Numerical simulation study on flow field optimization of electrostatic precipitator inlet flue duct in coal-fired units

-

摘要:

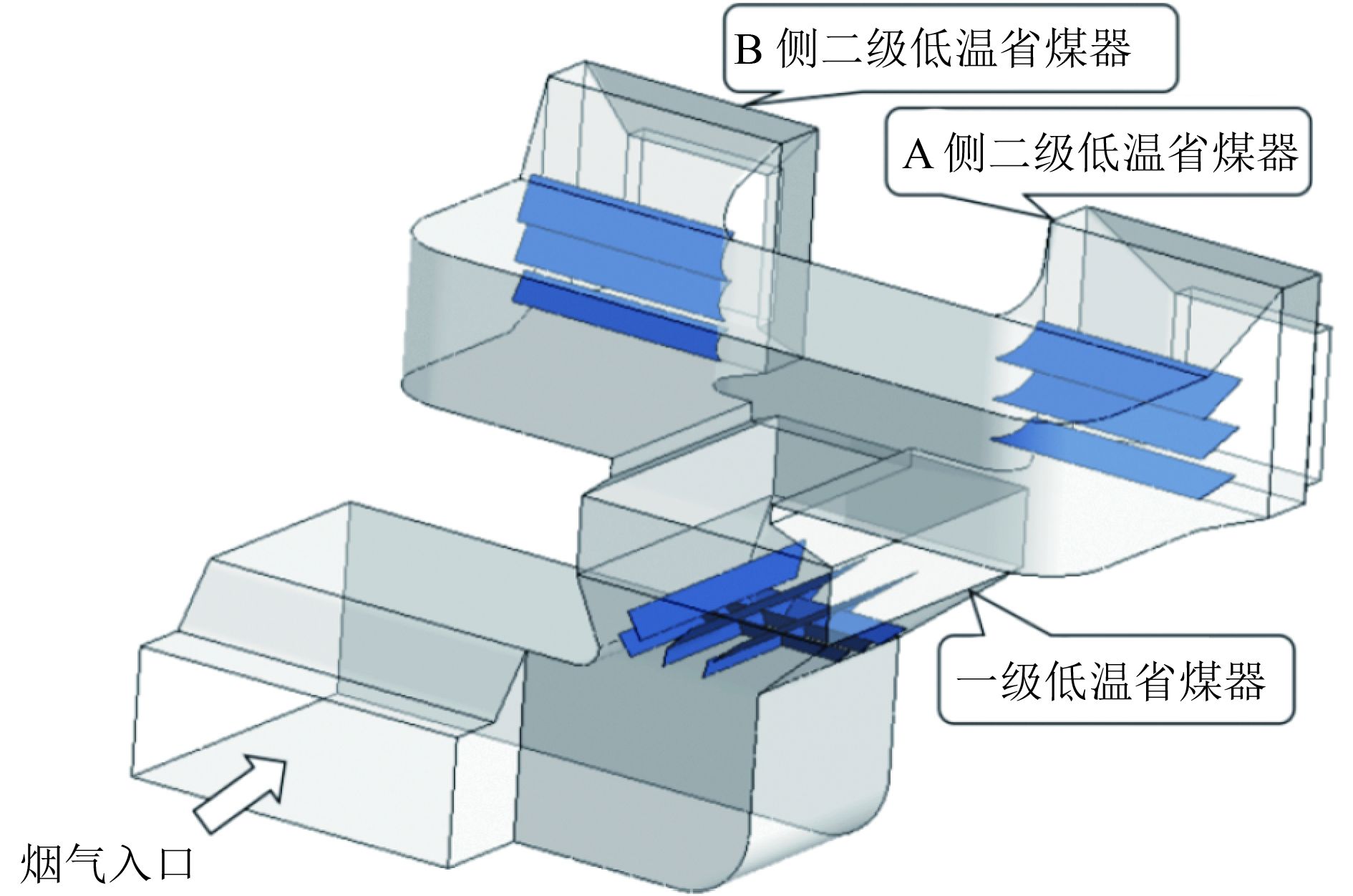

燃煤机组环保设施连接烟道阻力增加是风机能耗增大的主要因素之一,对烟道进行流场优化,降低烟道阻力和风机能耗是燃煤电厂节能降耗的有效途径之一。采用CFD数值模拟对某电厂660 MW燃煤机组电除尘器入口烟道进行流场优化,重点分析了5种不同优化方案下烟道阻力、风机能耗、灰质量流量分配比例、烟气灰浓度、导流板磨损速率等参数的变化规律。结果表明:通过设置合理结构形式及数量的导流板实现烟道降阻幅度28.7%,单台机组最大可节约风机能耗190 kW·h,节能降耗效果显著。新增导流板对烟气中灰质量流量分配比例具有调节作用,优化后A、B两侧烟道内灰质量流量比例偏差由14.8%降低至6.6%,提高了电除尘器的综合除尘率。烟道流场优化在改善灰浓度场分布的同时降低了导流板的磨损,优化后导流板的平均磨损速率由1.33×10−7 kg/(m2·s)降低至0.56×10−7 kg/(m2·s),降幅高达57.6%,导流板使用寿命是优化前的2.4倍,提高了机组运行的安全性和可靠性。

Abstract:Resistance increase of connecting flue ducts between environmental protection facilities is one of the main factors influencing fan energy consumption increase in coal-fired units. Accordingly, it is an effective method of saving energy and reducing consumption to optimize the flow field of flue ducts and to reduce resistance and fan energy consumption in coal-fired power plants. CFD numerical simulation was applied to optimize the inlet flue duct of the electrostatic precipitator in a 660 MW coal-fired unit. The varying rules of flue duct resistance, fan energy consumption, ash mass flow distribution, ash concentration and guiding plates wearing rate were studied with a comparative analysis of five different schemes. The results showed that the flue duct resistance was reduced by 28.7% through setting reasonable structural form and quantity of guiding plates. A maximum fan energy consumption of 190 kW·h could be saved for a single unit, and the energy saving and consumption reduction were remarkable. The addition of guiding plates could regulate the distribution ratio of ash mass flow in the flue gas. After optimization, the deviation of ash mass flow distribution ratio reduced from 14.8% to 6.6% on sides A and B, which improved the comprehensive removal efficiency of dust particles by electrostatic precipitator. The optimization of the flue flow field not only improved the uniformity of ash concentration field distribution, but also reduced the wearing rate of guiding plates. After optimization, the average wearing rate of guiding plates decreased from 1.33×10−7 to 0.56×10−7 kg/(m2·s), with a decrease of 57.6%. The service life of guiding plates was 2.4 times that before optimization, and the safety and reliability of the unit operation improved.

-

表 1 烟道优化方案

Table 1. Flue duct optimization scheme

序号 具体方案 方案一 基准方案(未优化前的原始烟道) 方案二 位置③、⑦、⑧安装弧形导流板 方案三 位置③、⑦、⑧安装弧形导流板,位置①倒圆角 方案四 位置③、⑦、⑧安装弧形导流板,位置①倒圆角,

位置④更换格栅方案五 位置③、⑦、⑧安装弧形导流板,位置①倒圆角,位置④更换格栅,位置②安装弧形导流板 方案六 位置③、⑦、⑧安装弧形导流板,位置①倒圆角,位置④更换格栅,位置②安装弧形导流板,

位置⑤、⑥安装弧形导流板 -

[1] 陶莉, 肖育军. SCR区域喷氨的NH3分布与均匀性调整[J]. 环境工程技术学报, 2021, 11(4): 663-669.TAO L, XIAO Y J. NH3 distribution and uniformity adjustment of ammonia spray in SCR area[J]. Journal of Environmental Engineering Technology, 2021, 11(4): 663-669. [2] 钟洪玲, 陈鸥, 王洪亮, 等.超低排放下燃煤电厂氨排放特征[J]. 环境科学研究,2021,34(1):124-131. doi: 10.13198/j.issn.1001-6929.2020.11.24ZHONG H L, CHEN O, WANG H L, et al. Characteristics of ammonia emission in flue gas from ultra-low emission coal-fired power plants[J]. Research of Environmental Sciences,2021,34(1):124-131. doi: 10.13198/j.issn.1001-6929.2020.11.24 [3] 孙志鹏. 300 MW燃煤机组电除尘器前烟道流场CFD仿真与优化[J/OL]. 洁净煤技术. [2021-12-28]. https://kns.cnki.net/kcms/detail/detail.aspx?dbcode=CAPJ&dbname=CAPJLAST&filename=JJMS20210112000&uniplatform=NZKPT&v=zFgFmBHRGGjAJJ7KXIBcj7DW31y2bbW8iG_hDK-BSIzoY8PF07QYFzcgKMNfBlRP.SUN Z P. CFD simulation and optimization of flow field in front flue of electric precipitator in a 300 MW coal-fired unit[J/OL]. Clean Coal Technology. [2021-12-28]. https://kns.cnki.net/kcms/detail/detail.aspx?dbcode=CAPJ&dbname=CAPJLAST&filename=JJMS20210112000&uniplatform=NZKPT&v=zFgFmBHRGGjAJJ7KXIBcj7DW31y2bbW8iG_hDK-BSIzoY8PF07QYFzcgKMNfBlRP. [4] 赵海晓.600 MW超临界机组尾部烟道流场优化[J]. 浙江电力,2021,40(2):99-104.ZHAO H X. Optimization of flow field in tail flue of 600 MW supercritical unit[J]. Zhejiang Electric Power,2021,40(2):99-104. [5] 李凯伦, 孙大伟, 朱红伟, 等.600 MW火电机组烟道优化[J]. 热力发电,2017,46(4):120-124. doi: 10.3969/j.issn.1002-3364.2017.04.120LI K L, SUN D W, ZHU H W, et al. Optimization of flue duct for a 600 MW thermal power unit[J]. Thermal Power Generation,2017,46(4):120-124. doi: 10.3969/j.issn.1002-3364.2017.04.120 [6] 柏源, 陈俊, 薛建明.600 MW等级燃煤机组烟道流场数值模拟与优化[J]. 电力科技与环保,2019,35(1):19-21. doi: 10.3969/j.issn.1674-8069.2019.01.007BAI Y, CHEN J, XUE J M. Numerical simulation and optimization for flue flow field of 600 MW coal-fired unit[J]. Electric Power Technology and Environmental Protection,2019,35(1):19-21. doi: 10.3969/j.issn.1674-8069.2019.01.007 [7] 马海彦, 周雷, 王庭文, 等.1 060 MW燃煤机组烟道流场性能诊断与优化[J]. 发电技术,2018,39(3):253-258. doi: 10.12096/j.2096-4528.pgt.2018.039MA H Y, ZHOU L, WANG T W, et al. Performance diagnosis and optimization of flue flow field of 1 060 MW coal-fired unit[J]. Power Generation Technology,2018,39(3):253-258. doi: 10.12096/j.2096-4528.pgt.2018.039 [8] 李巩, 叶兴联, 张浩, 等.SCR脱硝后低温省煤器磨损分析及结构优化[J]. 应用力学学报,2021,38(5):2049-2056. doi: 10.11776/cjam.38.05.A009LI G, YE X L, ZHANG H, et al. Wear analysis and structural optimization of low temperature economizer after SCR denitrification[J]. Chinese Journal of Applied Mechanics,2021,38(5):2049-2056. doi: 10.11776/cjam.38.05.A009 [9] 牛国平, 周梦伟, 杨晓刚, 等.飞灰分布对烟冷器的磨损研究及工程实践[J]. 热力发电,2021,50(5):139-146. doi: 10.19666/j.rlfd.202006185NIU G P, ZHOU M W, YANG X G, et al. Research and engineering practice for the effect of fly ash distribution on wear of flue gas cooler[J]. Thermal Power Generation,2021,50(5):139-146. doi: 10.19666/j.rlfd.202006185 [10] 张智雄. 卧式滤筒除尘器结构改进的数值模拟[D]. 长沙: 湖南大学, 2021. [11] 邓晓川, 胡龙彬, 李斌, 等.1 000 MW机组低温省煤器及烟道流场模拟优化研究[J]. 洁净煤技术,2019,25(6):158-164.DENG X C, HU L B, LI B, et al. Simulation and optimization study of low temperature economizer and flue flow field of 1 000 MW unit[J]. Clean Coal Technology,2019,25(6):158-164. [12] 莫逊, 朱冬生, 叶周, 等.电厂燃煤锅炉局部烟道导流装置设计优化[J]. 洁净煤技术,2021,27(5):180-188. doi: 10.13226/j.issn.1006-6772.20042001MO X, ZHU D S, YE Z, et al. Design and optimization of local flue guide plate of coal-fired boiler in power plant[J]. Clean Coal Technology,2021,27(5):180-188. doi: 10.13226/j.issn.1006-6772.20042001 [13] 马鹏飞, 张选, 贾瑞龙, 等.电厂烟道烟气流动计算仿真及流量均衡研究[J]. 工业安全与环保,2021,47(3):83-86. doi: 10.3969/j.issn.1001-425X.2021.03.019MA P F, ZHANG X, JIA R L, et al. The research of numerical simulation and flowrate balance of flue gas flow in flue ducts of power plant[J]. Industrial Safety and Environmental Protection,2021,47(3):83-86. doi: 10.3969/j.issn.1001-425X.2021.03.019 [14] 张立贤, 刘庆鑫.烟风道布置低温省煤器流场均匀性分析[J]. 东北电力大学学报,2020,40(3):88-92. doi: 10.19718/j.issn.1005-2992.2020-03-0088-05 [15] 刘荣堂, 王宇, 刘明, 等.燃煤电站除尘器前烟道磨损特性与优化研究[J]. 工程热物理学报,2019,40(4):808-812.LIU R T, WANG Y, LIU M, et al. Investigation and optimization on erosion characteristics of the flue gas pipe before the dust collector in power plants[J]. Journal of Engineering Thermophysics,2019,40(4):808-812. [16] 肖育军, 李彩亭, 李珊红, 等.旋风-喷射鼓泡塔的结构特征与性能分析[J]. 环境工程技术学报,2019,9(2):126-132. doi: 10.12153/j.issn.1674-991X.2018.12.200XIAO Y J, LI C T, LI S H, et al. Structure characteristics and performance analysis of a novel cyclone-jet bubbling tower[J]. Journal of Environmental Engineering Technology,2019,9(2):126-132. doi: 10.12153/j.issn.1674-991X.2018.12.200 [17] 周梦伟, 牛国平, 贾光瑞, 等.烟气飞灰对锅炉尾部烟道磨损数值模拟[J]. 热力发电,2019,48(8):62-67. doi: 10.19666/j.rlfd.201903051ZHOU M W, NIU G P, JIA G R, et al. Numerical simulation of fly ash erosion on bolier tail flue channel[J]. Thermal Power Generation,2019,48(8):62-67. doi: 10.19666/j.rlfd.201903051 [18] 王珍, 曹文广, 彭维明.电除尘器上下游烟道流场分析及优化设计[J]. 环境工程学报,2016,10(12):7183-7187. doi: 10.12030/j.cjee.201510056WANG Z, CAO W G, PENG W M. Numerical simulation and optimizing design of gas-flow distribution of electrostatic precipitator[J]. Chinese Journal of Environmental Engineering,2016,10(12):7183-7187. doi: 10.12030/j.cjee.201510056 [19] 蒋华, 蒲万里, 陈欣.燃煤电站锅炉尾部烟道阻力特性数值模拟和优化研究[J]. 锅炉技术,2021,52(4):16-19. doi: 10.3969/j.issn.1672-4763.2021.04.004JIANG H, PU W L, CHEN X. Numerical simulation and optimization on resistance characteristics of boiler flue gas ducts in coal fired power plant[J]. Boiler Technology,2021,52(4):16-19. doi: 10.3969/j.issn.1672-4763.2021.04.004 [20] 邓庆波, 冉景煜, 杨仲卿, 等.湿法脱硫塔入口烟气调温耦合余热回收工艺系统节能分析比较[J]. 中国电机工程学报,2020,40(23):7667-7675. doi: 10.13334/J.0258-8013.PCSEE.200781DENG Q B, RAN J Y, YANG Z Q, et al. Energy saving analysis and comparison of flue gas temperature regulation coupling waste heat recovery process system at the entrance of wet desulfurization tower[J]. Proceedings of the CSEE,2020,40(23):7667-7675. □ doi: 10.13334/J.0258-8013.PCSEE.200781 -

下载:

下载: