Research progress of slurry bioreactor bioremediation of refractory organic matter contaminated soil

-

摘要:

生物泥浆反应器因其传质快、条件可控、修复效率高而在生物修复难降解有机物污染物土壤中得到广泛应用。综述了生物泥浆反应器生物修复土壤中难降解有机物所涉及的固液传质、气液传质和生物降解等主要去除机制,总结了3种去除机制的重要性;概括了国内外对生物反应器建模的研究进展,凝练了固液传质、气液传质和生物降解过程的基础模型;确定了生物泥浆反应器的重要参数,包括物理参数、生物参数和操作参数,并概括了各种参数的影响机理及其适宜范围。最后展望了生物泥浆反应器去除难降解有机物未来的研究方向,包括机制研究、微生物菌剂以及应用装备的智能化等。

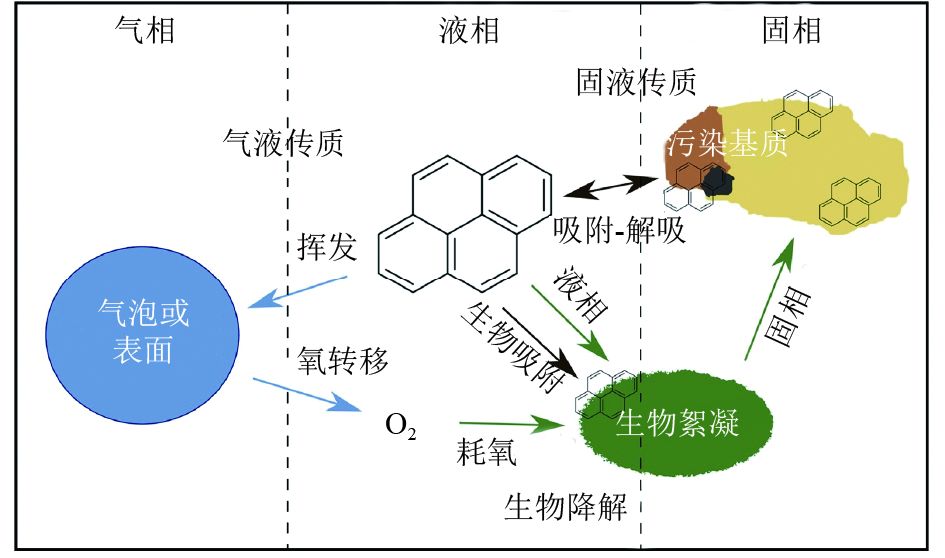

Abstract:Slurry bioreactors are widely used in bioremediation of soils polluted by refractory organic matter because of their fast mass transfer, controllable conditions and high remediation efficiency. The main removal mechanisms of solid-liquid mass transfer, gas-liquid mass transfer and biodegradation involved in the bioremediation of refractory organic matter in slurry bioreactor were reviewed, and the importance of three removal mechanisms, namely solid-liquid mass transfer, gas-liquid mass transfer and biodegradation, was summarized. The research progress of bioreactor modeling at home and abroad was summarized, and the basic models of solid-liquid mass transfer, gas-liquid mass transfer and biodegradation processes were formed. The important parameters of the slurry bioreactor were determined, including physical parameters, biological parameters and operating parameters, and the influence mechanism of various parameters and their suitable range were summarized. Finally, the future research directions of slurry bioreactor to remove refractory organic matter were prospected, including mechanism research, microbial agents, and intelligent application equipment.

-

图 1 生物泥浆反应器处理污染土壤中难降解有机物去除机制的简化模型[6]

Figure 1. A simplified model of the removal mechanism of refractory organic matter in contaminated soil treated by slurry bioreactor

图 2 土壤不同组分与土壤中吸附的难降解有机物之间的相互作用[6]

Figure 2. Interaction between different soil components and the adsorption mechanism of refractory organic matter in soil

图 3 双膜理论解释的氧转移和挥发过程[32]

注:$C_{{\rm{O}}_2} $为O2总浓度;$C_{{\rm{G, O}}_2} $为气相中O2浓度;$C^*_{{\rm{O}}_2}$为气液界面处的平衡O2浓度;$C_{{\rm{L,O}}_2}$为液相中O2浓度;CPAHs为PAHs总浓度;CL,PAHs为液相中的PAHs浓度;$C^*_{{\rm{L,PAHs}}} $为液膜处平衡PAHs浓度;$ C^*_{{\rm{G,PAHs}}} $为气膜处平衡PAHs浓度;CG,PAHs为气相中的PAHs浓度。

Figure 3. Oxygen transfer and volatilization processes explained by double membrane theory

图 4 反应系统中涉及的主要过程 [41]

Figure 4. Main processes involved in the reaction system

表 1 生物泥浆反应器主要参数、影响机理及其适宜范围[6,44]

Table 1. Main parameters, influence mechanism and suitable range of biological slurry reactor

参数 对去除效果的影响 适宜范围 物理和生物

参数温度 通过影响微生物和降解酶活性,以及有机物的生物有效性,直接影响污染物的挥发、解吸率和生物降解率:低温下微生物活性、降解酶活性受到抑制,有机物降解率下降;高温下,微生物活性降低,降解酶结构受到破坏,导致降解率偏低 20~30 ℃ pH 不仅影响微生物活性、降解酶活性、污染物结构和代谢中间产物的稳定性,还会影响反应体系中的离子强度和电子传递 5.7~8.4 土壤中污染物浓度 浓度较高时,溶解氧和底物的传质作用受到影响,降解菌与污染物不能充分接触,限制了污染物的降解速率;浓度较低时,可降低污染物对微生物的毒性,但是会导致细菌生长率低,同时用水量过大也会导致处理成本升高。因而处理过程中,应从传质作用、微生物耐受性、经济成本等方面综合考虑适宜的污染物浓度 取决于污染物种类 溶解氧(DO) 加入的氧气对土壤中的烃类污染物有直接氧化作用,促进土壤中具有降解作用的微生物进行繁殖,并且提供微生物降解过程需要的电子受体 2 mg/L至饱和 生物质浓度 控制生物降解速率和对有机物的降解率;控制有机物的生物降解过程;影响对流变学和反应器中的流体动力学 104~109 CFU/mL 污染土壤成分 黏土含量高会降低氧传递并改变流变性质;有机物含量高与污染物解吸速度慢有关 自然条件 污染物特性 污染物特性包括其生物可降解性、生物有效性和降解代谢方式等,污染物分子结构和自身的理化性质是关键因素。比如随着环数的增加,多环芳烃的疏水性增加、挥发性减小。低环多环芳烃(<3环)容易被降解,高环多环芳烃(>4环)水溶性更低,与土壤黏粒和有机质的吸附更牢固,生物可利用性偏低 微生物菌剂 土著菌的降解能力较弱,通常会加入具有较强降解能力的复合菌群,以提高污染物降解率,保证污染物彻底矿化 操作参数 混合(搅拌

速度)改善系统的均匀性和非曝气系统的充氧性。高混合速度导致较高的解吸速率,但也导致气泡聚结(和较低的氧转移速率);搅拌速度低可能导致均匀性差 20~500 r/min(取决于反应器体积) 曝气(表观气体速度) 控制溶解氧浓度和提高摄氧率。过高的曝气速度会导致气泡聚结、污染物挥发增加和生物降解率降低 10−4~10−1 m/s 土壤含量 控制反应器中污染物的浓度(底物装载)。高土壤含量可改变流变性质并影响氧转移 4%~50%(w/v) 底物装载率(SLR)、水力停留时间(HRT)和污泥停留时间(SRT) 参数调节以优化SBR和连续运行模式 SLR为10−1~104 mg/(kg·d);HRT=SRT,

为1~70 d表面活性剂

浓度对污染物溶解度和生物有效性产生影响;对微生物可能有毒性作用;对氧转移有负面影响 取决于表面活性剂的浓度 营养物浓度 影响细菌的生长,并可能提高生物降解速率 取决于微生物的需求和系统的供应 生物强化剂量 提高污染物的生物降解速率和降解率 取决于微生物的类型及其生物降解能力 -

[1] 全国土壤污染状况调查公报[EB/OL]. [2014-04-17]. http://www.gov.cn/xinwen/2014-04/17/content_2661765.htm. [2] 夏超波.土壤污染现状调查与环境保护[J]. 皮革制作与环保科技,2022(21):29-31. doi: 10.20025/j.cnki.CN10-1679.2022-21-10XIA C B. Soil pollution investigation and environmental protection[J]. Leather Manufacture and Environmental Technology,2022(21):29-31. doi: 10.20025/j.cnki.CN10-1679.2022-21-10 [3] 王庆宏, 郑逸, 李倩玮, 等.污染土壤生物联合修复机制研究进展[J]. 环境科学研究,2022,35(1):246-256. doi: 10.13198/j.issn.1001-6929.2021.10.16WANG Q H, ZHENG Y, LI Q W, et al. Overview of combined bioremediation mechanism of contaminated soil[J]. Research of Environmental Sciences,2022,35(1):246-256. doi: 10.13198/j.issn.1001-6929.2021.10.16 [4] 孙兴凯, 黄海, 王海东, 等.大型污染场地修复过程中的问题探讨与工程实践[J]. 环境工程技术学报,2020,10(5):883-890. doi: 10.12153/j.issn.1674-991X.20190216SUN X K, HUANG H, WANG H D, et al. Discussion of problems in the process of large-scale contaminate sites remediation and project practice[J]. Journal of Environmental Engineering Technology,2020,10(5):883-890. doi: 10.12153/j.issn.1674-991X.20190216 [5] 杨勇, 张蒋维, 陈恺, 等.化学氧化法治理焦化厂PAHs污染土壤[J]. 环境工程学报,2016,10(1):427-431. doi: 10.12030/j.cjee.20160171YANG Y, ZHANG J W, CHEN K, et al. Chemical oxidation of coking plant soils contaminated with polycyclic aromatic hydrocarbons[J]. Chinese Journal of Environmental Engineering,2016,10(1):427-431. doi: 10.12030/j.cjee.20160171 [6] PINO-HERRERA D O, PECHAUD Y, HUGUENOT D, et al. Removal mechanisms in aerobic slurry bioreactors for remediation of soils and sediments polluted with hydrophobic organic compounds: an overview[J]. Journal of Hazardous Materials,2017,339:427-449. doi: 10.1016/j.jhazmat.2017.06.013 [7] PLANGKLANG P, REUNGSANG A. Bioaugmentation of carbofuran by Burkholderia cepacia PCL3 in a bioslurry phase sequencing batch reactor[J]. Process Biochemistry,2010,45(2):230-238. doi: 10.1016/j.procbio.2009.09.013 [8] QUINTERO J C, MOREIRA M T, LEMA J M, et al. An anaerobic bioreactor allows the efficient degradation of HCH isomers in soil slurry[J]. Chemosphere,2006,63(6):1005-1013. doi: 10.1016/j.chemosphere.2005.08.043 [9] 吴蔓莉, 李可欣, 侯爽爽, 等.贫养分低有机质黄绵土中石油烃的生物去除特性及菌群结构变化[J]. 环境科学研究,2021,34(8):1961-1970. doi: 10.13198/j.issn.1001-6929.2021.04.13WU M L, LI K X, HOU S S, et al. Petroleum hydrocarbon degradation characteristics and microbial community shift by bioremediation in oligotrophic and low organic matter soil[J]. Research of Environmental Sciences,2021,34(8):1961-1970. doi: 10.13198/j.issn.1001-6929.2021.04.13 [10] NANO G, BORRONI A, ROTA R. Combined slurry and solid-phase bioremediation of diesel contaminated soils[J]. Journal of Hazardous Materials,2003,100(1/2/3):79-94. [11] ROBLES-GONZÁLEZ I V, FAVA F, POGGI-VARALDO H. A review on slurry bioreactors for bioremediation of soils and sediments[J]. Microbial Cell Factories,2008,7:5. doi: 10.1186/1475-2859-7-5 [12] VENKATA MOHAN S, PURUSHOTHAM REDDY B, SARMA P N. Ex situ slurry phase bioremediation of chrysene contaminated soil with the function of metabolic function: process evaluation by data enveloping analysis (DEA) and Taguchi design of experimental methodology (DOE)[J]. Bioresource Technology,2009,100(1):164-172. doi: 10.1016/j.biortech.2008.06.020 [13] MOSCA ANGELUCCI D, TOMEI M C. Ex situ bioremediation of chlorophenol contaminated soil: comparison of slurry and solid-phase bioreactors with the two-step polymer extraction-bioregeneration process[J]. Journal of Chemical Technology & Biotechnology,2016,91(6):1577-1584. [14] TYAGI M, Da FONSECA M M R, de CARVALHO C C C R. Bioaugmentation and biostimulation strategies to improve the effectiveness of bioremediation processes[J]. Biodegradation,2011,22(2):231-241. doi: 10.1007/s10532-010-9394-4 [15] WANG S Y, KUO Y C, HONG A, et al. Bioremediation of diesel and lubricant oil-contaminated soils using enhanced landfarming system[J]. Chemosphere,2016,164:558-567. doi: 10.1016/j.chemosphere.2016.08.128 [16] CASTALDI F J. Tank-based bioremediation of petroleum waste sludges[J]. Environmental Progress,2003,22(1):25-36. doi: 10.1002/ep.670220114 [17] ANTHES C, SCHUTTER O D. The Food and Agriculture Organization of the United Nations[R]. New York: United Nations, 2018. [18] LÜTZOW M V, KÖGEL-KNABNER I, EKSCHMITT K, et al. Stabilization of organic matter in temperate soils: mechanisms and their relevance under different soil conditions: a review[J]. European Journal of Soil Science,2006,57(4):426-445. doi: 10.1111/j.1365-2389.2006.00809.x [19] RAE J, PARKER A. Environmental interactions of clays[M]//Environmental Interactions of Clays. Berlin, Heidelberg: Springer Berlin Heidelberg, 1998: 1-6. [20] AYLMORE L A G, QUIRK J P. The micropore size distributions of clay mineral systems[J]. Journal of Soil Science,1967,18(1):1-17. doi: 10.1111/j.1365-2389.1967.tb01481.x [21] MÜLLER S, TOTSCHE K U, KÖGEL-KNABNER I. Sorption of polycyclic aromatic hydrocarbons to mineral surfaces[J]. European Journal of Soil Science,2007,58(4):918-931. doi: 10.1111/j.1365-2389.2007.00930.x [22] CUI X Y, HUNTER W, YANG Y, et al. Biodegradation of pyrene in sand, silt and clay fractions of sediment[J]. Biodegradation,2011,22(2):297-307. doi: 10.1007/s10532-010-9399-z [23] OEN A M P, CORNELISSEN G, BREEDVELD G D. Relation between PAH and black carbon contents in size fractions of Norwegian Harbor sediments[J]. Environmental Pollution,2006,141(2):370-380. doi: 10.1016/j.envpol.2005.08.033 [24] 綦远才, 周翠, 何欣芮, 等. 两种外源有机酸对土壤Cd形态及秋华柳Cd积累的影响[J]. 环境科学研究, 2021, 34(9): 2220-2227. doi: 10.13198/j.issn.1001-6929.2021.04.21QI Y C, ZHOU C, HE X R, et al. Effects of exogenous organic acids on Cd forms in soil and Cd accumulation in Salix variegate franch[J]. Research of Environmental Sciences, 2021, 34(9): 2220-2227. doi: 10.13198/j.issn.1001-6929.2021.04.21 [25] WERSHAW R L. A new model for humic materials and their interactions with hydrophobic organic chemicals in soil-water or sediment-water systems[J]. Journal of Contaminant Hydrology,1986,1(1/2):29-45. [26] TRELLU C, MILTNER A, GALLO R, et al. Characteristics of PAH tar oil contaminated soils: black particles, resins and implications for treatment strategies[J]. Journal of Hazardous Materials,2017,327:206-215. doi: 10.1016/j.jhazmat.2016.12.062 [27] CAO F S, BOURVEN I, LENS P N L, et al. Hydrophobic features of EPS extracted from anaerobic granular sludge: an investigation based on DAX-8 resin fractionation and size exclusion chromatography[J]. Applied Microbiology and Biotechnology,2017,101(8):3427-3438. doi: 10.1007/s00253-016-8053-z [28] ADAV S S, LEE D J. Extraction of extracellular polymeric substances from aerobic granule with compact interior structure[J]. Journal of Hazardous Materials,2008,154(1/2/3):1120-1126. [29] 展海银, 周启星.环境中四环素类抗生素污染处理技术研究进展[J]. 环境工程技术学报,2021,11(3):571-581. doi: 10.12153/j.issn.1674-991X.20200154ZHAN H Y, ZHOU Q X. Research progress on treatment technology of tetracycline antibiotics pollution in the environment[J]. Journal of Environmental Engineering Technology,2021,11(3):571-581. doi: 10.12153/j.issn.1674-991X.20200154 [30] AKSU Z. Application of biosorption for the removal of organic pollutants: a review[J]. Process Biochemistry,2005,40(3/4):997-1026. [31] VIJAYARAGHAVAN K, YUN Y S. Bacterial biosorbents and biosorption[J]. Biotechnology Advances,2008,26(3):266-291. doi: 10.1016/j.biotechadv.2008.02.002 [32] GARCIA-OCHOA F, GOMEZ E. Bioreactor scale-up and oxygen transfer rate in microbial processes: an overview[J]. Biotechnology Advances,2009,27(2):153-176. doi: 10.1016/j.biotechadv.2008.10.006 [33] SAPONARO S, BONOMO L, PETRUZZELLI G, et al. Polycyclic aromatic hydrocarbons (PAHs) slurry phase bioremediation of a manufacturing gas plant (MGP) site aged soil[J]. Water, Air, and Soil Pollution,2002,135(1):219-236. [34] MOZO I, LESAGE G, YIN J, et al. Dynamic modeling of biodegradation and volatilization of hazardous aromatic substances in aerobic bioreactor[J]. Water Research,2012,46(16):5327-5342. doi: 10.1016/j.watres.2012.07.014 [35] COLLINA E, BESTETTI G, Di GENNARO P, et al. Naphthalene biodegradation kinetics in an aerobic slurry-phase bioreactor[J]. Environment International,2005,31(2):167-171. doi: 10.1016/j.envint.2004.09.011 [36] HARITASH A K, KAUSHIK C P. Biodegradation aspects of polycyclic aromatic hydrocarbons (PAHs): a review[J]. Journal of Hazardous Materials,2009,169(1/2/3):1-15. [37] McGENITY T J. Hydrocarbon biodegradation in intertidal wetland sediments[J]. Current Opinion in Biotechnology,2014,27:46-54. doi: 10.1016/j.copbio.2013.10.010 [38] SPAIN J. Biodegradation of nitroaromatic compounds[R]. Cham: Springer, 2013. [39] HUSSAIN S, ARSHAD M, SPRINGAEL D, et al. Abiotic and biotic processes governing the fate of phenylurea herbicides in soils: a review[J]. Critical Reviews in Environmental Science and Technology,2015,45(18):1947-1998. doi: 10.1080/10643389.2014.1001141 [40] TIWARI M K, GUHA S. Kinetics of biotransformation of chlorpyrifos in aqueous and soil slurry environments[J]. Water Research,2014,51:73-85. doi: 10.1016/j.watres.2013.12.014 [41] BALSEIRO-ROMERO M, MONTERROSO C, KIDD P S, et al. Modelling the ex situ bioremediation of diesel-contaminated soil in a slurry bioreactor using a hydrocarbon-degrading inoculant[J]. Journal of Environmental Management,2019,246:840-848. [42] KARGI F. Re-interpretation of the logistic equation for batch microbial growth in relation to Monod kinetics[J]. Letters in Applied Microbiology,2009,48(4):398-401. doi: 10.1111/j.1472-765X.2008.02537.x [43] SKRDLA P J. A simple model for complex dissolution kinetics: a case study of norfloxacin[J]. Journal of Pharmaceutical and Biomedical Analysis,2007,45(2):251-256. doi: 10.1016/j.jpba.2007.06.012 [44] 曹斐姝, 陈建平, 谢冬燕, 等.泥浆生物反应器在土壤修复中的应用[J]. 环境工程,2022,40(4):174-181. doi: 10.13205/j.hjgc.202204025CAO F S, CHEN J P, XIE D Y, et al. Application of slurry bioreactor in soil remediation[J]. Environmental Engineering,2022,40(4):174-181. doi: 10.13205/j.hjgc.202204025 [45] ROBLES-GONZÁLEZ I, RÍOS-LEAL E, FERRERA-CERRATO R, et al. Bioremediation of a mineral soil with high contents of clay and organic matter contaminated with herbicide 2, 4-dichlorophenoxyacetic acid using slurry bioreactors: effect of electron acceptor and supplementation with an organic carbon source[J]. Process Biochemistry,2006,41(9):1951-1960. □ doi: 10.1016/j.procbio.2006.04.004 -

下载:

下载: