Mechanism of release of heavy metals in solidified/stabilized bodies of fly ash piperazine chelating agents

-

摘要:

生活垃圾焚烧飞灰中重金属对环境产生较大危害,而对其的固化/稳定化成为飞灰处理处置中的首要问题。用普通硅酸盐水泥处理垃圾焚烧飞灰较为普遍,为降低能耗提高产品效益,研究了新型大分子有机螯合剂哌嗪-N,N'-双二硫代羧酸钠(TS300)协同不同用量的水泥(30%、40%)固化飞灰中重金属的能力。探究了TS300对目标重金属Zn、Cd、Cr、Pb、Ni的浸出浓度、化学形态和微观结构的影响。结果表明:TS300协同水泥可有效固定飞灰中的重金属,降低浸出浓度60%以上;重金属Cr、Cd、Pb、Ni经固化后的化学形态整体向更稳定的方向移动;随着TS300和水泥添加量的增大,固化块晶体组成更稳定、抗酸强度上升且孔隙致密度增加,其中水泥添加量40%、TS300添加量8%的固化块重金属浸出浓度最低,固化效果最佳。综上,探究TS300协同水泥固化/稳定化重金属的效果和机理,有利于探究不同飞灰处理处置方式的优劣,分析水泥协同药剂固化稳定化飞灰重金属的效果,降低填埋场渗滤液的环境风险,为后续飞灰重金属螯合剂的研发提供新思路。

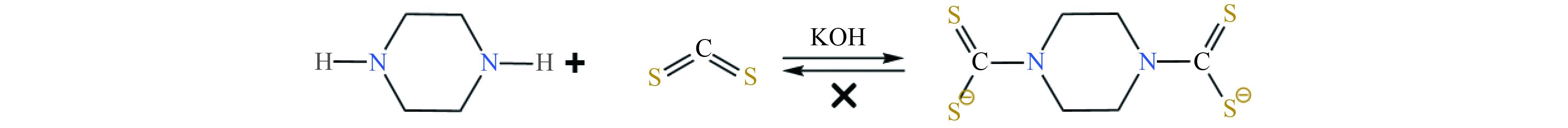

Abstract:Heavy metals in fly ash from municipal solid waste incineration are major environmental hazard, and their solidification/stabilization have become the primary problem in fly ash treatment and disposal. Portland cement is commonly used to treat waste incineration fly ash. In order to reduce energy consumption and improve product efficiency, the ability of a new macromolecular organic chelator, sodium piperazine-N,N'-bis-dithiocarboxylate (TS300), to solidify heavy metals in fly ash in concert with different amounts of cement (30%, 40%) was investigated. The effects of TS300 on the leaching concentration, chemical morphological changes, and microstructure of the target heavy metals Zn, Cd, Cr, Pb, and Ni were investigated. The results showed that TS300 co-cement could effectively immobilize the heavy metals in fly ash and reduce the leaching concentration by more than 60%. The chemical morphology of heavy metals Cr, Cd, Pb and Ni moved to a more stable direction overall after solidification. With the rise of TS300 and cement addition, curing block crystal composition, acid resistance strength, and pore density increased. The curing block with 40% addition of ordinary silicate cement and 8% addition of TS300 had the lowest heavy metal leaching concentration and the best curing effect. In summary, investigating the effect and mechanism of TS300 co-cement solidification/stabilization of heavy metals could analyze the effect of cement synergistic agents in curing and stabilizing fly ash heavy metals, reduce the environmental risk of landfill leachate, and provide new ideas for the subsequent research and development of fly ash heavy metal chelating agents.

-

Key words:

- fly ash /

- chelation /

- piperazine-N /

- N'-sodium dithiocarboxylate (TS300) /

- heavy metal /

- curing

-

表 1 飞灰中主要重金属浓度

Table 1. Main heavy metal contents in fly ash

mg/kg Zn Pb Cd Cr Ni Hg Be 4 050.33±29.91 713.36±24.23 188.41±3.99 58.33±1.57 31.18±0.92 27.01±0.53 0.22±0.06 表 2 固化块配比及参数

Table 2. Curing block ratio and parameters

样品编号 TS300用量/g 水泥用量/g 飞灰用量/g TS300占比/% F0 0 180 600 0 F1 6 180 600 1 F4 24 180 600 4 F8 48 180 600 8 G0 0 240 600 0 G1 6 240 600 1 G4 24 240 600 4 G8 48 240 600 8 -

[1] LU J W, ZHANG S K, HAI J, et al. Status and perspectives of municipal solid waste incineration in China: a comparison with developed regions[J]. Waste Management,2017,69:170-186. doi: 10.1016/j.wasman.2017.04.014 [2] 郭梦茹, 张冰如, 席佳锐, 等. 垃圾分类前后焚烧飞灰的理化性质及重金属污染特性[J]. 环境工程技术学报,2022,12(3):843-850.GUO M R, ZHANG B R, XI J R, et al. Physicochemical properties and heavy metal pollution characteristics of incineration fly ash before and after refuse classification[J]. Journal of Environmental Engineering Technology,2022,12(3):843-850. [3] 吴昊, 刘宏博, 田书磊, 等. 城市生活垃圾焚烧飞灰利用处置现状及环境管理[J]. 环境工程技术学报,2021,11(5):1034-1040. doi: 10.12153/j.issn.1674-991X.20210083WU H, LIU H B, TIAN S L, et al. Current situation for utilization and disposal and environmental management of fly ash from municipal solid waste incineration[J]. Journal of Environmental Engineering Technology,2021,11(5):1034-1040. doi: 10.12153/j.issn.1674-991X.20210083 [4] MAO Y P, WU H, WANG W L, et al. Pretreatment of municipal solid waste incineration fly ash and preparation of solid waste source sulphoaluminate cementitious material[J]. Journal of Hazardous Materials,2020,385:121580. doi: 10.1016/j.jhazmat.2019.121580 [5] MOLLICA G J G, BALESTIERI J A P. Is it worth generating energy with garbage: defining a carbon tax to encourage waste-to-energy cycles[J]. Applied Thermal Engineering,2020,173:115195. doi: 10.1016/j.applthermaleng.2020.115195 [6] VAVVA C, VOUTSAS E, MAGOULAS K. Process development for chemical stabilization of fly ash from municipal solid waste incineration[J]. Chemical Engineering Research and Design,2017,125:57-71. doi: 10.1016/j.cherd.2017.06.021 [7] 王庆旭, 李松, 吴昊, 等. 纳滤膜浓缩液淋滤焚烧飞灰过程中氯盐溶出及重金属的迁移特性[J]. 环境科学研究,2022,35(8):1958-1965. doi: 10.13198/j.issn.1001-6929.2022.04.01WANG Q X, LI S, WU H, et al. Characteristics of chloride salt dissolution and heavy metal migration during leaching of municipal solid waste incineration fly ash with membrane concentrate[J]. Research of Environmental Sciences,2022,35(8):1958-1965. doi: 10.13198/j.issn.1001-6929.2022.04.01 [8] WANG P, HU Y A, CHENG H F. Municipal solid waste (MSW) incineration fly ash as an important source of heavy metal pollution in China[J]. Environmental Pollution,2019,252:461-475. doi: 10.1016/j.envpol.2019.04.082 [9] BIE R S, CHEN P, SONG X F, et al. Characteristics of municipal solid waste incineration fly ash with cement solidification treatment[J]. Journal of the Energy Institute,2016,89(4):704-712. doi: 10.1016/j.joei.2015.04.006 [10] LIU S S, ZHAO S Y, LIANG Z H, et al. Perfluoroalkyl substances (PFASs) in leachate, fly ash, and bottom ash from waste incineration plants: implications for the environmental release of PFAS[J]. Science of the Total Environment,2021,795:148468. doi: 10.1016/j.scitotenv.2021.148468 [11] MINOCHA A K, JAIN N, VERMA C L. Effect of inorganic materials on the solidification of heavy metal sludge[J]. Cement and Concrete Research,2003,33(10):1695-1701. doi: 10.1016/S0008-8846(03)00146-7 [12] BENASSI L, PASQUALI M, ZANOLETTI A, et al. Chemical stabilization of municipal solid waste incineration fly ash without any commercial chemicals: first pilot-plant scaling up[J]. ACS Sustainable Chemistry & Engineering,2016,4(10):5561-5569. [13] BENASSI L, ZANOLETTI A, DEPERO L E, et al. Sewage sludge ash recovery as valuable raw material for chemical stabilization of leachable heavy metals[J]. Journal of Environmental Management,2019,245:464-470. [14] LI J T, ZENG M, JI W X. Characteristics of the cement-solidified municipal solid waste incineration fly ash[J]. Environmental Science and Pollution Research,2018,25(36):36736-36744. doi: 10.1007/s11356-018-3600-z [15] WANG F H, ZHANG F, CHEN Y J, et al. A comparative study on the heavy metal solidification/stabilization performance of four chemical solidifying agents in municipal solid waste incineration fly ash[J]. Journal of Hazardous Materials,2015,300:451-458. doi: 10.1016/j.jhazmat.2015.07.037 [16] CHEN S S, HUANG J L, XIAO T T, et al. Carbon emissions under different domestic waste treatment modes induced by garbage classification: case study in pilot communities in Shanghai, China[J]. Science of the Total Environment,2020,717:137193. doi: 10.1016/j.scitotenv.2020.137193 [17] MA Y, WANG G, YE G, et al. A comparative study on the pore structure of alkali-activated fly ash evaluated by mercury intrusion porosimetry, N2 adsorption and image analysis[J]. Journal of Materials Science,2018,53(8):5958-5972. doi: 10.1007/s10853-017-1965-x [18] CUDJOE D, ACQUAH P M. Environmental impact analysis of municipal solid waste incineration in African countries[J]. Chemosphere,2021,265:129186. doi: 10.1016/j.chemosphere.2020.129186 [19] LUO Z T, TANG C B, HAO Y H, et al. Solidification/stabilization of heavy metals and its efficiency in lead–zinc tailings using different chemical agents[J]. Environmental Technology,2022,43(11):1613-1623. doi: 10.1080/09593330.2020.1845817 [20] ZHU J R, ZHENG H L, JIANG Z Z, et al. Synthesis and characterization of a dewatering reagent: cationic polyacrylamide (P(AM–DMC–DAC)) for activated sludge dewatering treatment[J]. Desalination and Water Treatment,2013,51(13/14/15):2791-2801. [21] BHATTACHARJEE A, MANDAL H, ROY M, et al. Microstructural and magnetic characterization of fly ash from Kolaghat Thermal Power Plant in West Bengal, India[J]. Journal of Magnetism and Magnetic Materials,2011,323(23):3007-3012. doi: 10.1016/j.jmmm.2011.06.036 [22] XUE F, WEI X, DONG J H, et al. Effect of chloride ion on corrosion behavior of low carbon steel in 0.1 M NaHCO3 solution with different dissolved oxygen concentrations[J]. Journal of Materials Science & Technology,2019,35(4):596-603. [23] PADMI T, TANAKA M, AOYAMA I. Chemical stabilization of medical waste fly ash using chelating agent and phosphates: heavy metals and ecotoxicity evaluation[J]. Waste Management,2009,29(7):2065-2070. doi: 10.1016/j.wasman.2009.03.005 [24] MA W C, CHEN D M, PAN M H, et al. Performance of chemical chelating agent stabilization and cement solidification on heavy metals in MSWI fly ash: a comparative study[J]. Journal of Environmental Management,2019,247:169-177. [25] HU L, WU Z, XU J X, et al. Zeolite-promoted transformation of glucose into 5-hydroxymethylfurfural in ionic liquid[J]. Chemical Engineering Journal,2014,244:137-144. doi: 10.1016/j.cej.2014.01.057 [26] LIU Y Q, SHI J J. Corrosion resistance of carbon steel in alkaline concrete pore solutions containing phytate and chloride ions[J]. Corrosion Science,2022,205:110451. doi: 10.1016/j.corsci.2022.110451 [27] DU B, LI J T, FANG W, et al. Comparison of long-term stability under natural ageing between cement solidified and chelator-stabilised MSWI fly ash[J]. Environmental Pollution,2019,250:68-78. doi: 10.1016/j.envpol.2019.03.124 [28] ZHAO Y C, SONG L J, LI G J. Chemical stabilization of MSW incinerator fly ashes[J]. Journal of Hazardous Materials,2002,95(1/2):47-63. [29] ZHANG Q, YE G, KOENDERS E. Investigation of the structure of heated Portland cement paste by using various techniques[J]. Construction and Building Materials,2013,38:1040-1050. doi: 10.1016/j.conbuildmat.2012.09.071 [30] SHAO Y, HOU H B, WANG G X, et al. Characteristics of the stabilized/solidified municipal solid wastes incineration fly ash and the leaching behavior of Cr and Pb[J]. Frontiers of Environmental Science & Engineering,2016,10(1):192-200. [31] XU J Z, ZHOU Y L, CHANG Q, et al. Study on the factors of affecting the immobilization of heavy metals in fly ash-based geopolymers[J]. Materials Letters,2006,60(6):820-822. doi: 10.1016/j.matlet.2005.10.019 [32] ECKE H, SAKANAKURA H, MATSUTO T, et al. State-of-the-art treatment processes for municipal solid waste incineration residues in Japan[J]. Waste Management and Research,2000,18(1):41-51. doi: 10.1177/0734242X0001800106 [33] MA Y, LIU Z H, XU Y Q, et al. Remediating potentially toxic metal and organic co-contamination of soil by combining in situ solidification/stabilization and chemical oxidation: efficacy, mechanism, and evaluation[J]. International Journal of Environmental Research and Public Health,2018,15(11):2595. doi: 10.3390/ijerph15112595 [34] SANTOS A R, DO ROSÁRIO VEIGA M, SANTOS SILVA A, et al. Microstructure as a critical factor of cement mortars' behaviour: the effect of aggregates' properties[J]. Cement and Concrete Composites,2020,111:103628. doi: 10.1016/j.cemconcomp.2020.103628 [35] ZHAN X Y, KIRKELUND G M. Electrodialytic remediation of municipal solid waste incineration fly ash as pre-treatment before geopolymerisation with coal fly ash[J]. Journal of Hazardous Materials,2021,412:125220. doi: 10.1016/j.jhazmat.2021.125220 [36] LIU B, YANG Q W, ZHANG S G. Integrated utilization of municipal solid waste incineration fly ash and bottom ash for preparation of foam glass-ceramics[J]. Rare Metals,2019,38(10):914-921. doi: 10.1007/s12598-019-01314-2 [37] KAUR R, GOYAL D. Mineralogical studies of coal fly ash for soil application in agriculture[J]. Particulate Science and Technology,2015,33(1):76-80. doi: 10.1080/02726351.2014.938378 [38] ZHANG Y A, WANG L J, TANG B T, et al. Form-stable phase change materials with high phase change enthalpy from the composite of paraffin and cross-linking phase change structure[J]. Applied Energy,2016,184:241-246. doi: 10.1016/j.apenergy.2016.10.021 [39] FAN C C, WANG B M, AI H M, et al. A comparative study on solidification/stabilization characteristics of coal fly ash-based geopolymer and Portland cement on heavy metals in MSWI fly ash[J]. Journal of Cleaner Production,2021,319:128790. doi: 10.1016/j.jclepro.2021.128790 [40] BUI VIET D, CHAN W P, PHUA Z H, et al. The use of fly ashes from waste-to-energy processes as mineral CO2 sequesters and supplementary cementitious materials[J]. Journal of Hazardous Materials,2020,398:122906. doi: 10.1016/j.jhazmat.2020.122906 [41] XIE K, HU H Y, XU S H, et al. Fate of heavy metals during molten salts thermal treatment of municipal solid waste incineration fly ashes[J]. Waste Management,2020,103:334-341. doi: 10.1016/j.wasman.2019.12.047 [42] 宋珍霞, 王里奥, 林祥, 等. 城市垃圾焚烧飞灰特性及水泥固化试验研究[J]. 环境科学研究,2008,21(4):163-168.SONG Z X, WANG L A, LIN X, et al. Experimental study on properties and cement solidification of municipal solid waste incineration fly ash[J]. Research of Environmental Sciences,2008,21(4):163-168. [43] WANG Y T, XU H Y, CHEN C, et al. Enhanced solidification/stabilization of lead in MSWI fly ash treatment and disposal by gelatinized sticky rice[J]. Environmental Technology,2021,42(10):1531-1541. doi: 10.1080/09593330.2019.1673828 [44] ZHAO Y K, WANG Z Y, ZHANG B R, et al. Performance and mechanism of copper removal from wastewater by sodium tetraethylenepentamine-N, N', N'', N''', N''''-pentadithiocarboxylic acid[J]. Journal of Molecular Structure,2021,1242:130727. doi: 10.1016/j.molstruc.2021.130727 [45] ZHANG M L, GUO M R, ZHANG B R, et al. Stabilization of heavy metals in MSWI fly ash with a novel dithiocarboxylate-functionalized polyaminoamide dendrimer[J]. Waste Management,2020,105:289-298. doi: 10.1016/j.wasman.2020.02.004 [46] TIAN S C, JIANG J G, ZHANG C. Influence of flue gas SO2 on the toxicity of heavy metals in municipal solid waste incinerator fly ash after accelerated carbonation stabilization[J]. Journal of Hazardous Materials,2011,192(3):1609-1615. doi: 10.1016/j.jhazmat.2011.06.085 [47] PRABHAKAR A K, CADIAM MOHAN B, TAY T S, et al. Incinerated sewage sludge bottom ash: chemical processing, leaching patterns and toxicity testing[J]. Journal of Hazardous Materials,2021,402:123350. doi: 10.1016/j.jhazmat.2020.123350 [48] SUN Y Y, XU C B, YANG W J, et al. Evaluation of a mixed chelator as heavy metal stabilizer for municipal solid-waste incineration fly ash: behaviors and mechanisms[J]. Journal of the Chinese Chemical Society,2019,66(2):188-196. doi: 10.1002/jccs.201700406 [49] MEHTA A, SIDDIQUE R. Strength, permeability and micro-structural characteristics of low-calcium fly ash based geopolymers[J]. Construction and Building Materials,2017,141:325-334. doi: 10.1016/j.conbuildmat.2017.03.031 [50] HUANG Z X, FAN M H, TIAN H J. Rare earth elements of fly ash from Wyoming's Powder River Basin coal[J]. Journal of Rare Earths,2020,38(2):219-226. doi: 10.1016/j.jre.2019.05.004 [51] LEE B, LEE S, KIM B, et al. Advanced characterization of IGCC slag by automated SEM-EDS analysis[J]. Waste Management,2020,116:140-146. doi: 10.1016/j.wasman.2020.08.001 [52] KUMAR S, KRISTÁLY F, MUCSI G. Geopolymerisation behaviour of size fractioned fly ash[J]. Advanced Powder Technology,2015,26(1):24-30. doi: 10.1016/j.apt.2014.09.001 [53] WANG T, ISHIDA T, GU R. A study of the influence of crystal component on the reactivity of low-calcium fly ash in alkaline conditions based on SEM-EDS[J]. Construction and Building Materials,2020,243:118227. doi: 10.1016/j.conbuildmat.2020.118227 [54] WANG T, ISHIDA T, GU R, et al. Experimental investigation of pozzolanic reaction and curing temperature-dependence of low-calcium fly ash in cement system and Ca-Si-Al element distribution of fly ash-blended cement paste[J]. Construction and Building Materials,2021,267:121012. doi: 10.1016/j.conbuildmat.2020.121012 [55] 黄文有, 孟月东, 陈明周, 等. 等离子体熔融生活垃圾焚烧飞灰中试试验[J]. 环境工程技术学报,2016,6(5):501-508.HUANG W Y, MENG Y D, CHEN M Z, et al. Pilot scale study on plasma vitrification of municipal waste incinerator fly ash[J]. Journal of Environmental Engineering Technology,2016,6(5):501-508. [56] JOHANSEN V, ANDERSEN P J. Particle packing and concrete properties[J]. Materials Science of Concrete Ⅱ,1991,88:246-271. [57] GOLTERMANN P, JOHANSEN V , PALBØL L. Packing of aggregates: an alternative tool to determine the optimal aggregate mix[J]. ACI Materials Journal, 1997, 94(5): 435-443. [58] ZHAO H T, QIN X, LIU J P, et al. Pore structure characterization of early-age cement pastes blended with high-volume fly ash[J]. Construction and Building Materials,2018,189:934-946. doi: 10.1016/j.conbuildmat.2018.09.023 [59] NEDELJKOVIĆ M, ŠAVIJA B, ZUO Y B, et al. Effect of natural carbonation on the pore structure and elastic modulus of the alkali-activated fly ash and slag pastes[J]. Construction and Building Materials,2018,161:687-704. □ doi: 10.1016/j.conbuildmat.2017.12.005 -

下载:

下载: