, 2018: 37-56. [39] 王凤婷, 方恺, 于畅. 京津冀产业能源碳排放与经济增长脱钩弹性及驱动因素: 基于Tapio 脱钩和LMDI 模型的实证[J]. 工业技术经济,2019,38(8):32-40.WANG F T, FANG K, YU C. Decoupling between industrial energy-related carbon emissions and economic growth and its driving factors in Beijing, Tianjin and Hebei urban agglomeration: empirical study based on tapio decoupling and LMDI model[J]. Journal of Industrial Technological Economics,2019,38(8):32-40. [40] 刘茂辉, 岳亚云, 刘胜楠, 等. 基于STIRPAT模型天津减污降碳协同效应多维度分析[J]. 环境科学,2023,44(3):1277-1286.LIU M H, YUE Y Y, LIU S N, et al. Multi-dimensional analysis of the synergisetic effect of pollution reduction and carbon reduction in Tianjin based on the STIRPAT Model[J]. Environmental Science,2023,44(3):1277-1286. [41] 张月. 我国钢铁工业能耗与大气污染物排放量[J]. 基层建设,2018,25:33. [42] 中国节能协会冶金工业节能专业委员会. 中国钢铁工业节能低碳发展报告(2020)[R/OL]. [2022-09-01]. https://zhuanlan.zhihu.com/p/449522831. [43] 李雪迎, 白璐, 杨庆榜, 等. 我国终点型生命周期影响评价模型及基准值初步研究[J]. 环境科学研究,2021,34(11):2778-2786. doi: 10.13198/j.issn.1001-6929.2021.08.05LI X Y, BAI L, YANG Q B, et al. Preliminary study on endpoint life cycle impact assessment model and normalisation value in China[J]. Research of Environmental Sciences,2021,34(11):2778-2786. doi: 10.13198/j.issn.1001-6929.2021.08.05 [44] GOEDKOOP M, SPRIENSMA R. The eco-indicator 99: a damage oriented method for life cycle impact assessment: methodology report[R]. Netherlands: Pré Consultants, 2001. [45] HUIJBREGTS M A J, STEINMANN Z J N, ELSHOUT P M F, et al. ReCiPe 2016: a harmonised life cycle impact assessment method at midpoint and endpoint level[J]. The International Journal of Life Cycle Assessment,2017,22(2):138-147. doi: 10.1007/s11367-016-1246-y [46] van ZELM R, HUIJBREGTS M A J, van de MEENT D. USESLCA 2.0: a global nested multi-media fate, exposure and effects model[J]. The International Journal of Life Cycle Assessment,2009,14(3):282-284. doi: 10.1007/s11367-009-0066-8 [47] JOOS F, ROTH R, FUGLESTVEDT J S, et al. Carbon dioxide and climate impulse response functions for the computation of greenhouse gas metrics: a multi-model analysis[J]. Atmospheric Chemistry and Physics,2013,13(5):2793-2825. doi: 10.5194/acp-13-2793-2013 [48] van ZELM R, PREISS P, van GOETHEM T, et al. Regionalized life cycle impact assessment of air pollution on the global scale: damage to human health and vegetation[J]. Atmospheric Environment,2016,134:129-137. doi: 10.1016/j.atmosenv.2016.03.044 [49] ROY P O, AZEVEDO L B, MARGNI M, et al. Characterization factors for terrestrial acidification at the global scale: a systematic analysis of spatial variability and uncertainty[J]. Science of the Total Environment,2014,500/501:270-276. doi: 10.1016/j.scitotenv.2014.08.099 [50] MULLER-WENK R. Depletion of abiotic resources weighted on the base of 'virtual' impacts of lower grade deposits in future[M]. Switzerland: IWO Diskussionsbeitrag Nr. 57, 1998. [51] 朱迎新, 李鹏飞, 朱晓华. 高炉生产过程中硫的来源、迁移转化及影响[C]//中国环境科学学会年会: 环境工程技术创新与应用分会场论文集(四). 北京: 中国环境科学学会, 2022: 398-403. [52] TSAI J H, LIN K H, CHEN C Y, et al. Volatile organic compound constituents from an integrated iron and steel facility[J]. Journal of Hazardous Materials,2008,157(2/3):569-578. [53] 万良丽, 宁党政. 浅谈降低焦比的理论与实践[J]. 江苏冶金科技情报,1975(2):29-34. [54] 谢明辉, 阮久莉, 白璐, 等. 太阳能级多晶硅生命周期环境影响评价[J]. 环境科学研究,2015,28(2):291-296. doi: 10.13198/j.issn.1001-6929.2015.02.17XIE M H, RUAN J L, BAO L, et al. Life cycle environmental impact assessment of solar-grade polysilico[J]. Research of Environmental Sciences,2015,28(2):291-296. doi: 10.13198/j.issn.1001-6929.2015.02.17 [55] PRÜSS-ÜSTÜN A, CORVALAN C. Preventing disease through healthy environments towards an estimate of the environmental burden of disease[EB/OL]. [2023-09-01]. Switzerland: World Health Organization. https://www.who.int/publications/i/item/9241593822. ⊕ -

下载:

下载: