Study on pollution characteristics and environmental risk of coal coking residues

-

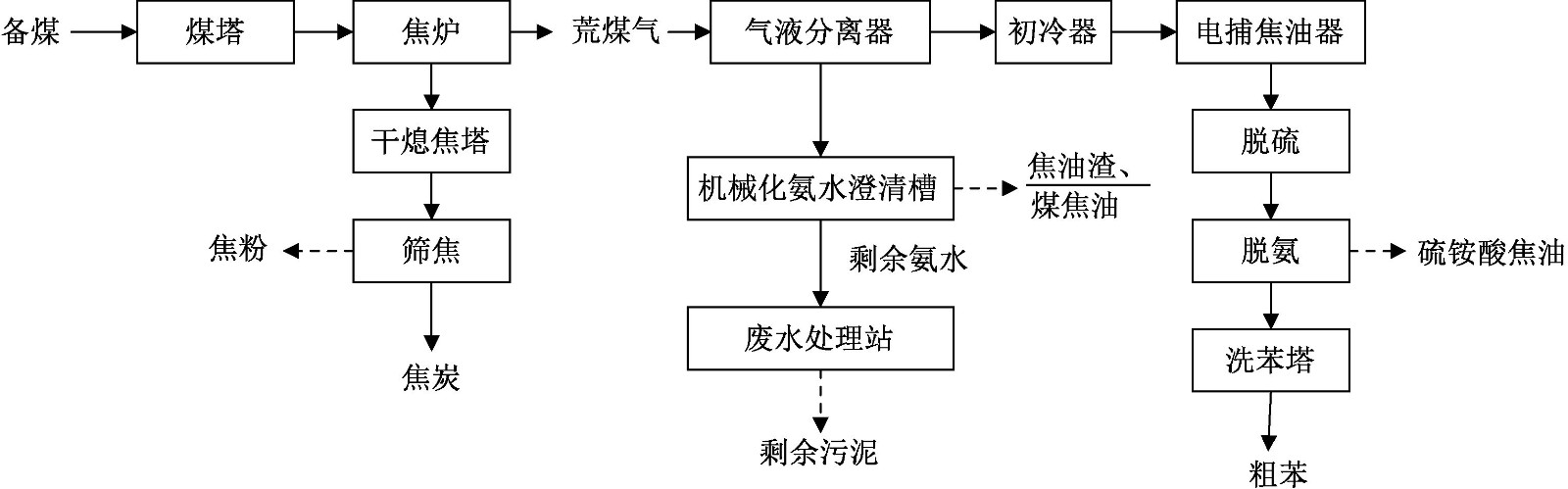

摘要: 以某煤焦化企业生产过程产生的焦油渣、煤焦油、硫铵酸焦油、焦粉、剩余污泥5种残渣为研究对象,采用气相色谱-质谱联用仪分析残渣中16种优先控制的多环芳烃(PAHs)浓度和环数分布,采用电感耦合等离子体质谱仪测定8种重金属浓度,通过计算残渣的苯并[a]芘(BaP)等效毒性和重金属潜在生态危害指数分析煤焦化残渣的环境风险。结果表明,5种残渣的PAHs总浓度为0.94~238 367 mg/kg,表现为煤焦油>焦油渣>硫铵酸焦油>焦粉>剩余污泥,焦油渣、煤焦油、硫铵酸焦油中高致突变性物质、致癌性物质浓度超过GB 5085.6—2007《危险废物鉴别标准 毒性物质含量鉴别》标准限值;焦油渣、煤焦油、焦粉、剩余污泥中Zn浓度最高,硫铵酸焦油中As浓度最高;5种残渣的BaP等效毒性为0.31~9 586.96 mg/kg,煤焦油、焦油渣、硫铵酸焦油具有更高的致癌风险;Hg是5种残渣中潜在环境风险最大的重金属,5种残渣对土壤均具有很强的潜在生态风险。Abstract: The tar slag, coal tar, ammonium sulfate tar, coke powder and residual sludge were collected from a coal coking enterprise. The concentrations and different ring distribution of 16 priority controlled polycyclic aromatic hydrocarbons (PAHs) were analyzed by gas chromatography-mass spectrometry (GC-MS), and 8 heavy metals were analyzed by inductively coupled plasma mass spectrometry (ICP-MS). Meanwhile, the environmental risks of coal coking residues were analyzed by calculating the BaP equivalent toxicity concentration and the potential ecological risk index of heavy metals. The results showed that the total PAHs concentrations of five residues ranged from 0.94 mg/kg to 238 367 mg/kg, with the order of coal tar > tar slag > ammonium sulfate tar > coke powder > residual sludge, and the concentrations of highly mutagenic and carcinogenic compounds in tar slag, coal tar and ammonium sulfate tar exceeded the limits of Identification Standards for Hazardous Wastes- Identification for Toxic Substance Content (GB 5085.6—2007). The concentration of Zn in tar slag, coal tar, coke powder and residual sludge was the highest, and ammonium sulfate tar had the highest concentration of As. The BaP equivalent toxic concentration of the five residues was 0.31-9 586.96 mg/kg, and coal tar, tar slag and ammonium sulfate tar had higher cancer risk. Hg had the highest potential environmental risk among the five residues, and all the five residues had a strong potential ecological risk to the soil.

-

Key words:

- coal coking residue /

- PAHs /

- heavy metal /

- environmental risk

-

表 1 潜在生态风险评价等级划分标准

Table 1. Classification criteria for potential ecological risk assessment

${E}_{{\rm{j}}}^{i}$ 单种重金属生态

风险程度$ \mathrm{R}\mathrm{I} $ 重金属综合潜在

生态风险程度<40 轻微 <150 轻微 40~80 中等 150~300 中等 80~160 强 300~600 强 160~320 很强 ≥600 很强 ≥320 极强 表 2 煤焦化残渣的PAHs等效致癌毒性

Table 2. PAHs equivalent carcinogenic toxicity of residues from coal coking process

mg/kg PAHs TEF 煤焦油 焦油渣 硫铵酸焦油 焦粉 剩余污泥 Nap 0.001 102.96 39.43 19.12 — — Ace 0.001 17.41 8.44 5.44 — — Acy 0.001 1.29 0.52 0.20 — — Flu 0.001 16.71 6.38 2.29 — — Phe 0.001 0.46 0.19 2.77 0.01 — Ant 0.01 118.39 51.52 7.68 0.02 — Fla 0.001 27.39 12.64 1.54 0.01 — Pyr 0.001 18.37 6.94 0.97 0.01 — BaA 0.1 1 007.90 379.40 132.00 0.46 — Chr 0.001 9.10 3.65 1.16 — — BbF 0.1 667.70 250.60 82.60 0.40 0.03 BkF 0.1 496.20 197.50 65.20 0.33 — BaP 1 6 008.00 2 36.00 672.00 3.94 0.28 InP 0.1 236.90 102.80 30.70 0.18 — DahA 1 839.00 290.00 98.00 1.11 — BghiP 0.01 19.20 7.96 1.94 0.02 — ΣBEQ — 9 586.96 3 716.97 1 123.62 6.48 0.31 注:—表示未检出或浓度低于1.0×10−2 mg/kg。 表 3 煤焦化残渣中8种重金属浓度

Table 3. Concentrations of 8 heavy metals in coal coking residues

mg/kg 项目 Cu Pb Zn Ni Hg Cd Cr As 总量 焦油渣 9.40±2.37 137.00±12.50 420.00±68.55 4.30±0.50 0.60±0.10 3.50±0.75 8.20±0.85 0.68±0.12 583.68±85.71 煤焦油 0.60±0.10 42.50±4.18 46.60±6.01 — 0.43±0.05 0.90±0.25 0.80±0.19 0.44±0.05 92.27±10.80 硫铵酸焦油 8.30±1.31 — 4.30±0.81 21.80±2.41 1.75±0.36 0.10±0.06 14.30±1.36 39.60±6.56 90.15±12.82 焦粉 29.70±4.17 31.00±3.51 122.00±11.02 14.40±2.64 0.60±0.11 0.20±0.07 30.00±5.61 6.24±0.44 234.14±27.48 剩余污泥 26.80±4.04 4.90±0.75 90.20±7.61 8.00±1.17 1.27±0.16 — 23.50±3.31 3.24±0.78 157.91±17.75 济南市土壤背景值[17] 25.10 24.10 68.40 30.10 0.04 0.15 68.50 10.40 226.79 注:—表示未检出。 表 4 煤焦化残渣重金属潜在生态危害指数

Table 4. Potential ecological risk index of heavy metals in coal coking residues

项目 单因子潜在生态危害指数 RI Cu Pb Zn Ni Hg Cd Cr As 焦油渣 1.87 28.42 6.14 0.71 600.00 700.00 0.24 0.65 1 338.04 煤焦油 0.12 8.82 0.68 — 430.00 180.00 0.02 0.42 620.06 硫铵酸焦油 1.65 — 0.06 3.62 1 750.00 20.00 0.42 38.08 1 813.83 焦粉 5.92 6.43 1.78 2.39 600.00 40.00 0.88 6.00 663.40 剩余污泥 5.34 1.02 1.32 1.33 1 270.00 — 0.69 3.12 1 282.80 毒性系数 5 5 1 5 40 30 2 10 注:—表示未检出。 -

[1] 杨文彪.我国炼焦产业现状及绿色发展研究[J]. 煤炭经济研究,2019,39(8):4-14.YANG W B. Research on the status and green development of China's coking industry[J]. Coal Economic Research,2019,39(8):4-14. [2] 李超, 郑文华, 杨华.焦化工业现状及热点技术[J]. 河北冶金,2019(12):1-6,23.LI C, ZHENG W H, YANG H. Present situation and hotspot technology of coking industry[J]. Hebei Metallurgy,2019(12):1-6,23. [3] 雍微, 刘伟军, 徐敏, 等.焦化行业污染源普查产排污系数的回顾与建议[J]. 环境影响评价,2020,42(4):27-30.YONG W, LIU W J, XU M, et al. Suggestions on the generation and discharge coefficient about the pollution source census in the coking industry[J]. Environmental Impact Assessment,2020,42(4):27-30. [4] XU S S, LIU W X, TAO S. Emission of polycyclic aromatic hydrocarbons in China[J]. Environmental Science & Technology,2006,40(3):702-708. [5] LIANG X J, GUO C L, LIAO C J, et al. Drivers and applications of integrated clean-up technologies for surfactant-enhanced remediation of environments contaminated with polycyclic aromatic hydrocarbons (PAHs)[J]. Environmental Pollution,2017,225:129-140. doi: 10.1016/j.envpol.2017.03.045 [6] SUN M, WANG L Y, ZHONG J J, et al. Chemical modification with aldehydes on the reduction of toxic PAHs derived from low temperature coal tar pitch[J]. Journal of Analytical and Applied Pyrolysis,2020,148:104822. doi: 10.1016/j.jaap.2020.104822 [7] 陈刚. 煤化工残渣中多环芳烃类污染物环境风险评估研究[D]. 沈阳: 东北大学, 2013. [8] 章丽萍, 刘青, 崔炜, 等.煤焦化固体残渣污染特性研究[J]. 洁净煤技术,2015,21(5):110-114.ZHANG L P, LIU Q, CUI W, et al. Pollution characteristics of residues from coal coking process[J]. Clean Coal Technology,2015,21(5):110-114. [9] MA Y H, SU W, WANG Q H, et al. Discharge and disposal of coking residue and distribution characteristics of PAHs in it[J]. Applied Mechanics and Materials, 2013, 448/449/450/451/452/453: 448-452. [10] ZHANG W H, WEI C H, AN G F. Distribution, partition and removal of polycyclic aromatic hydrocarbons (PAHs) during coking wastewater treatment processes[J]. Environmental Science Processes & Impacts,2015,17(5):975-984. [11] ZHANG W, FENG C, WEI C, et al. Identification and characterization of polycyclic aromatic hydrocarbons in coking wastewater sludge[J]. Journal of Separation Science,2012,35(23):3340-3346. doi: 10.1002/jssc.201200521 [12] 蒙小俊. 焦化废水生物处理过程有机组分转化与菌群结构研究[D]. 北京: 中国矿业大学(北京), 2016. [13] 孙峰, 翁焕新, 马学文, 等.污泥中重金属和多环芳烃(PAHs)的存在特性及其相互关系[J]. 环境科学学报,2008,28(12):2540-2548. doi: 10.3321/j.issn:0253-2468.2008.12.022SUN F, WENG H X, MA X W, et al. The characteristics of heavy metals and PAHs in sewage sludges and their relationships[J]. Acta Scientiae Circumstantiae,2008,28(12):2540-2548. doi: 10.3321/j.issn:0253-2468.2008.12.022 [14] 贺晶莹, 韦朝海, 冯春华, 等.焦化废水处理过程外排污泥中重金属形态特征及其潜在环境风险[J]. 环境工程学报,2013,7(1):79-85.HE J Y, WEI C H, FENG C H, et al. States distribution of heavy metals in coking wastewater sludge and its potential environmental risks[J]. Chinese Journal of Environmental Engineering,2013,7(1):79-85. [15] 刁春鹏. 焦化废水处理过程苯系物、苯胺类、重金属污染物的存在及去除特性分析[D]. 广州: 华南理工大学, 2012. [16] MU L, PENG L, LIU X F, et al. Emission characteristics of heavy metals and their behavior during coking processes[J]. Environmental Science & Technology,2012,46(11):6425-6430. [17] VANROOIJ J G, BODELIER-BADE M M, JONGENEELEN F J. Estimation of individual dermal and respiratory uptake of polycyclic aromatic hydrocarbons in 12 coke oven workers[J]. Occupational and Environmental Medicine,1993,50(7):623-632. doi: 10.1136/oem.50.7.623 [18] NISBET I C T, LAGOY P K. Toxic equivalency factors (TEFs) for polycyclic aromatic hydrocarbons (PAHs)[J]. Regulatory Toxicology and Pharmacology,1992,16(3):290-300. doi: 10.1016/0273-2300(92)90009-X [19] 庞绪贵, 代杰瑞, 陈磊, 等.山东省17市土壤地球化学背景值[J]. 山东国土资源,2019,35(1):46-56.PANG X G, DAI J R, CHEN L, et al. Soil geochemical background value of 17 cities in Shandong Province[J]. Shandong Land and Resources,2019,35(1):46-56. [20] HAKANSON L. An ecological risk index for aquatic pollution control. a sedimentological approach[J]. Water Research,1980,14(8):975-1001. doi: 10.1016/0043-1354(80)90143-8 [21] 徐争启, 倪师军, 庹先国, 等.潜在生态危害指数法评价中重金属毒性系数计算[J]. 环境科学与技术,2008,31(2):112-115. doi: 10.3969/j.issn.1003-6504.2008.02.030XU Z Q, NI S J, TUO X G, et al. Calculation of heavy metals' toxicity coefficient in the evaluation of potential ecological risk index[J]. Environmental Science & Technology,2008,31(2):112-115. doi: 10.3969/j.issn.1003-6504.2008.02.030 [22] 陈润甲, 田艳梅, 张钧, 等.山西省某焦化厂周边土壤中重金属污染评价及特征分析[J]. 天津农业科学,2020,26(6):79-84. doi: 10.3969/j.issn.1006-6500.2020.06.019CHEN R J, TIAN Y M, ZHANG J, et al. Evaluation and characteristic analysis of heavy metal pollution in soil of a coking plant in Shanxi Province[J]. Tianjin Agricultural Sciences,2020,26(6):79-84. doi: 10.3969/j.issn.1006-6500.2020.06.019 [23] 章丽萍, 刘青, 陈傲蕾, 等.煤间接液化固体废物污染特性研究[J]. 中国矿业大学学报,2015,44(5):931-936.ZHANG L P, LIU Q, CHEN A L, et al. Pollution characteristics of residues from indirect coal liquefaction[J]. Journal of China University of Mining & Technology,2015,44(5):931-936. [24] 李恩科, 程相利, 苍大强, 等.炼焦粉尘中多环芳烃的赋存特性[J]. 洁净煤技术,2009,15(6):93-96. doi: 10.3969/j.issn.1006-6772.2009.06.028LI E K, CHENG X L, CANG D Q, et al. Occurrence speciality of polycyclic aromatic hydrocarbons in coking dust[J]. Clean Coal Technology,2009,15(6):93-96. doi: 10.3969/j.issn.1006-6772.2009.06.028 [25] 王小娜, 黄相国, 陈朝中, 等. 焦粉环境风险评价及其环境管理[C]//2017中国环境科学学会科学与技术年会论文集. 厦门, 2017: 583-585. [26] 闫纪宪, 李清坤, 熊言开.浅谈焦化企业危险废物的产生情况和利用处置途径[J]. 山东化工,2021,50(1):236-238. doi: 10.3969/j.issn.1008-021X.2021.01.106YAN J X, LI Q K, XIONG Y K. Discussion on the generation and the route of utilization and disposal of hazardous waste in coking industry[J]. Shandong Chemical Industry,2021,50(1):236-238. doi: 10.3969/j.issn.1008-021X.2021.01.106 [27] WILSON S C, JONES K C. Bioremediation of soil contaminated with polynuclear aromatic hydrocarbons (PAHs): a review[J]. Environmental Pollution,1993,81(3):229-249. doi: 10.1016/0269-7491(93)90206-4 [28] 刘雷, 吴海珍, 王鸣, 等.典型表面活性剂对焦化污泥中富集多环芳烃的解吸[J]. 环境科学学报,2016,36(9):3282-3291.LIU L, WU H Z, WANG M, et al. Enhanced desorption of enriched polycyclic aromatic hydrocarbons from coking sludge using typical surfactants[J]. Acta Scientiae Circumstantiae,2016,36(9):3282-3291. [29] 任德贻, 赵峰华, 代世峰. 煤的微量元素地球化学[M]. 北京: 科学出版社, 2006. [30] 马学文, 翁焕新, 章金骏.中国城市污泥重金属和养分的区域特性及变化[J]. 中国环境科学,2011,31(8):1306-1313.MA X W, WENG H X, ZHANG J J. Regional characteristics and trend of heavy metals and nutrients of sewage sludge in China[J]. China Environmental Science,2011,31(8):1306-1313. [31] 雒昆利, 王五一, 姚改焕, 等.渭北石炭二叠系煤中汞的含量及分布特征[J]. 煤田地质与勘探,2000,28(3):12-14. doi: 10.3969/j.issn.1001-1986.2000.03.004LUO K L, WANG W Y, YAO G H, et al. Mercury content and its distribution in permo carboniferous coal in Weibei area, Shaanxi[J]. Coal Geology & Exploration,2000,28(3):12-14. □ doi: 10.3969/j.issn.1001-1986.2000.03.004 -

下载:

下载: